Silencing and noise-reducing coil pipe heat exchanger as well as ultra-silencing fan coil pipe and soundproofing heat exchanger

A heat exchanger, ultra-quiet technology, applied in noise suppression, evaporator/condenser, space heating and ventilation details, etc., can solve problems such as complicated installation procedures, high manufacturing costs or purchase costs, and achieve noise reduction Obvious effect, low cost, extremely cost effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

[0027] see Figure 1 to Figure 5 , which illustrate various embodiments of the invention.

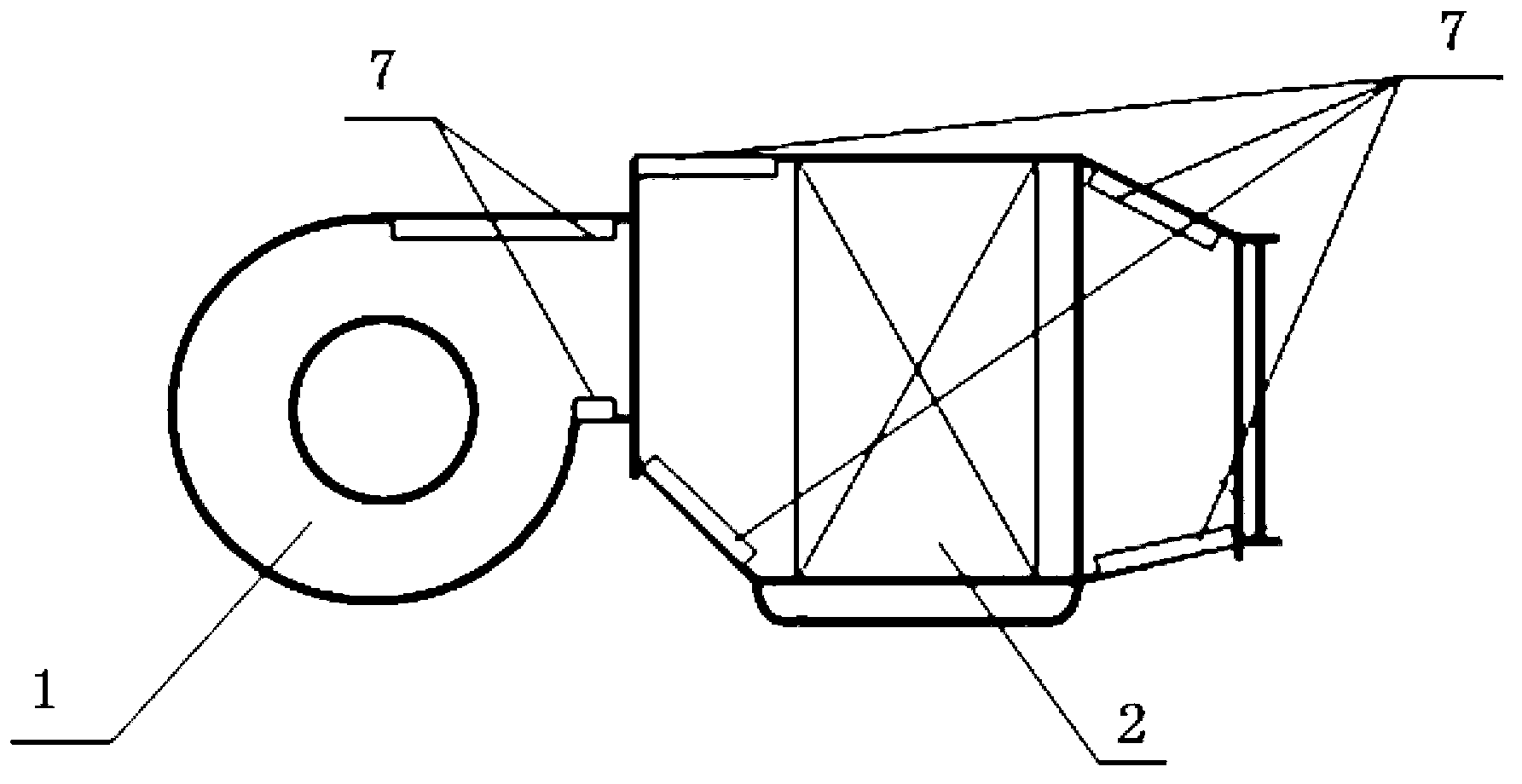

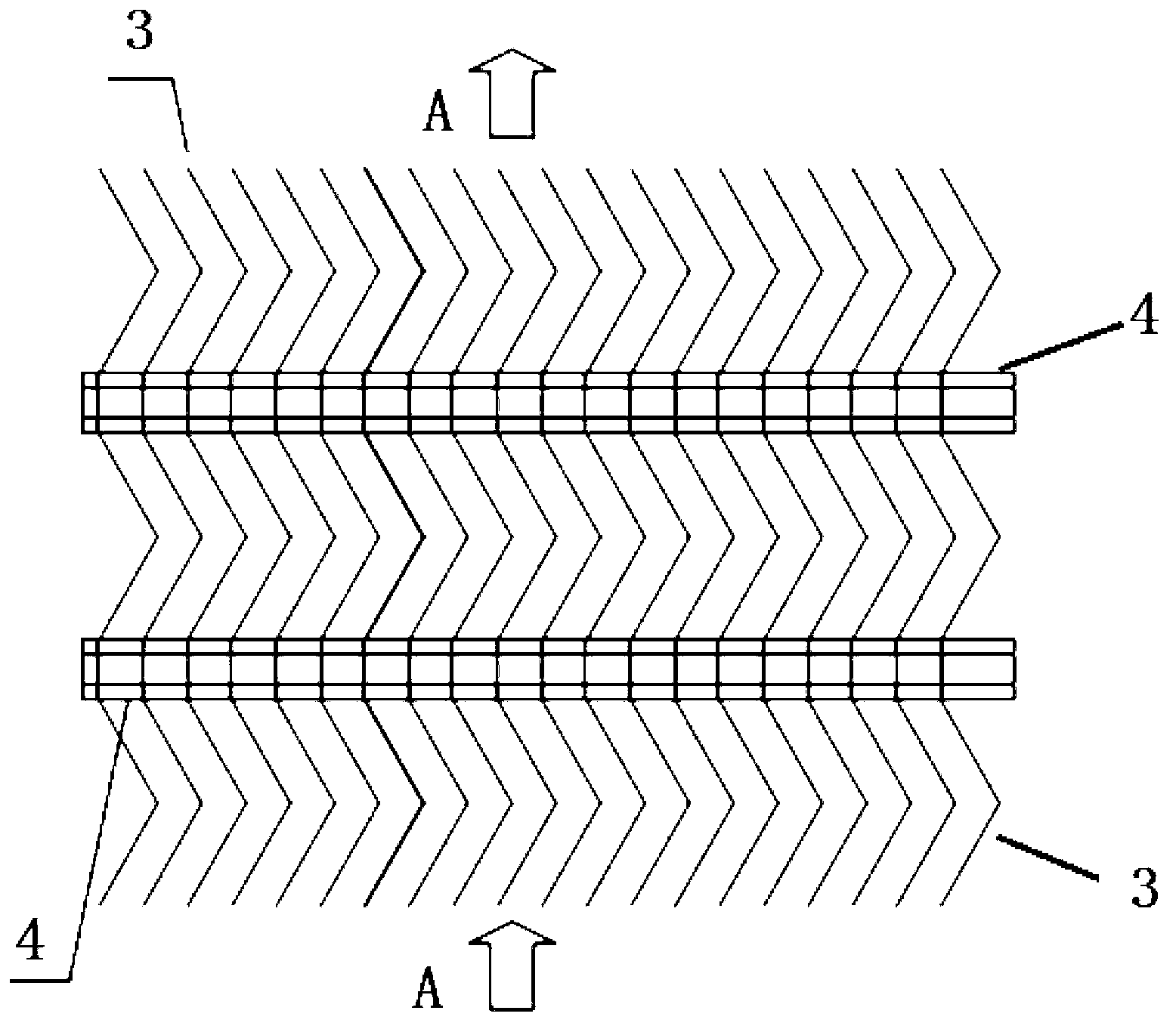

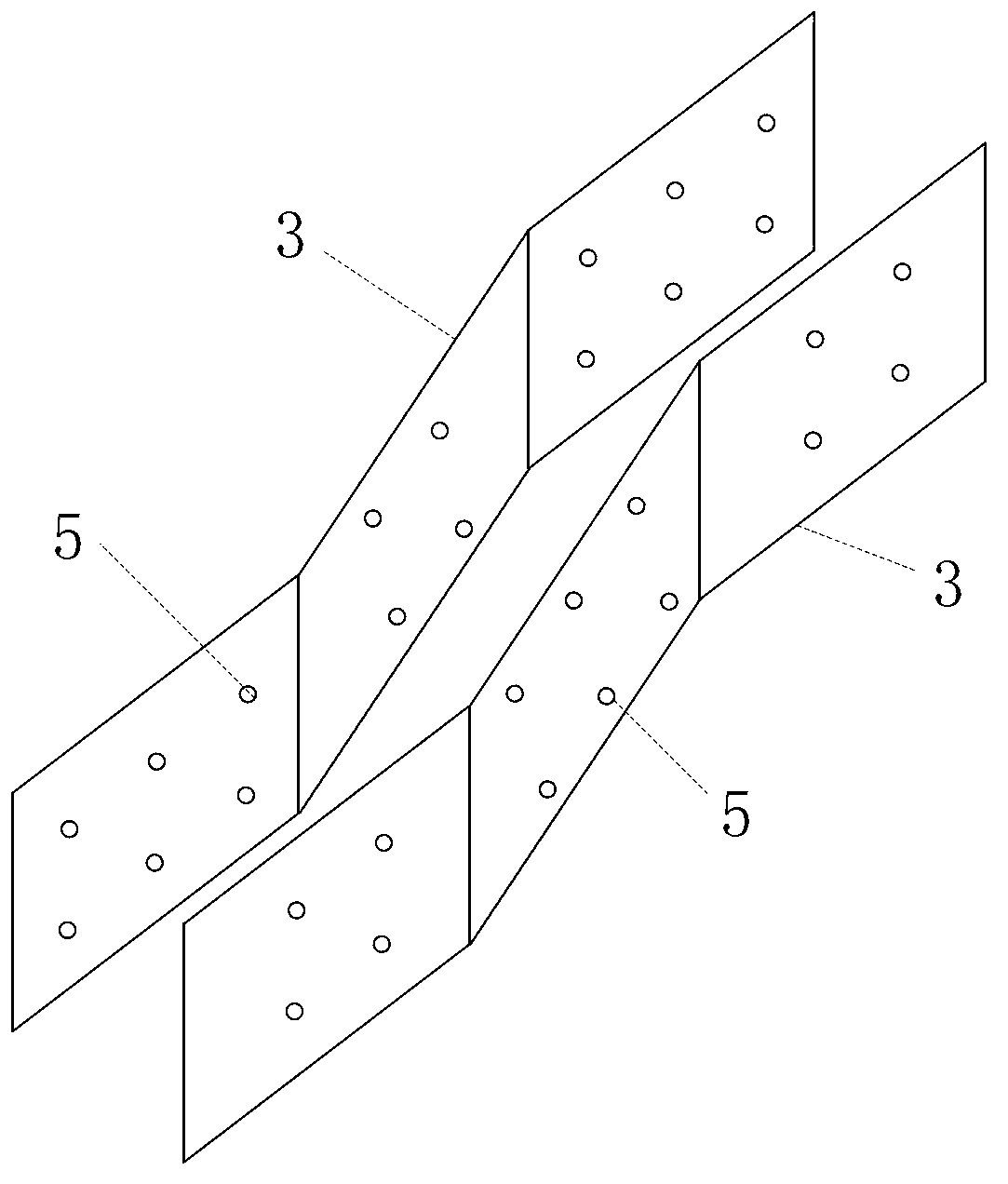

[0028] First, see figure 1 and figure 2 , an ultra-quiet fan coil unit of the present invention includes fan volutes 1 connected in sequence and water pipes 4 (such as figure 2 Shown) the silent and noise-reducing coil heat exchanger 2. Preferably, the inner wall of the fan volute 1 and the coil heat exchanger 2 is at least partially provided with a micro-hole plate sound absorption cavity 7 with a thickness of 3-8mm; the coil heat exchanger 2 of the present invention is provided with multiple sets of Bending type heat exchanging fins 3, the multiple sets of heat exchanging fins 3 are along the direction of air flow ( figure 2 A direction shown in ) is arranged to form multiple sets of air passages in the coil heat excha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com