Combined jet-flow control device for helicopter rotor blade and control method of combined jet-flow control device

A combined jet device and helicopter rotor technology, which is applied to rotorcraft, motor vehicles, transportation and packaging, etc., can solve the problems of weak off-design point working conditions, unsatisfactory control effects, increased resistance, etc., and achieve stall suppression Significant effects, avoiding adverse effects, improving work performance and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the objects and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

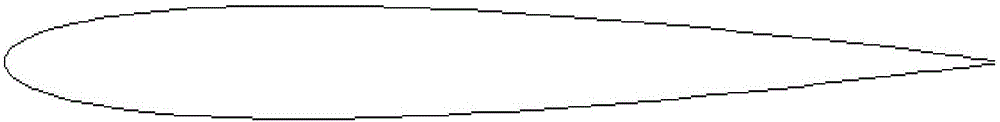

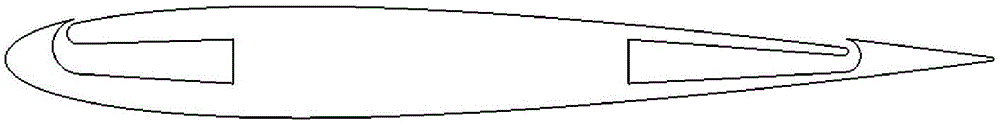

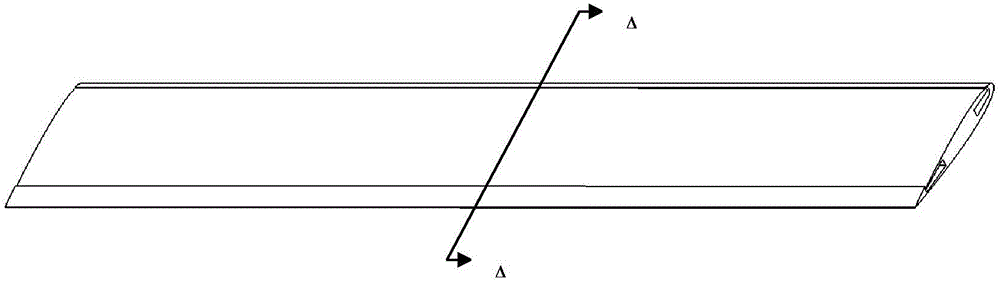

[0032] Such as Figure 2-4 Shown, the embodiment of the present invention provides a kind of combined jet flow control device for helicopter rotor blade, it is characterized in that, it comprises several blades whose geometric shape is NACA0012CFJ airfoil, and each blade is equipped with a combined jet flow device, so The combined jet device is continuously distributed along the span direction of the blade, and the combined jet device includes a high-pressure air chamber and a low-pressure air chamber. The high-pressure air chamber and the low-pressure air chamber are connected to the air pump device inside the helicopter through the airflow pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com