Eddy generator, wind turbine blade with eddy generator and installation method of eddy generator

A vortex generator and wind turbine blade technology, applied in the field of wind power, can solve the problems of inaccurate installation position of the vortex generator and poor effect of the vortex generator, and achieve accurate and reliable installation and positioning process, high installation efficiency, and reduced aerodynamic noise. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

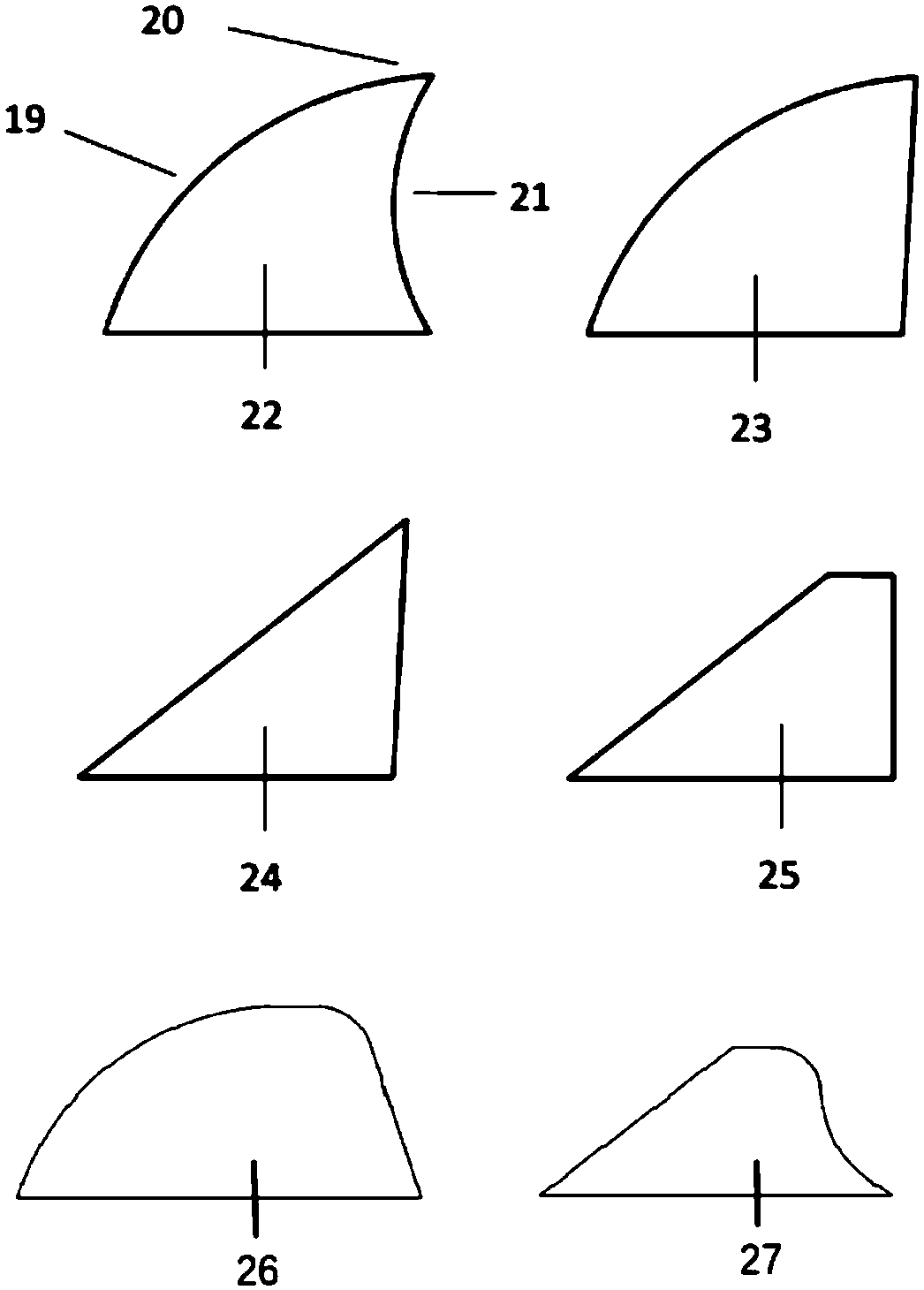

[0076] Such as image 3 As shown, the traditional vortex generator fins 22 can be obtained based on bionic simplification, where 19 is the leading edge of the fin (the windward side of the fin), 20 is the top of the fin, and 21 is the trailing edge of the fin (the leeward side of the fin). Considering the convenience of processing technology and structural reliability, the fins are deformed into 23. According to the patent documents of the prior art, the shapes of existing vortex generator fins are shown in 24, 25, 26 and 27. Considering the reduction of resistance and the convenience of production, this embodiment provides a vortex generator and a wind turbine blade with a vortex generator, wherein the shape of the fins of the vortex generator is as follows: Figure 4 As shown, the top corners of the fins 28 are made into a circular arc shape to reduce the partial separation of the airflow and reduce the resistance.

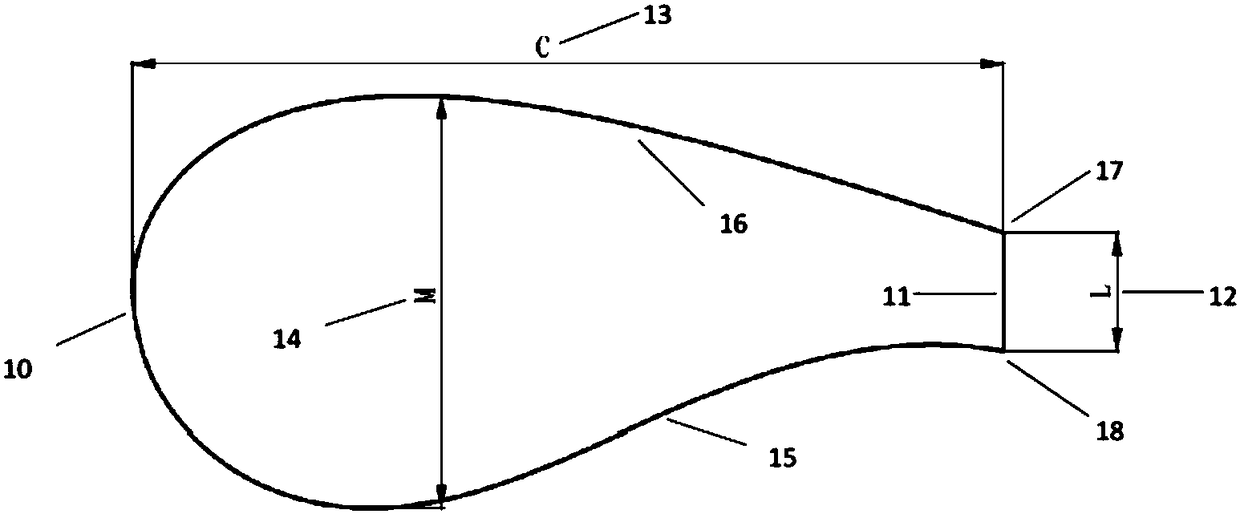

[0077] In this embodiment, the profile of the airfoil use...

Embodiment 2

[0090] This embodiment provides a method for installing the vortex generator of the blade that has not been installed and operated.

[0091] Installation preparation: the installation environment temperature is required to be above 5°C, the higher the temperature, the better the bonding effect of the adhesive; the preparation is as follows Figure 18 The chordwise positioning clip 76 of the vortex generator shown in the figure requires that the material of the clip 76 is aluminum in terms of strength and light weight, and 77 is the positioning position of the trailing edge of the airfoil. Note that a 10-20 mm height increase is appropriately reserved for positioning 77 of the trailing edge Positioning reliability; water-based marker pen, 800-grit sandpaper, 50m long tape measure, powder or ink fountain marker, industrial alcohol.

[0092] Installation process:

[0093] 1) Properly adjust the position of the blade so that the suction surface of the blade (corresponding to the ...

Embodiment 3

[0102] This embodiment provides a method for installing a vortex generator on an installed wind turbine blade.

[0103] Installation preparation: a set of maintenance platform or hanging basket system, safety belts, safety ropes and safety helmets for high-altitude operations, walkie-talkies; chord-direction positioning clamps for vortex generators; water-based markers, 800-grit sandpaper, 50m long tape measure, powder bucket Or ink fountain scriber, industrial alcohol; the ambient temperature is higher than 8 ℃, the wind speed of the wind field should be less than 8 m / s, and the installation work cannot be carried out in rainy, foggy and other poor visibility weather.

[0104] Installation process:

[0105] 1) Lock the impeller and confirm with the team members, and monitor that everything is normal, the engine room maintenance has been opened, the emergency stop has been photographed, and the yaw has been closed;

[0106] 2) Delineate the safety range of on-site constructio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com