Blade boundary layer flow control system and wind power generating set including same

A flow control and boundary layer technology, applied in the direction of wind motor combination, wind engine, and wind engine consistent with the wind direction, can solve the problems of losing the meaning of power increase, energy loss, etc., to increase power generation, delay stall, Effect of suppressing blade boundary layer separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] like Figure 1-Figure 7 As shown, this embodiment discloses a blade boundary layer flow control system, wherein the blade boundary layer flow control system includes a fan blade, a first guide section and a second guide section.

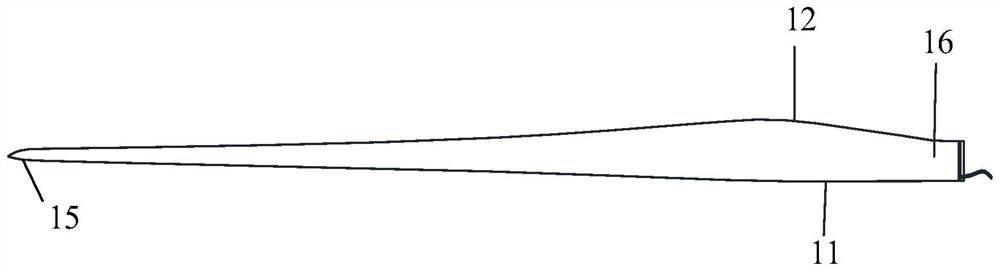

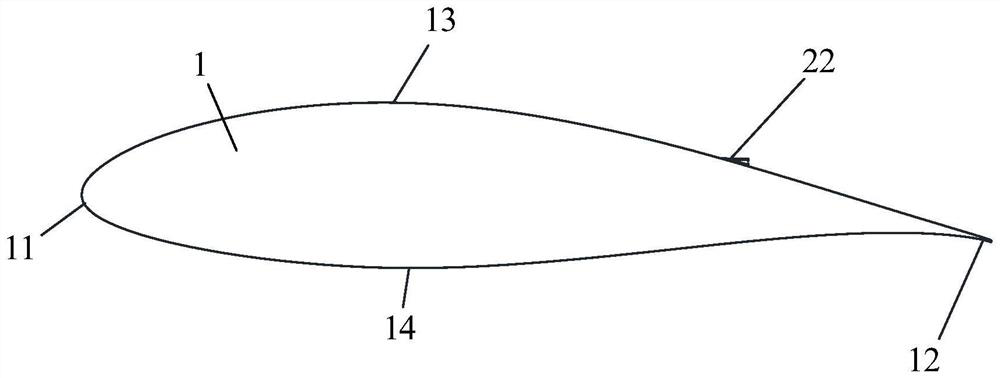

[0044] like figure 1 and image 3As shown, the blade boundary layer flow control system of this embodiment includes a fan blade 1, which is an elastic body and has a suction surface 13, a pressure surface 14, a blade root end 16, a blade tip 15, a blade leading edge 11 and a blade rear Edge 12, wherein a blade cavity 17 is formed inside the fan blade 1.

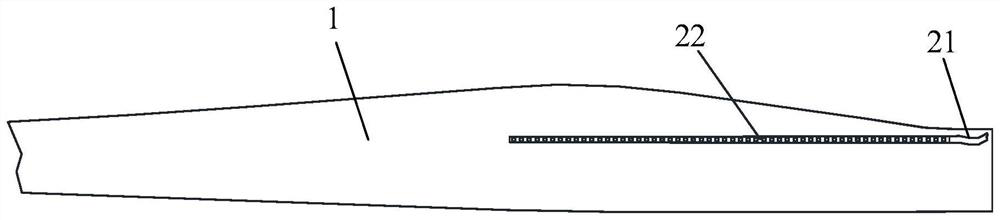

[0045] like figure 1 , Figure 5 and Figure 7 As shown, the blade boundary layer flow control system of this embodiment includes a first guide section 21 and a second guide section 22 . Wherein, the first guide section 21 communicates with the blade cavity 17 . like figure 1 and Figure 4 As shown, the second guide section 22 communicates with the first guide section 21, and the sec...

Embodiment 2

[0061] like Figure 8 and Figure 9 As shown, the second guide section 22 is provided on the side of the suction surface 13 close to the blade trailing edge 12 in this embodiment, and the vortex generator 6 is provided on the side of the suction surface 13 close to the blade leading edge 11 . The vortex generator 6 disposed near the leading edge 11 of the blade can further improve the aerodynamic performance of the fan blade 1 .

[0062] In this embodiment, the length of the second guide section 22 on the side near the trailing edge 12 of the blade is consistent with the length of the vortex generator 6 on the side near the leading edge 11 . Other structures in this embodiment are the same as those in Embodiment 1, so details are not repeated here.

Embodiment 3

[0064] like Figure 10 and Figure 11 As shown, in this embodiment, the side of the suction surface 13 close to the trailing edge 12 of the blade is provided with a second guide section 22 , and the side of the suction surface 13 close to the blade leading edge 11 is also provided with a second guide section 22 . The second guide section 22 disposed near the leading edge 11 of the blade can further improve the aerodynamic performance of the fan blade 1 .

[0065] In this embodiment, the length of the second guide section 22 on the side near the trailing edge 12 of the blade is consistent with the length of the second guide section 22 on the side near the leading edge 11 . Other structures in this embodiment are the same as those in Embodiment 1, so details are not repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com