Solenoid valve device and automatic paper feeder using same

An automatic paper feeding, solenoid valve technology, applied in valve device, valve operation/release device, valve lift and other directions, can solve the problems of collision sound, human unpleasant, etc. Collision sound effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

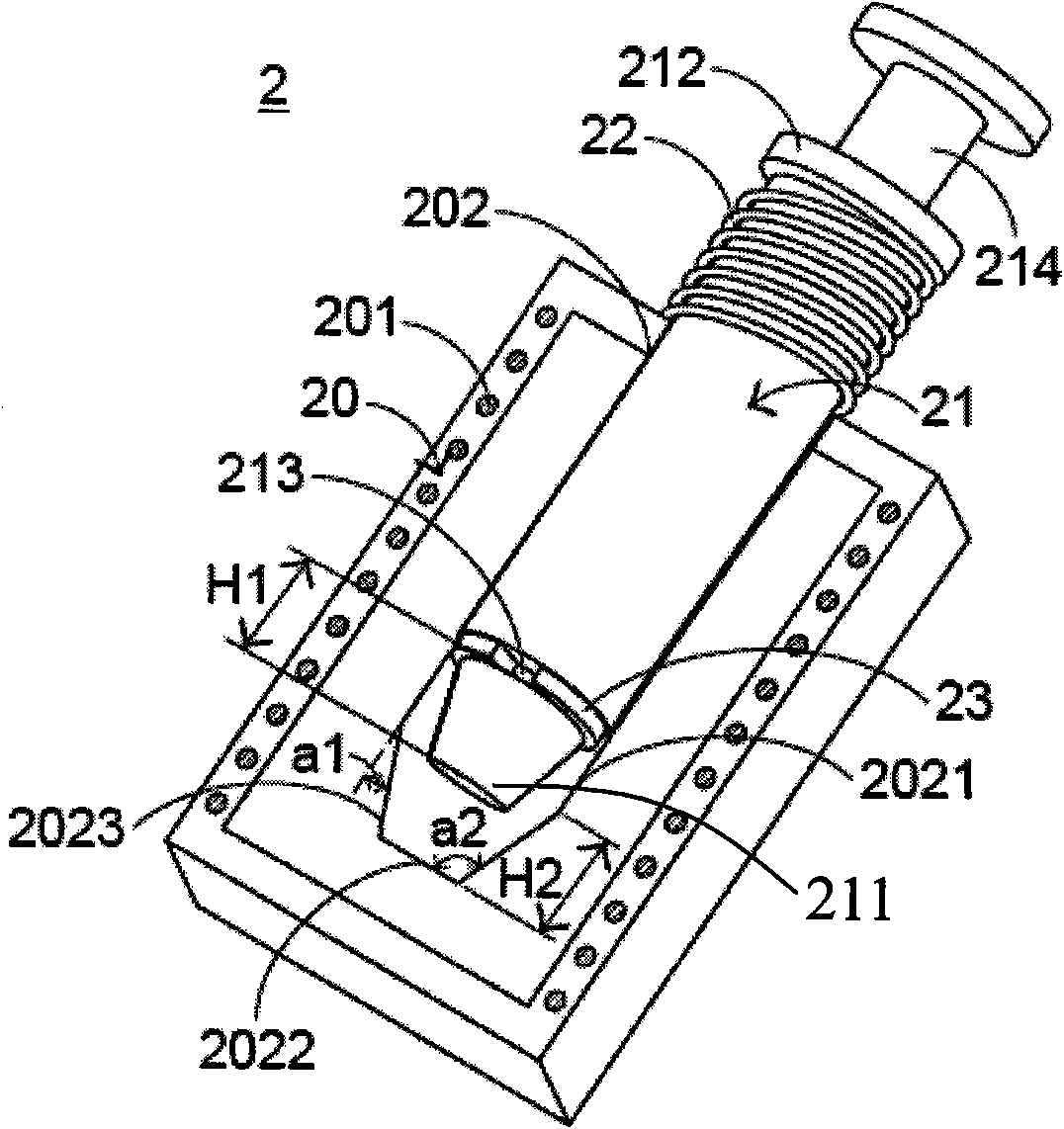

[0058] In order to reduce the collision sound, the electromagnetic valve device 2 of the present invention is specially provided with a noise reduction device, please refer to figure 2 , which is a structural schematic diagram of a preferred embodiment of the solenoid valve device of the present invention. The solenoid valve device 2 includes a solenoid valve body 20 , a solenoid valve shaft 21 , a spring 22 , an annular groove 213 and a muffler ring 23 . The solenoid valve body 20 has a solenoid coil 201 and a groove 202, the solenoid coil 201 surrounds the solenoid valve body 20 to generate magnetic force, and the groove 202 includes a groove side wall 2021, a groove bottom 2022 and a groove inner wall 2023, wherein the groove The inner wall 2023 is located between the groove side wall 2021 and the groove bottom 2022, and there is an angle a1 between the groove inner wall 2023 and the groove side wall 2021, and there is another angle between the groove inner wall 2023 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com