Rope drag chain

A traction chain and cable technology, applied in the field of cable traction chain, can solve the problems of easy wear and plastic powder production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following description is merely explanatory in nature and is not intended to limit the invention or its application and uses in any way.

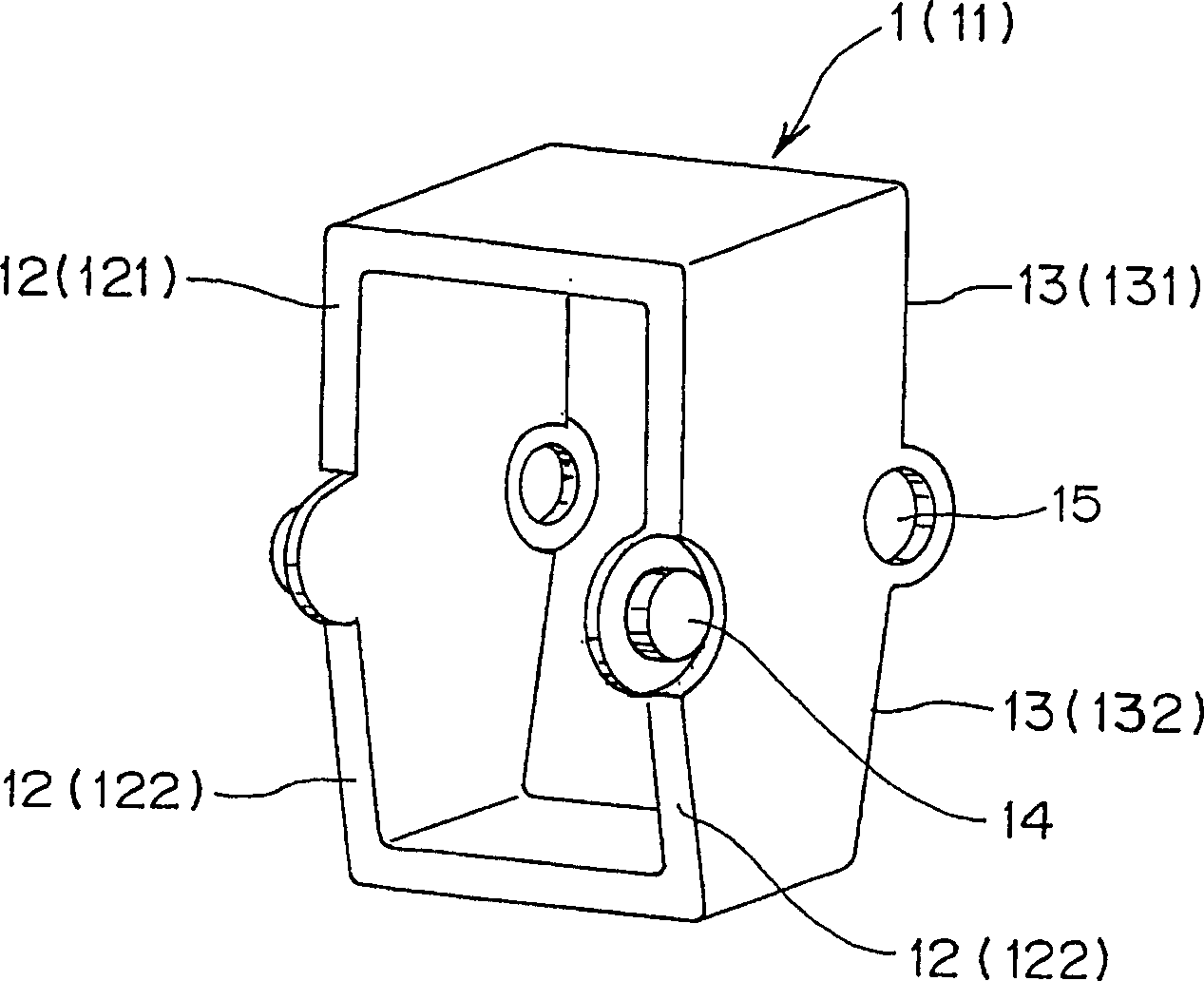

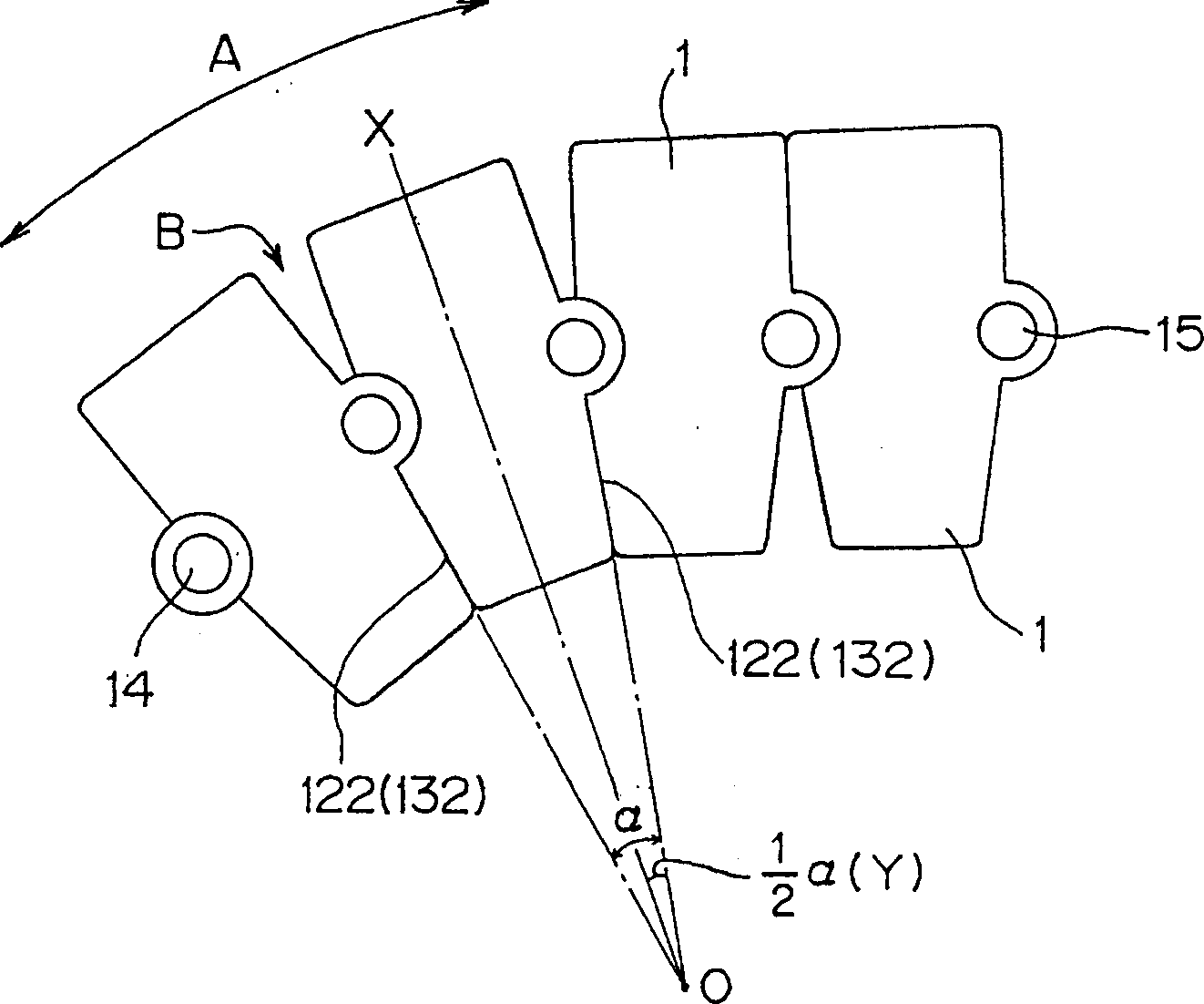

[0029] Referring now to the diagram, and in particular to figure 1 , shows in a perspective view the inner connection part 1 of the cable pulling chain according to the first embodiment of the invention. The inner connecting member 1 is composed of a hollow rectangular ring member 11 which is molded from synthetic resin. The hollow annular inner connector 1 (11) has a pair of connecting pins 14 formed at its front end 12 (at the figure 1 In the center of the left side), a pair of diametrically opposite pinholes 15 are formed in a diametrically opposite relationship at its rear end 13 (in figure 1 in the center of the right). The connecting pin 14 and the connecting hole 15 of the inner connecting piece 1 are respectively rotatably engaged with the pin holes 15 and the connecting pin 14 of the inner connecting piece 1 placed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com