Strong magnetic fastening device for leakage stoppage under pressure in high-temperature environment and chemical equipment

A high-temperature environment, fastening device technology, applied to mechanical equipment, engine seals, pipes/pipe joints/pipe fittings, etc., can solve the problems of difficult installation of plugging parts under pressure and inability to use immediate leak elimination methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

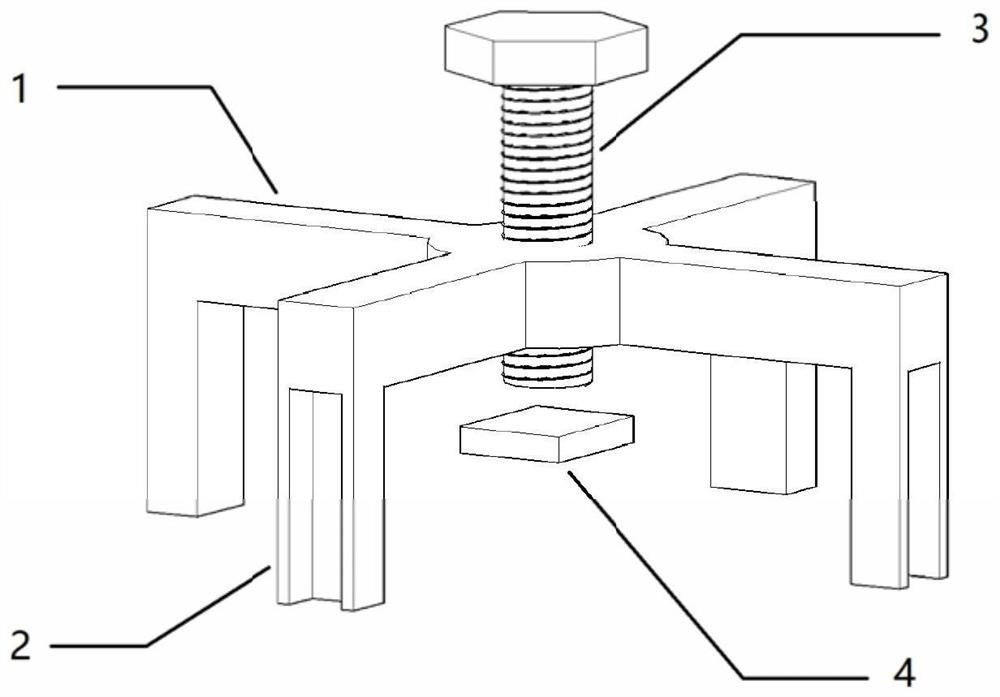

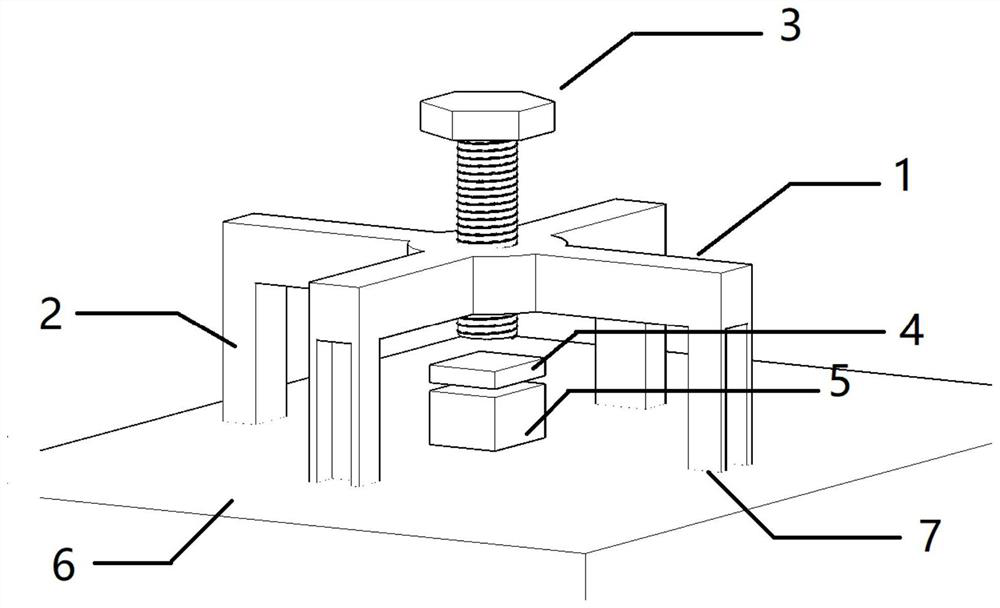

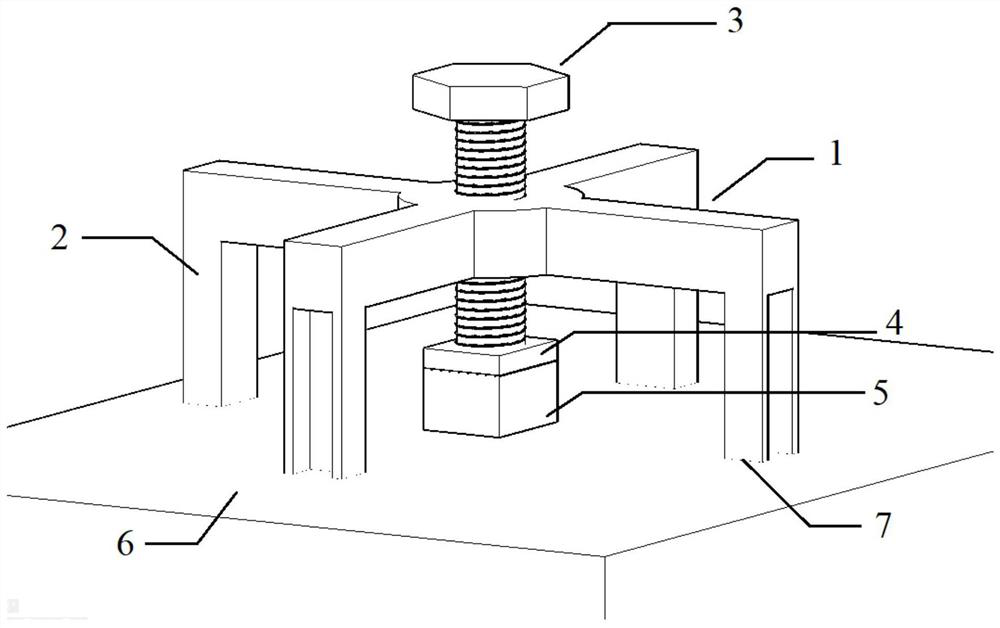

[0021] The present invention provides a strong magnetic tape pressure plugging fastening device in a high temperature environment, including a support frame, a fastener 3 and a strong magnetic pressure plate 4, wherein the support frame can be fixed to the leakage body 6, and the fastener 3 is connected to The support frame can also press the strong magnetic pressure plate 4 onto the leak-proof strong magnet 5 on the leakage body 6 .

[0022] combine Figure 1-3 , through the above scheme, under the premise of strong magnetic temporary leakage elimination, this design connects the support frame and the leaking body by welding. The present invention uses fastene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com