Multi-layer sealing ball valve for rail transit

A multi-layer sealing, rail transit technology, applied in valve details, valve device, valve shell structure, etc., can solve the problems of easy sealing performance to be affected by temperature changes, easy attenuation of installation torque, complex structure, etc., to reduce cleaning and maintenance. Cost, prevent destructive deformation, reduce leakage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

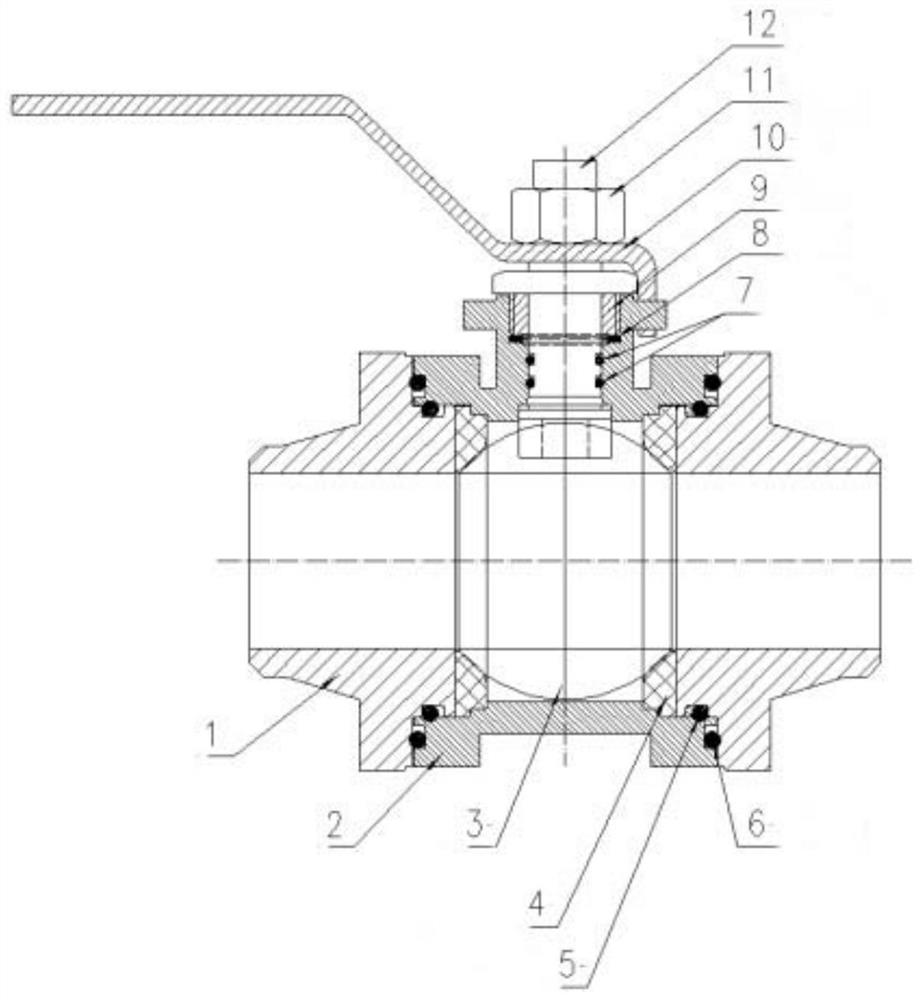

[0032] Such as figure 1 As shown, the present invention adopts the following technical solutions to realize: a welded ball valve with a multi-layer sealing structure used in the field of rail transit, consisting of a valve cover 1, a valve body 2, a ball 3, a gasket 4, a valve stem 12, and a valve stem Nut 11, handle 10, seal and other fasteners. The valve body 2 is located at the upper and lower ends of the welded ball valve. The valve body 2 is in sealing connection with the valve cover 1 and the valve stem 12. The valve stem 12 is set in the middle of the upper valve cover 1. The handle 10 is installed on the valve stem 12 and fixed with the valve stem nut 11. . Seals and fasteners include radial O-rings 5 on the bonnet, axial O-rings 6 on the valve body, radial O-rings 7 on the valve stem, and composite gaskets 8 on the valve body. In this embodiment, as a preferred implementation manner, the handle and the valve stem are fixed by a valve stem nut, which can be disasse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com