Composite blade set and cutting mechanism used therefor

A composite knife and composite technology, which is applied in metal processing and other directions, can solve the problems of reduced production capacity, affecting efficiency, and insufficient rigidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

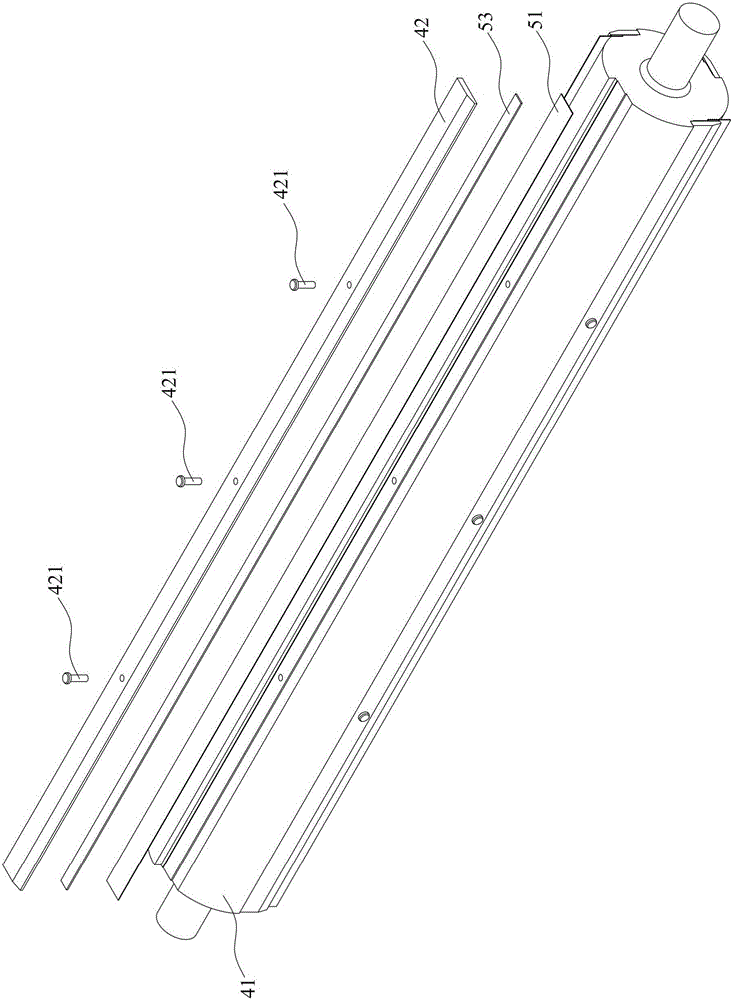

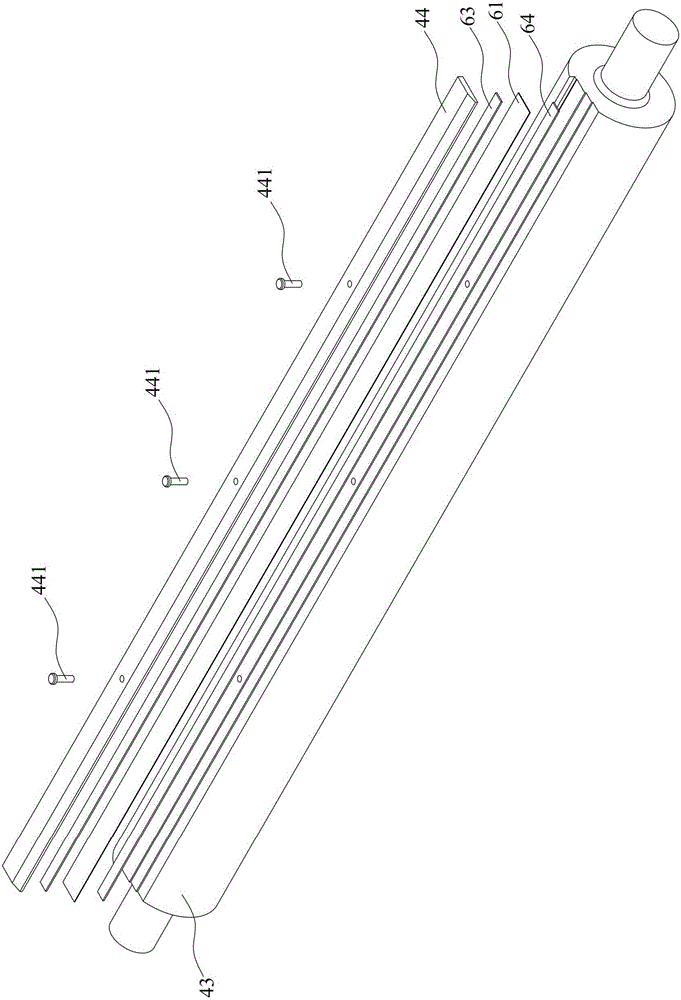

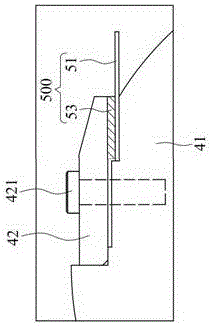

[0051] Below in conjunction with accompanying drawing, structural principle and working principle of the present invention are specifically described:

[0052]Please refer to FIG. 1(A), FIG. 1(B), and FIG. 1(C), which are schematic structural diagrams of various embodiments of the composite blade set of the present invention. The composite blade set 100 of the present invention is set in a cutting mechanism, which is a combination of a blade 11 and at least one elastic layer 121 , 122 , 123 made of the same material or different materials. The present invention will select to stick one or more than one layer of elastic layers 121, 122 and / or 123 on the appropriate surface of the blade 11 (such as on the edge face 111 of part and / or on the back 112). In addition, in the embodiment of the present invention, each elastic layer 121 , 122 , 123 can be adhered on the surface of the blade 11 by a viscous substance (for example: glue).

[0053] As shown in the embodiment of FIG. 1(...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com