Airbag horn switch structure and automobile

A switch structure, airbag technology, applied in vehicle components, sound signal devices, signal devices, etc., can solve problems such as poor user experience, increase replacement costs, reduce service life, etc., to improve comfort and customer perception experience, The effect of reducing collision noise and improving comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

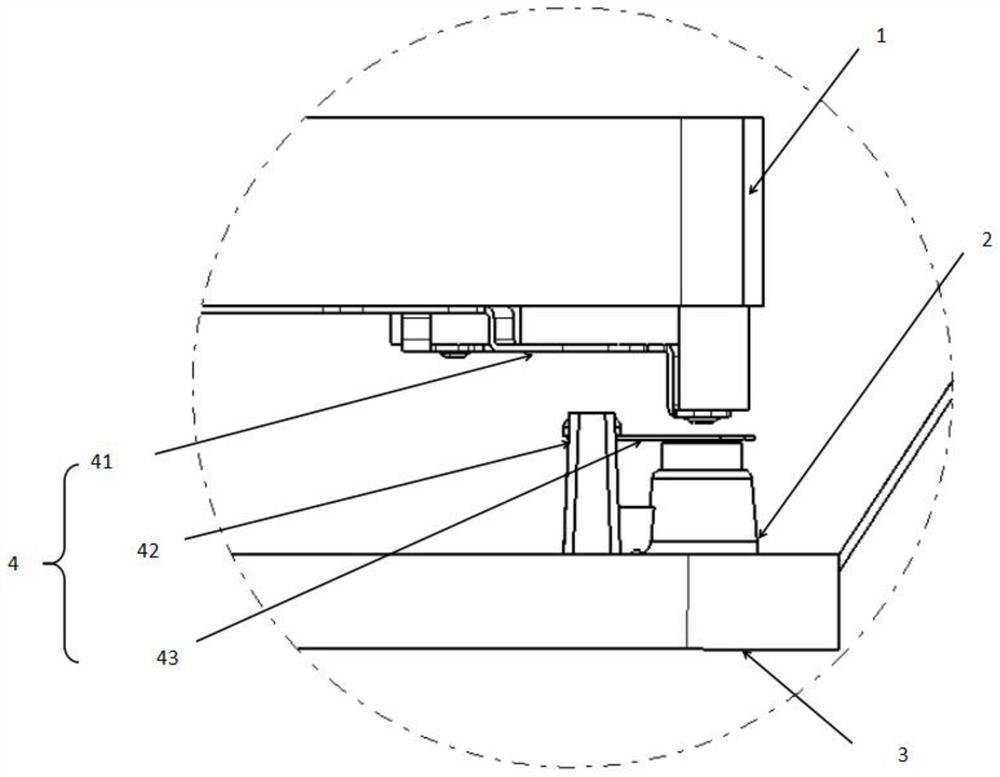

[0026] The first embodiment provides an airbag horn switch structure, including an airbag support plate 1, a buffer mechanism 2, a steering wheel frame 3, a conductive mechanism 4 and a spring mechanism.

[0027] Such as figure 1 As shown, one end of the airbag pallet 1 and one end of the steering wheel frame 3 are connected to the spring mechanism, and a gap is provided between the other end of the airbag pallet 1 and the other end of the steering wheel frame 3, and the buffer The mechanism 2 is located at the gap, the buffer mechanism 2 is fixed on the steering wheel frame 3 , and the buffer mechanism 2 is used to absorb the impact force of the airbag tray 1 .

[0028] Specifically, the buffer mechanism 2 includes a buffer member, the buffer member is a foam structure, the foam structure is made of rubber material, and the hardness of the rubber material is lower than 68HA, so the material texture is relatively soft, which can buffer the impact Force, the role of absorbing ...

Embodiment 2

[0039] The second embodiment provides an automobile, including an automobile power supply, a steering column, and the airbag horn switch structure described above.

[0040] Specifically, the airbag horn switch structure includes an airbag support plate 1, a buffer mechanism 2, a steering wheel frame 3, a conductive mechanism 4 and a spring mechanism.

[0041] Specifically, one end of the airbag tray 1 and one end of the steering wheel frame 3 are connected to the spring mechanism, and a gap is provided between the other end of the airbag tray 1 and the other end of the steering wheel frame 3, and the buffer The mechanism 2 is located at the gap, the buffer mechanism 2 is fixed on the steering wheel frame 3 , and the buffer mechanism 2 is used to absorb the impact force of the airbag tray 1 .

[0042] Specifically, the buffer mechanism 2 includes a buffer member, the buffer member is a foam structure, the foam structure is made of rubber material, and the hardness of the rubber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com