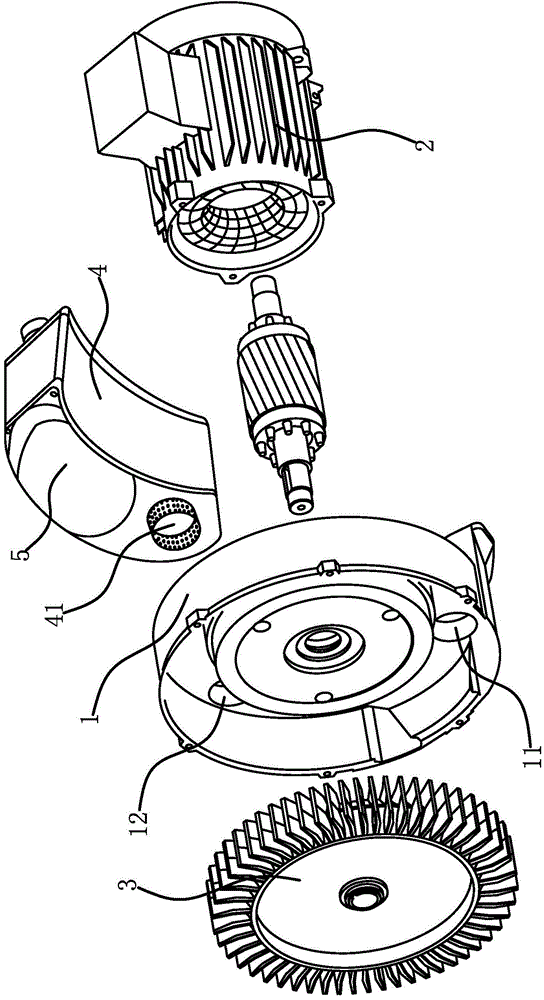

Silencer of high-pressure blower

A high-pressure blower and muffler technology, which is applied to the components of the pumping device for elastic fluids, mechanical equipment, machines/engines, etc. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

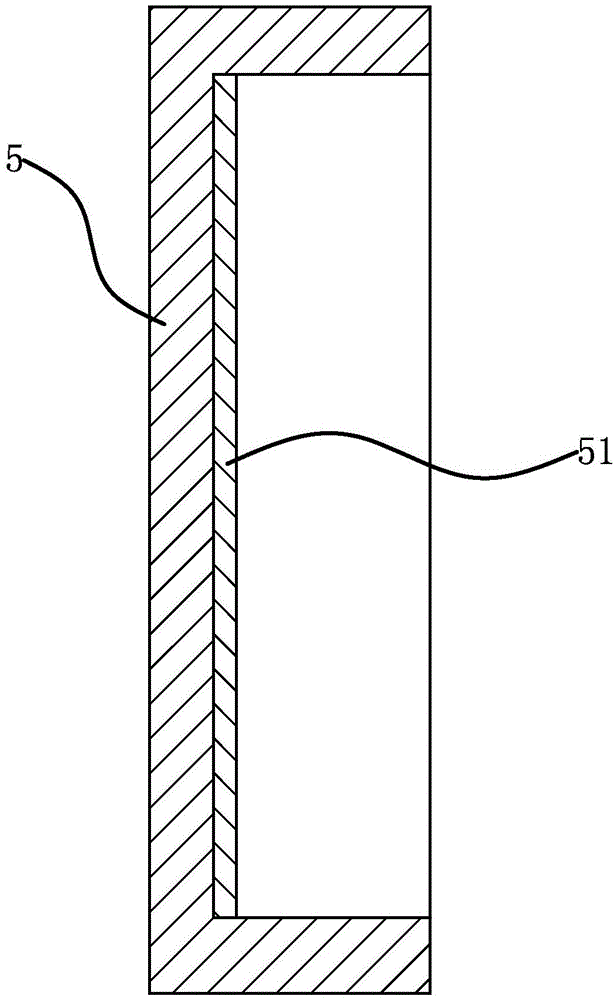

[0038] The raw materials were weighed according to the components and parts by weight of the sound-absorbing coating in Example 1 in Table 1. Under the condition of stirring, dissolve the dispersant, preservative, filler and polysiloxane in 4 parts of water and stir well. Then add acrylic resin, film-forming aid and 4 parts of water under stirring condition and stir evenly. Then divide the weighed hollow plastic balls into 5 equal parts and add them in 5 times. After each addition, they need to be stirred evenly before adding the remaining hollow plastic balls. Finally, add the remaining 4 parts of water and stir evenly to obtain the sound-absorbing coating. Finally, put the prepared sound-absorbing paint into the hopper of the spray gun, move the spray gun in one direction, and spray on the inner surface of the cover plate 5 step by step for 4 times, and dry to obtain the sound-absorbing coating 51 .

Embodiment 2

[0040] The raw materials were weighed according to the components and parts by weight of the sound-absorbing coating in Example 2 in Table 1. Under the condition of stirring, dissolve the dispersant, preservative, filler and polysiloxane in 6 parts of water and stir evenly. Then add acrylic resin, coalescent and 6 parts of water under stirring condition and stir evenly. Then divide the weighed hollow plastic balls into 3 equal parts and add them in 3 times. After each addition, they need to be stirred evenly before adding the remaining hollow plastic balls. Finally, add the remaining 6 parts of water and stir evenly to obtain the sound-absorbing coating. Finally, put the prepared sound-absorbing paint into the hopper of the spray gun, move the spray gun in one direction, and spray on the inner surface of the cover plate 5 step by step twice, and dry to obtain the sound-absorbing coating 51 .

Embodiment 3

[0042] The raw materials were weighed according to the components and parts by weight of the sound-absorbing coating in Example 3 in Table 1. Under the condition of stirring, dissolve the dispersant, preservative, filler and polysiloxane in 8 parts of water and stir evenly. Then add acrylic resin, film-forming aid and 8 parts of water under stirring condition and stir evenly. Then divide the weighed hollow plastic balls into 4 equal parts and add in 4 times. After each addition, it needs to be stirred evenly before adding the remaining hollow plastic balls. Finally, add the remaining 8 parts of water and stir evenly to obtain the sound-absorbing coating. Finally, put the prepared sound-absorbing paint into the hopper of the spray gun, move the spray gun in one direction, and gradually spray five times on the inner surface of the cover plate 5, and dry to obtain the sound-absorbing coating 51.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com