Composite exhausting evacuation silencer

A muffler and composite technology, applied in the direction of pipes/pipe joints/fittings, mechanical equipment, pipe components, etc., can solve problems such as affecting thinking and mental concentration, being higher than eight or ninety decibels, affecting physical health, etc. The effect of reducing injection noise, increasing the contact area, and excellent noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

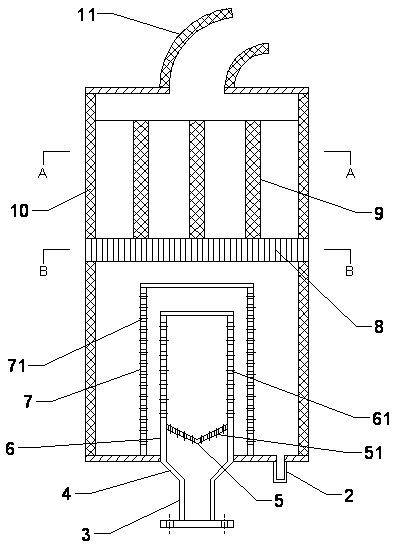

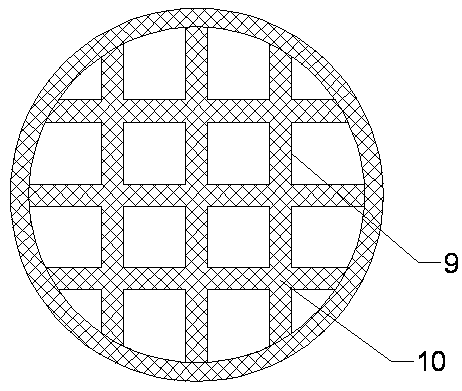

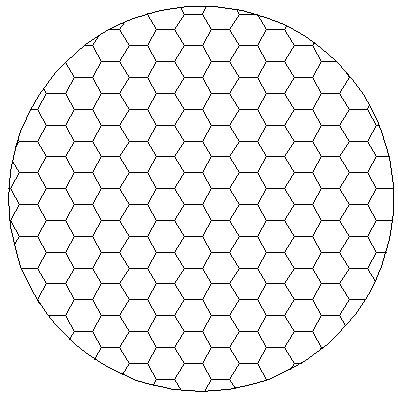

[0019] see Figure 1 ~ Figure 3 , a compound exhaust and venting muffler, which is composed of an air intake section, a muffler section, and an exhaust section. The first-level muffler includes a throttling and pressure-reducing pipe 6, the small-hole injection pipe 7 and the tapered orifice plate 5, and the second-level muffler is a honeycomb resistive muffler, which consists of multiple The two mufflers 9 are arranged vertically to each other. The honeycomb resistive muffler section greatly improves and improves the high-frequency muffler characteristics. 4 and the intake straight pipe 3. The top opening of the muffler cylinder 1 is connected with an exhaust section. The exhaust section is an exhaust elbow 11 with a layer of resistive sound-absorbing material 10 attached to the inner wall. The exhaust elbow 11 is changed by changing The airflow di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com