Fabric ring drum device capable of expanding and contracting and used for tire forming

A technology of expansion and contraction and tire molding, which is applied in the field of tire molding rubber machines, can solve the problems of limited tire production efficiency, low degree of automation, and complicated coating process, and achieves the direct and clear working form, improved safety, and low failure rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] specific implementation plan

[0016] The present invention will be further described below according to the accompanying drawings and examples.

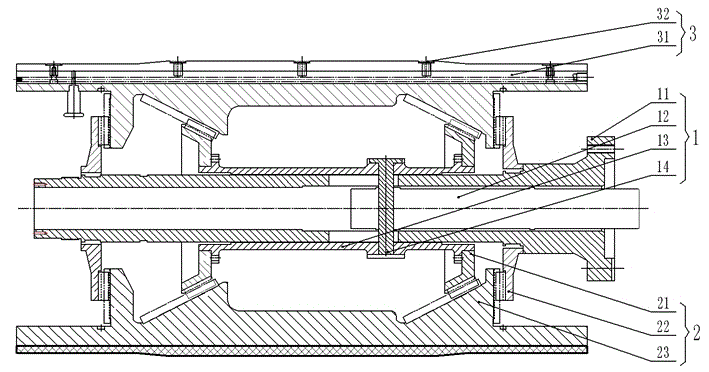

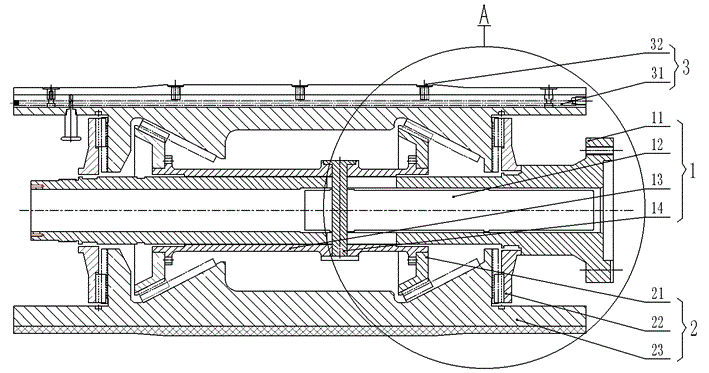

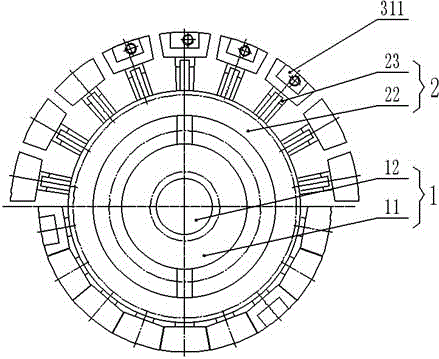

[0017] combine Figure 1~Figure 3 As shown, an expandable and contractable cloth ring drum device for tire building, including a main sliding shaft assembly 1, a linear guide rail assembly 2 and a capsule fixing mechanism 3; the main sliding shaft assembly 1 passes through the linear guide rail assembly 2 and the capsule fixing mechanism 3 Connected, wherein the main sliding shaft kit 1 contains the rotating main shaft 11, the driving rod 12, the sliding bushing 13 and the connecting pivot 14, and the linear guide assembly 2 contains 2 sets of inclined guide rails 21, 2 sets of radial guide rails 22 and 18 drums The plate 23, the capsule fixing mechanism 3 includes 6 moldings 31 and 4 vacuum suction nozzles 32;

[0018] combine Figure 4 , the rotary spindle 11 includes a rotary spindle body 111 and a waist-shaped groove 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com