Vertical polishing machine

A polishing machine, vertical technology, applied in the field of polishing machines, can solve problems such as being unsuitable for small businesses or private individuals, expensive, and the structure of polishing machines is complicated.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

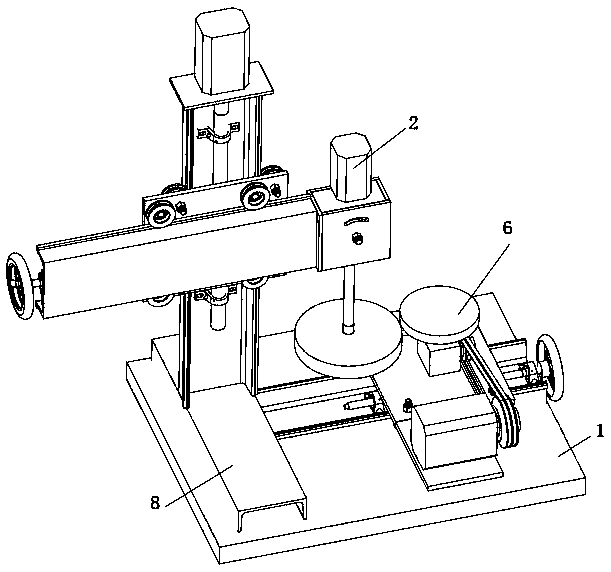

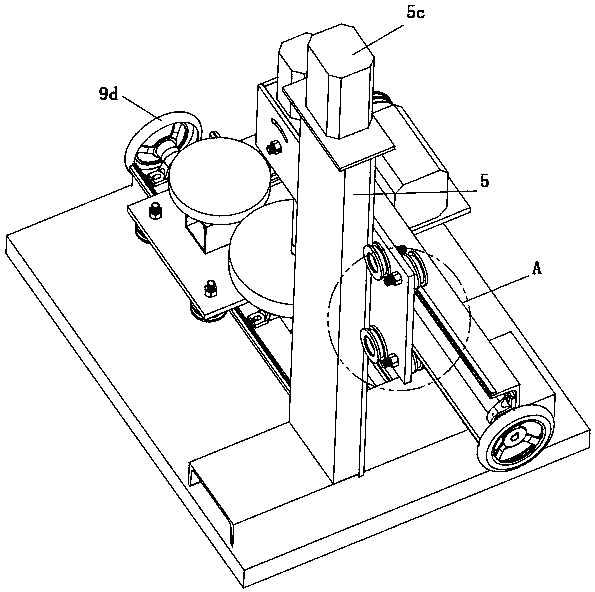

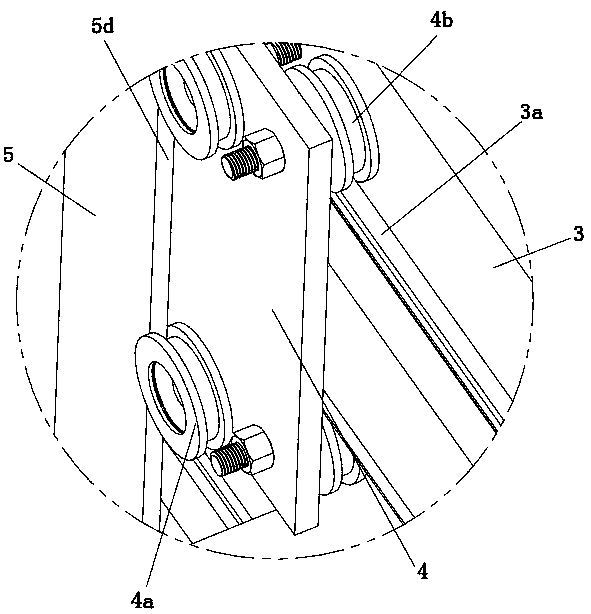

[0023] refer to Figure 1 to Figure 7 A vertical polishing machine shown includes a supporting table 1, a first polishing part 2 and a second polishing part 6, the working surface of the supporting table 1 is a rectangular structure, and the top of the supporting table 1 is provided with a first adjustment Seat 5 and the second adjustment seat 9, the first adjustment seat 5 is vertically arranged on one end of the support platform 1 through the heightening plate 8, and the second adjustment seat 9 is horizontally arranged on the top of the support platform 1 and is located at the height of the support platform. In the middle section of the plate 8, the first polishing member 2 includes a first motor 2a, a length adjustment seat 3 and a first bearing plate 4, the back side of the first bearing plate 4 can vertically ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com