Patents

Literature

61results about How to "Good throwing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sludge composting method

ActiveCN101781131AEasy to getShort fermentation timeBio-organic fraction processingClimate change adaptationEcological environmentSludge compost

The invention provides a sludge composting method, and relates to a sludge treatment method which comprises the steps of preferable accessory selection, CK21 fungus spraying inoculation, heavy metal passivation and powder granulation, and then three-dimensional composite biological organic fertilizer with organic, inorganic and microbial active constituents is obtained. Mushroom compost and pig manure are used as accessories which are easily obtained and degraded, the stacker fermentation time is short, only one time of fermentation is needed, the C / N ratio can be effectively adjusted, and the water content of the sludge is reduced; and the efficient beneficial bio-fungus community CK21 is adopted. The microbial concentration is high, the secretion ability of the enzyme is strong, organic matters can be quickly decomposed so as to prevent the corruption of the organic matters, no odor exists, sludge is used for CK21 inoculation, fermentation starts fast, and the effect is good; and the product is inoculated with the CK21 fungus secondarily so as to further balance and activate nutrients, and the microbial natural reproduction is utilized to realize the is called flower dipping absorbing of the plants to nutrients. The invention has the advantages of optimizing the composting conditions, shortening the composting time, reducing energy consumption of turning, and reducing the damage of the heavy metal on the ecological environment.

Owner:厦门市政环境科技股份有限公司

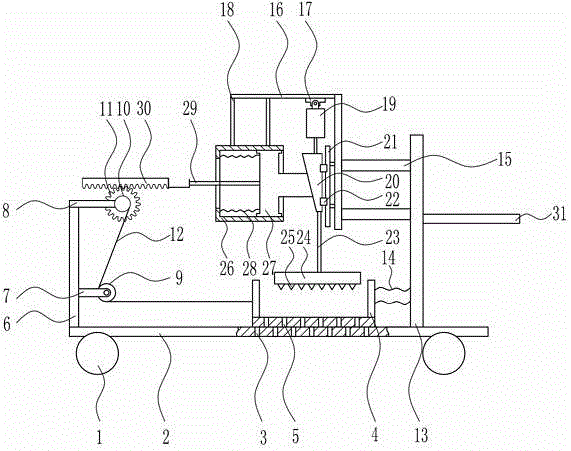

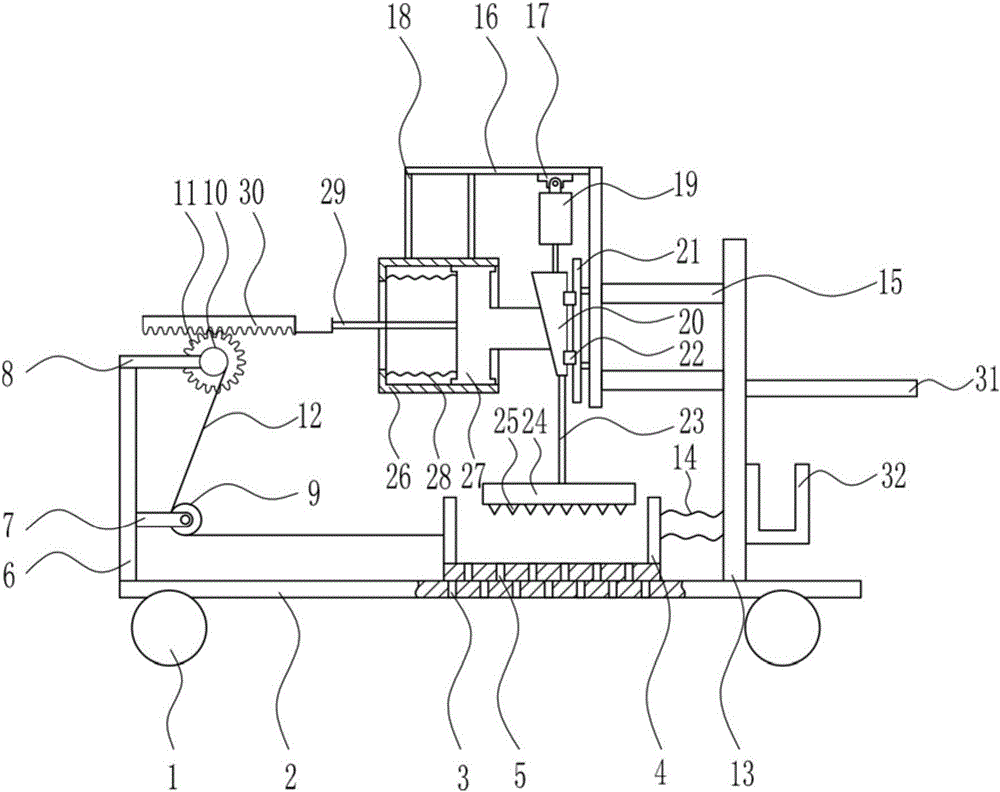

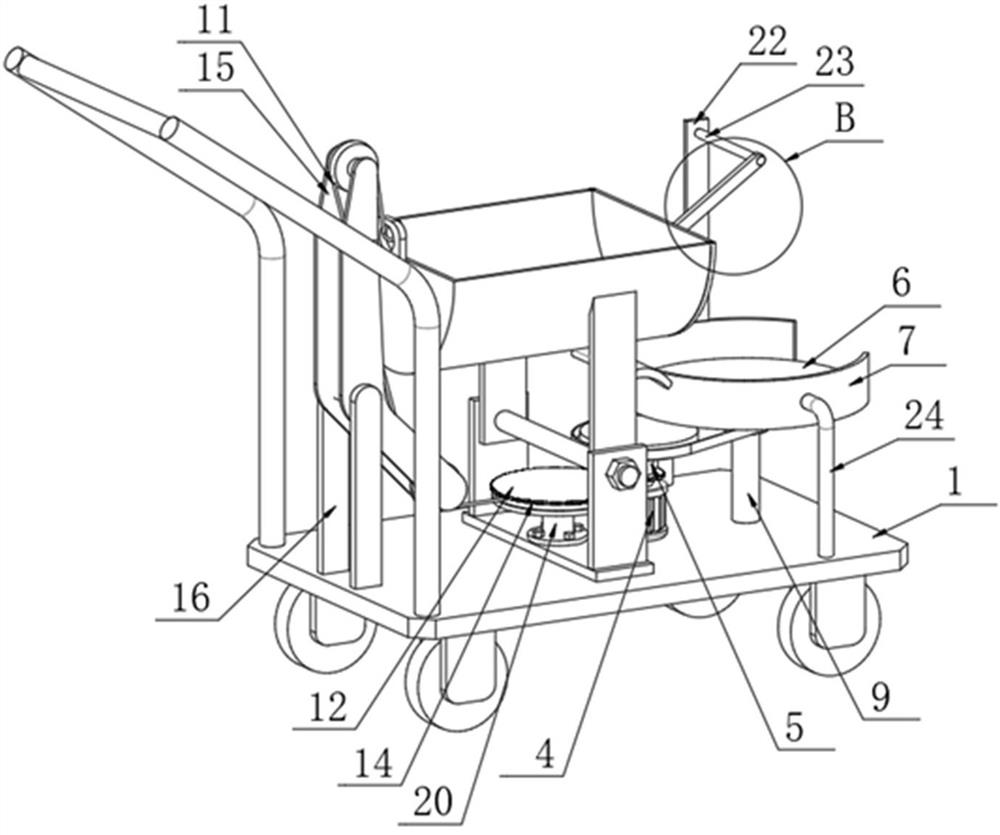

Efficient solid fertilizer spreading device for agricultural industry

ActiveCN106258133AGood throwing effectNovel structureFertiliser distributersFixed frameAgricultural engineering

The invention relates to a solid fertilizer spreading device, in particular to an efficient solid fertilizer spreading device for agricultural industry. The invention provides the efficient solid fertilizer spreading device for agricultural industry with the advantages of good spreading effect, novel structure and high work efficiency. In order to solve the technical problems, the invention provides the efficient solid fertilizer spreading device for agricultural industry, and the efficient solid fertilizer spreading device comprises wheels, a bottom plate, a fertilizer box, a left frame, a first fixing frame, a second fixing frame, a fixed pulley, a wire winding wheel, gears, a pull wire, a right frame, a first spring, a first installing seat, a top plate, a second installing seat, a third installing seat, an air cylinder, a trapezoidal block, a first slide rail, a first slide block, a first ascending and descending rod, a press block, roller compaction teeth, a second slide rail, a second slide block, a second spring, a moving rod, a rack and a push hand, wherein the bottom plate is arranged at the top of the two wheels. The efficient solid fertilizer spreading device achieves the effects that the spreading effect is good; the structure is novel; the work efficiency is high.

Owner:佛山市嘉沃农业科技合伙企业(有限合伙)

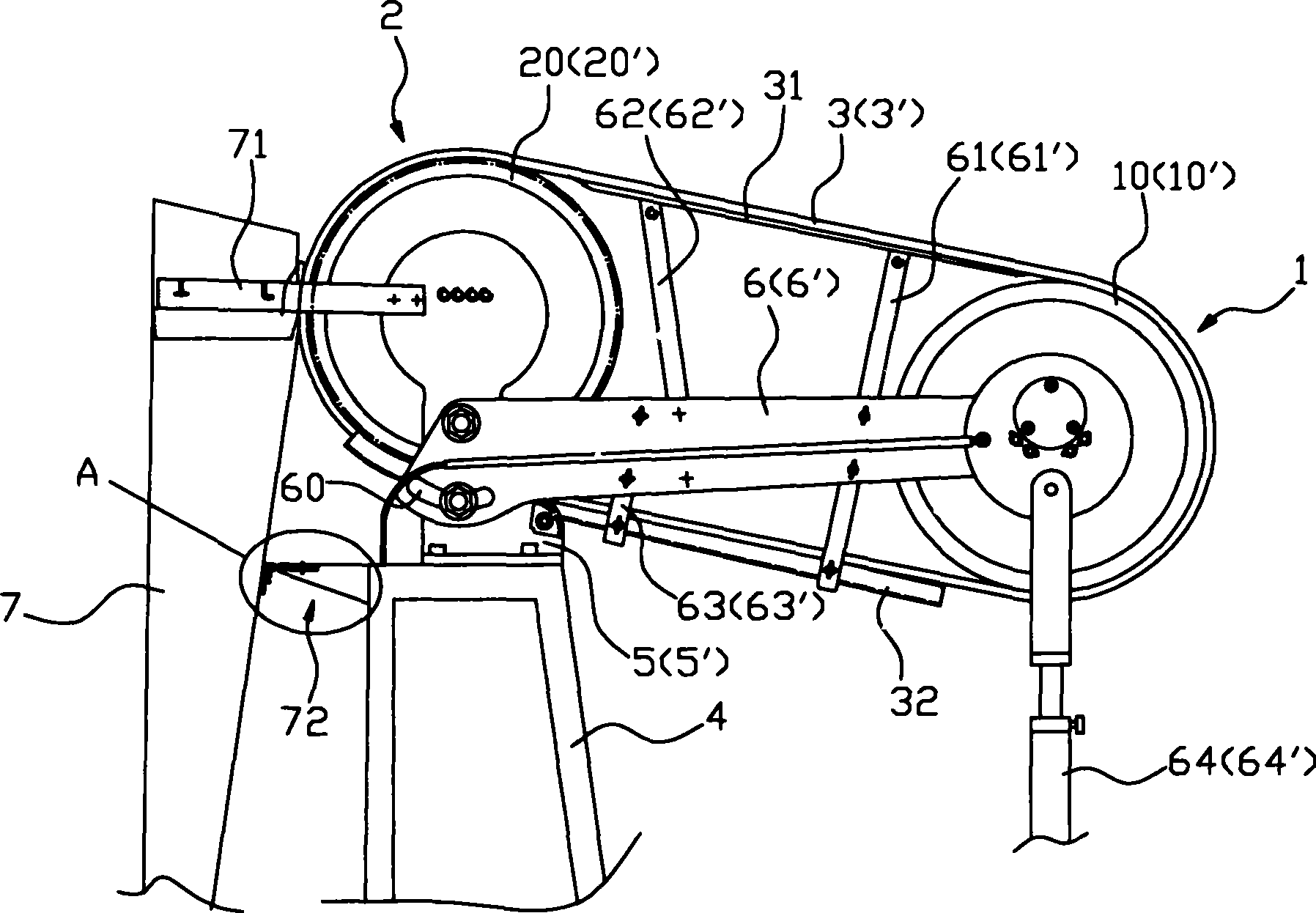

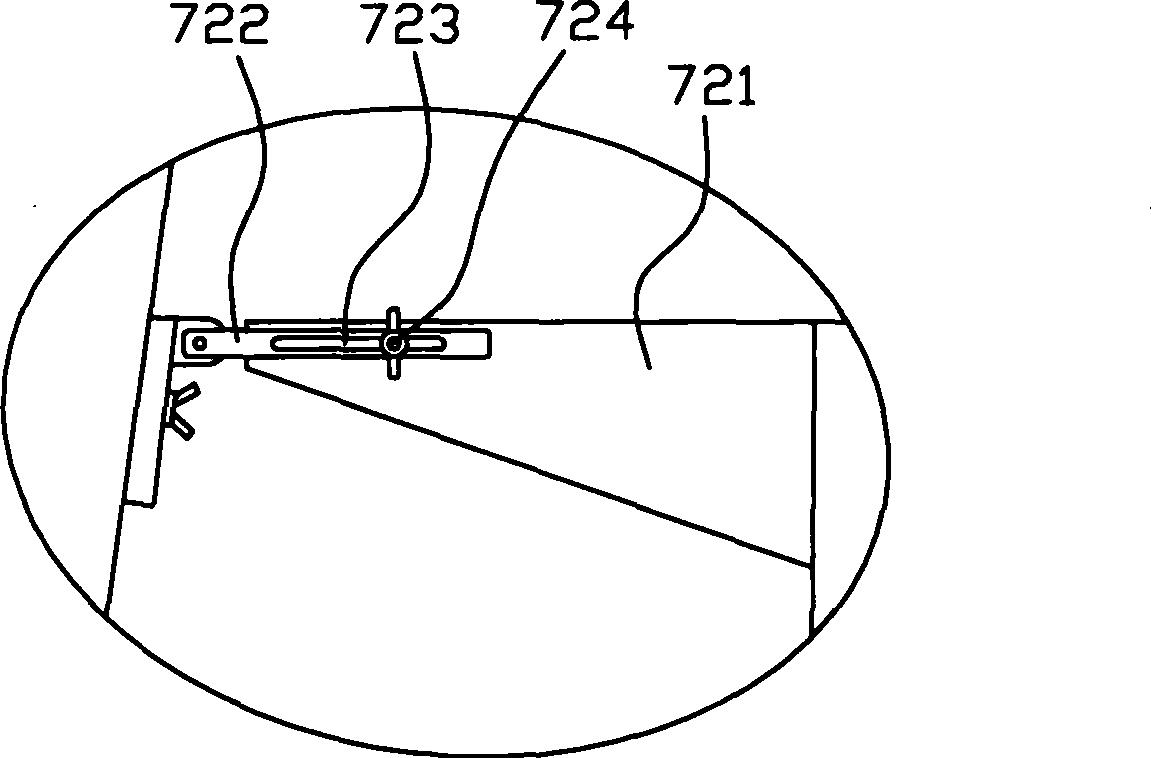

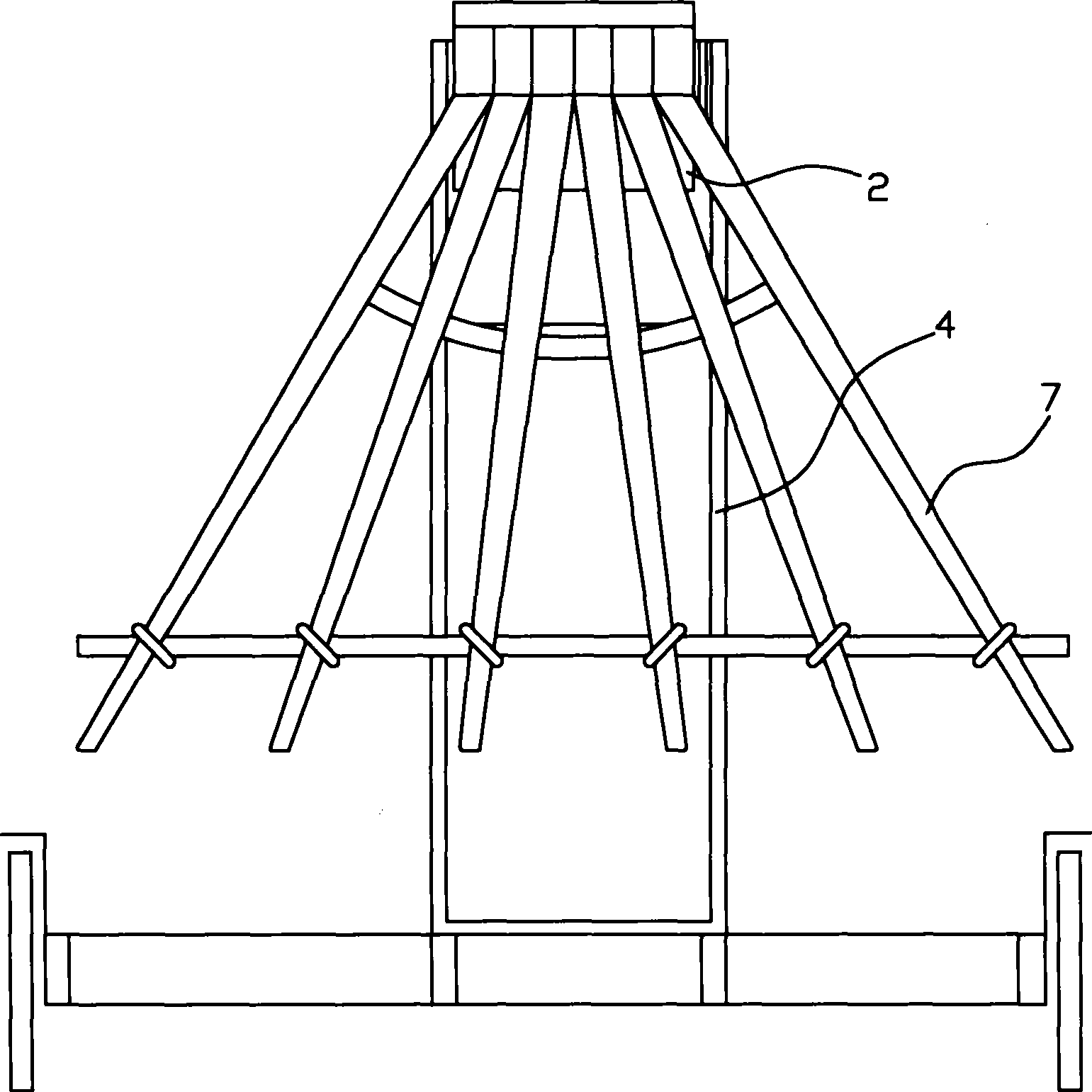

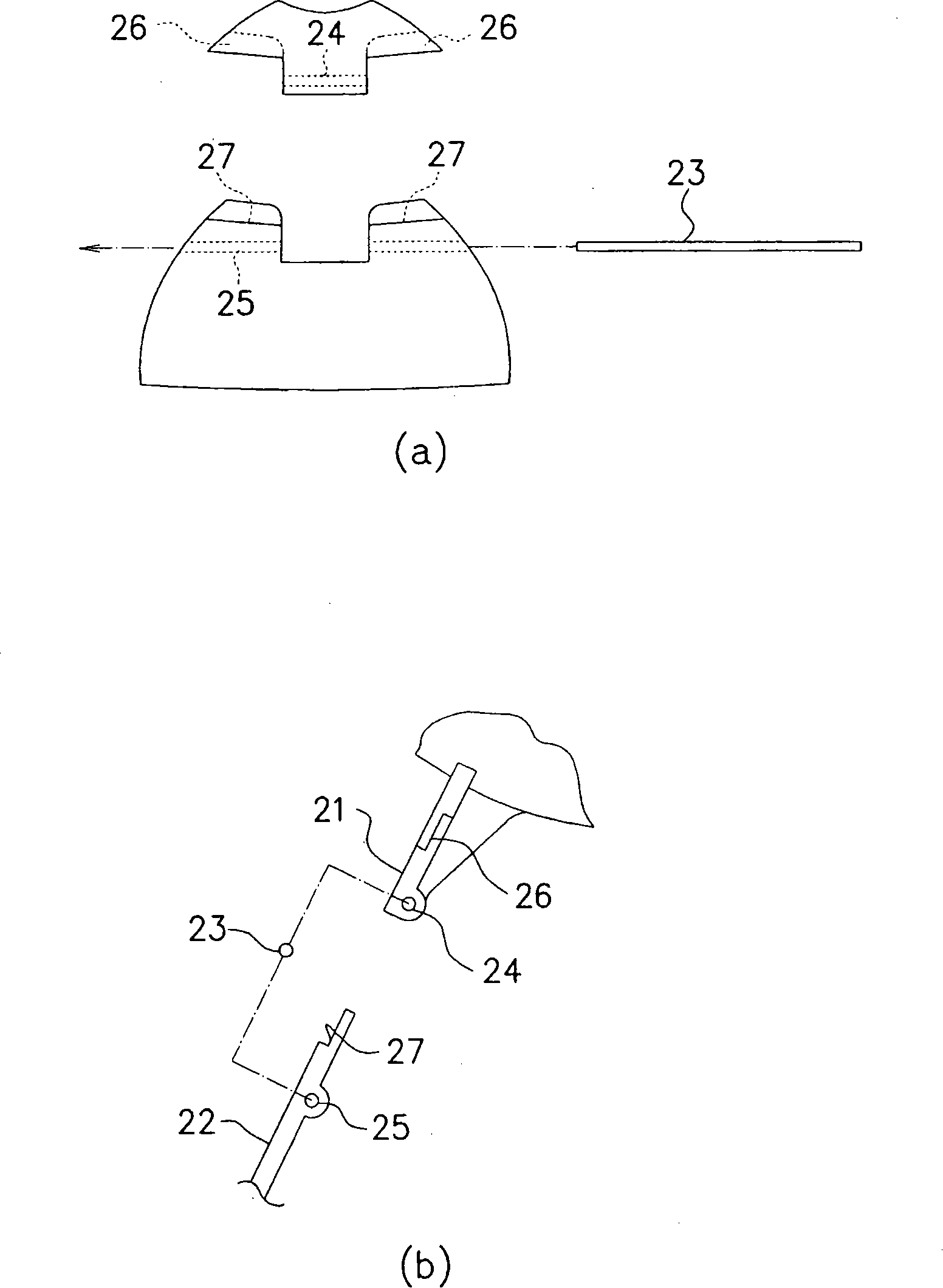

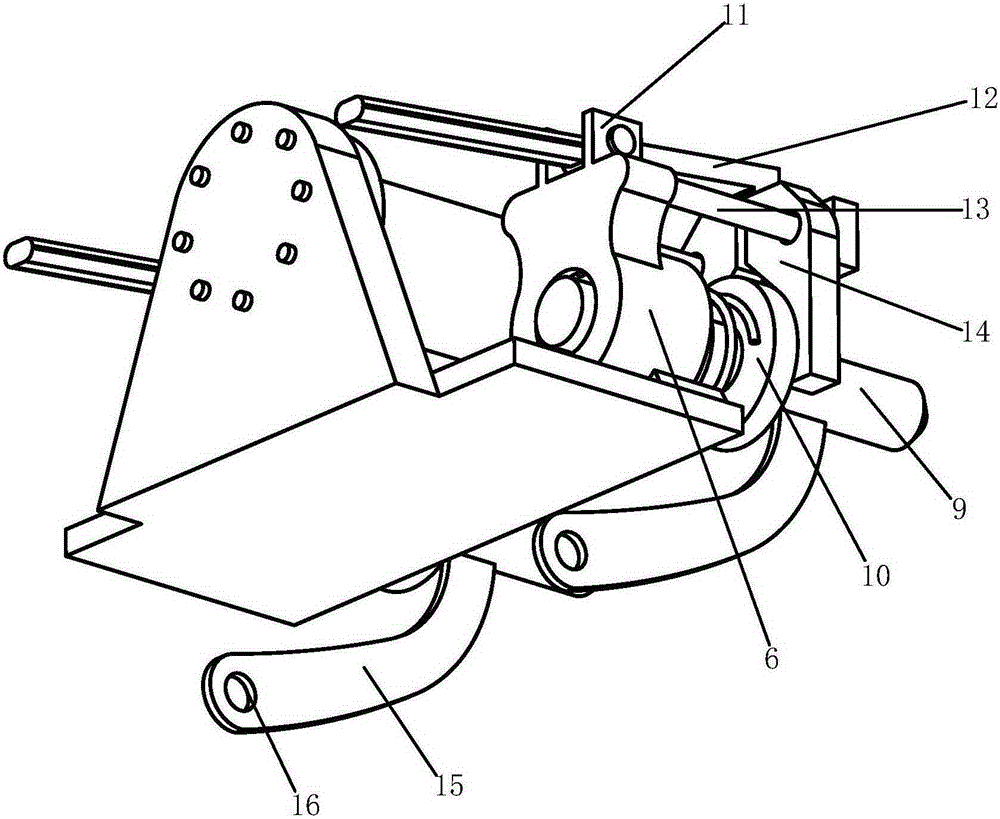

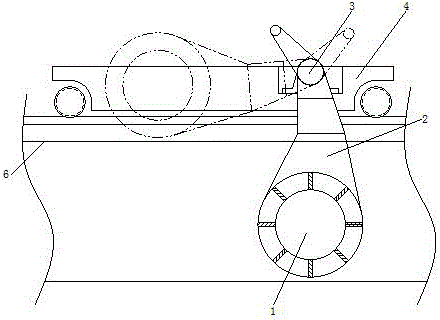

Rice bowl seedlings cast-seedling device

InactiveCN101455145ASimple structureGood throwing effectTransplantingDrive wheelReciprocating motion

A paddy rice pot seedling throwing machine includes a driving wheel comprising a first left synchronizing wheel and a first right synchronizing wheel which rotate synchronously, wherein, inside of one of the wheels is provided with a stepper motor for driving the wheel to rotate; a driven wheel comprising a second left synchronizing wheel and a second right synchronizing wheel which rotate synchronously, and a frontward seedling-pulling head and a cylinder for driving the seedling-pulling head to perform reciprocating motions; the first left synchronizing wheel and the first right synchronizing wheel, the second left synchronizing wheel and the second right synchronizing wheel being connected through a left synchronous belt and a right synchronous belt respectively; a seedling disk, of which the left and right ends are respectively positioned on the left synchronous belt and the right synchronous belt, earthen bowl grooves being arranged in the left and right directions on the seedling disk, a seedling-pulling corresponding to the seedling-pulling head being provided on the bottom of the earthen bowl groove; a seedling-guiding tube positioned below the front side of the driven wheel. The present invention has advantages of simple transmission structure, low fault rate, convenient use and the like.

Owner:张国梁

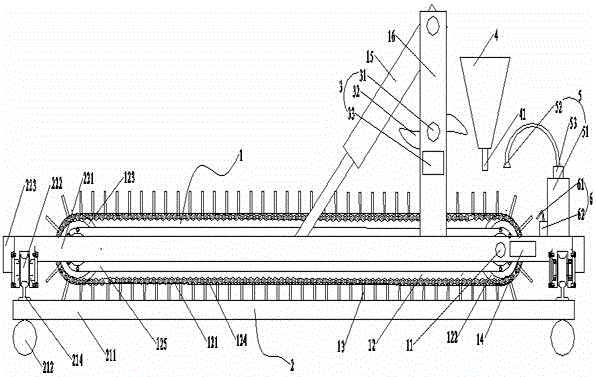

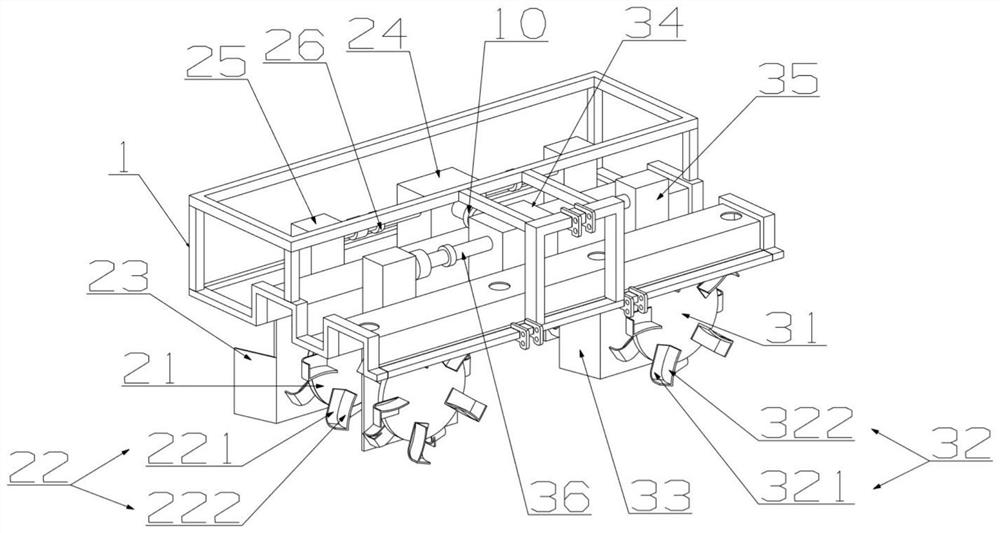

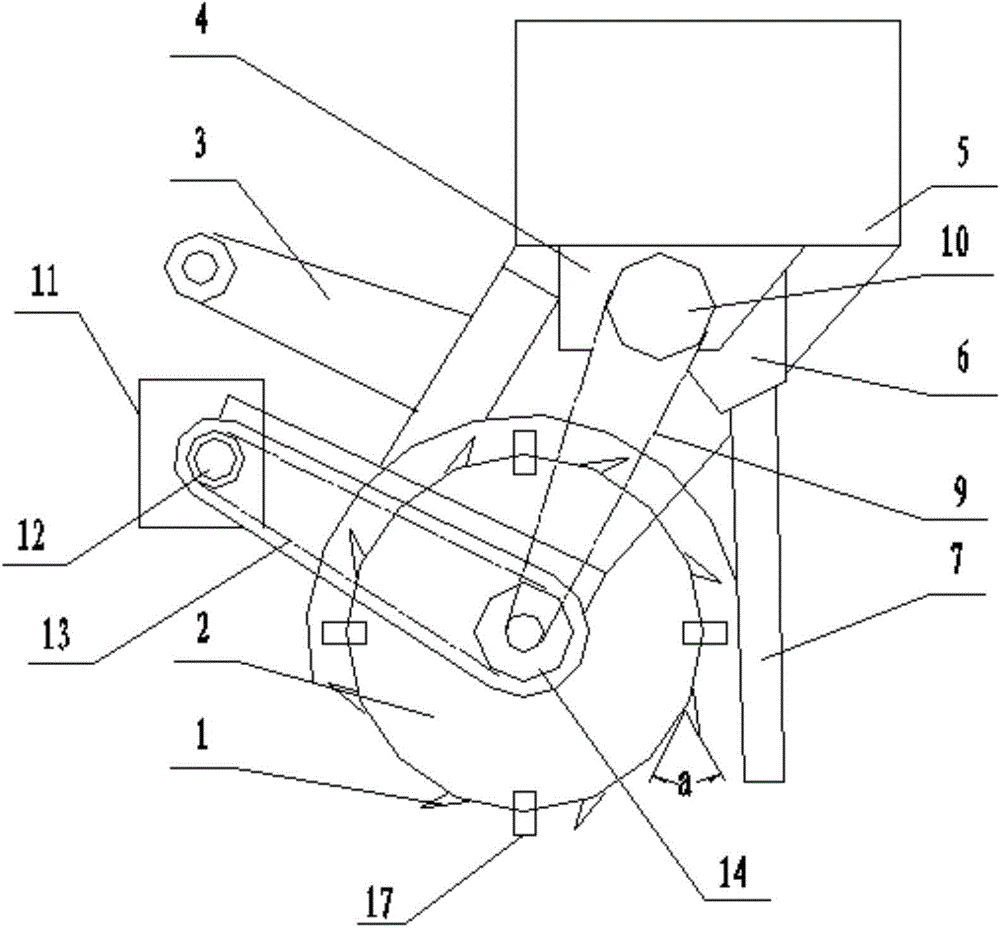

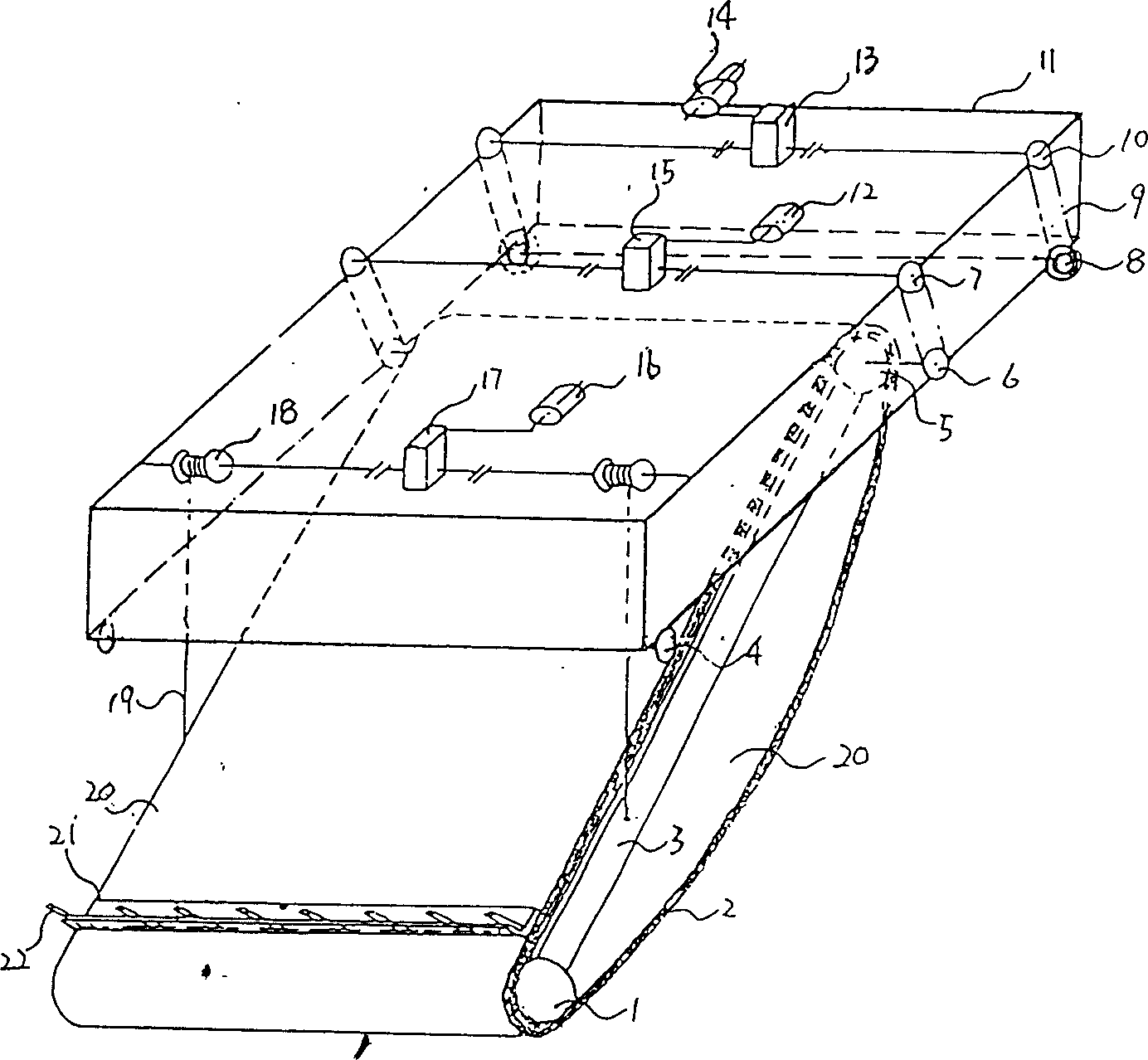

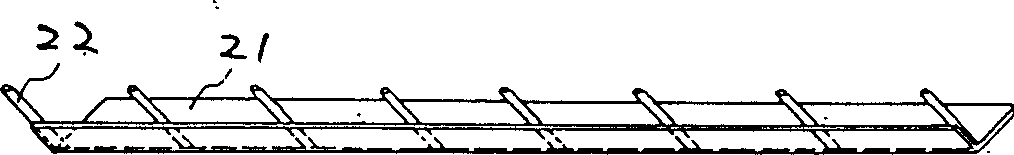

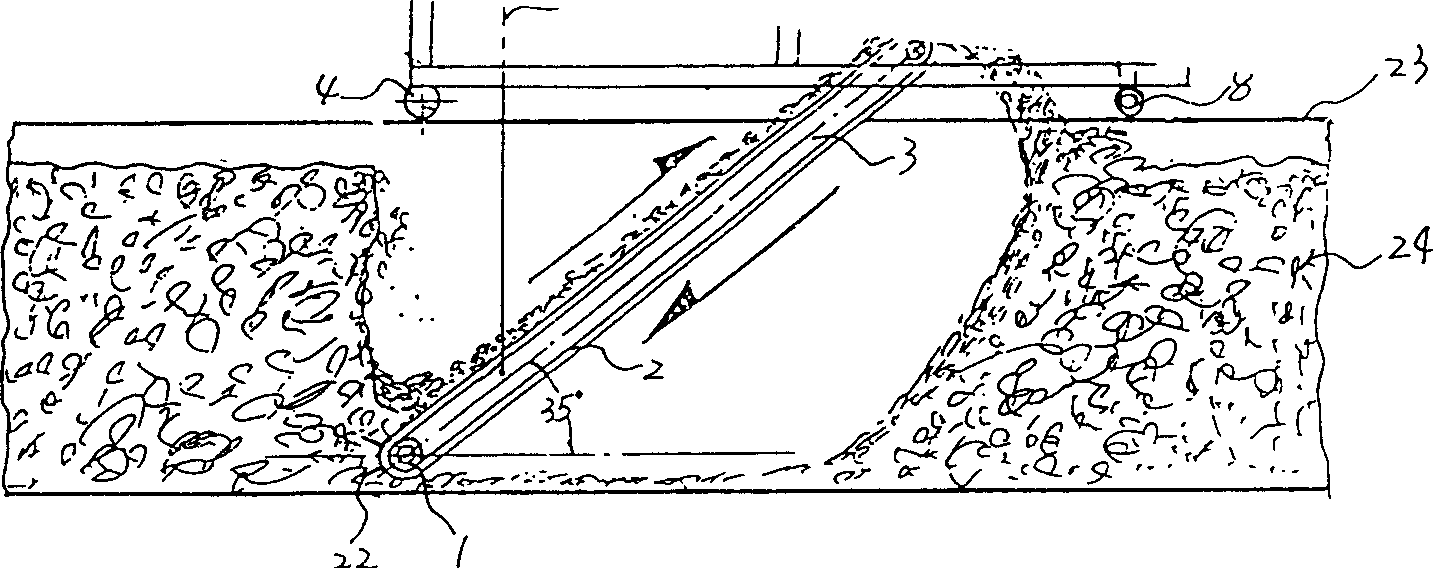

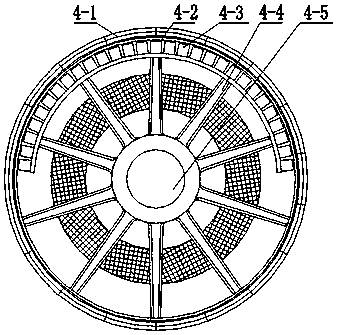

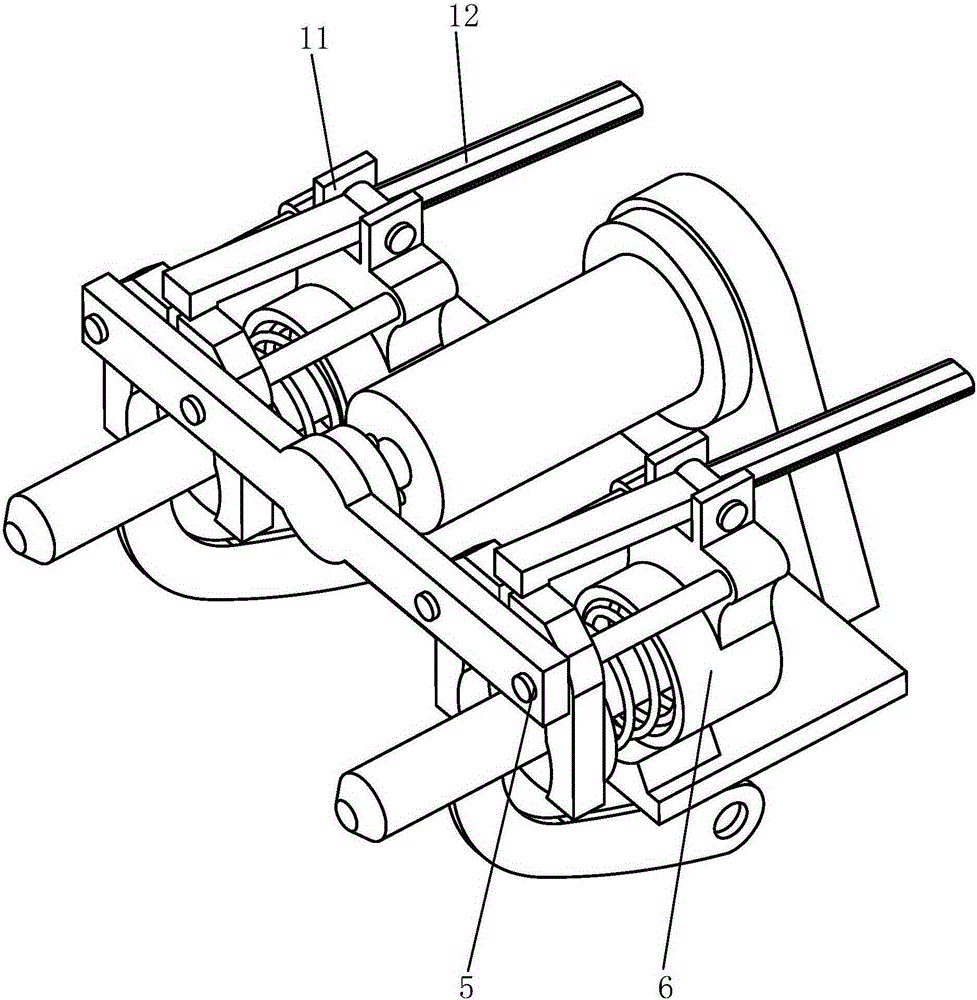

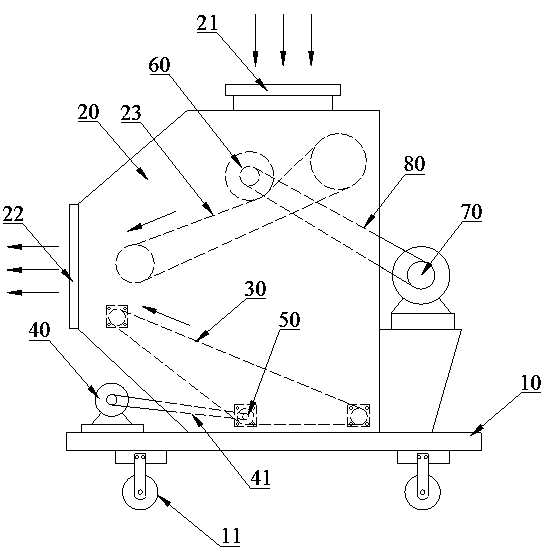

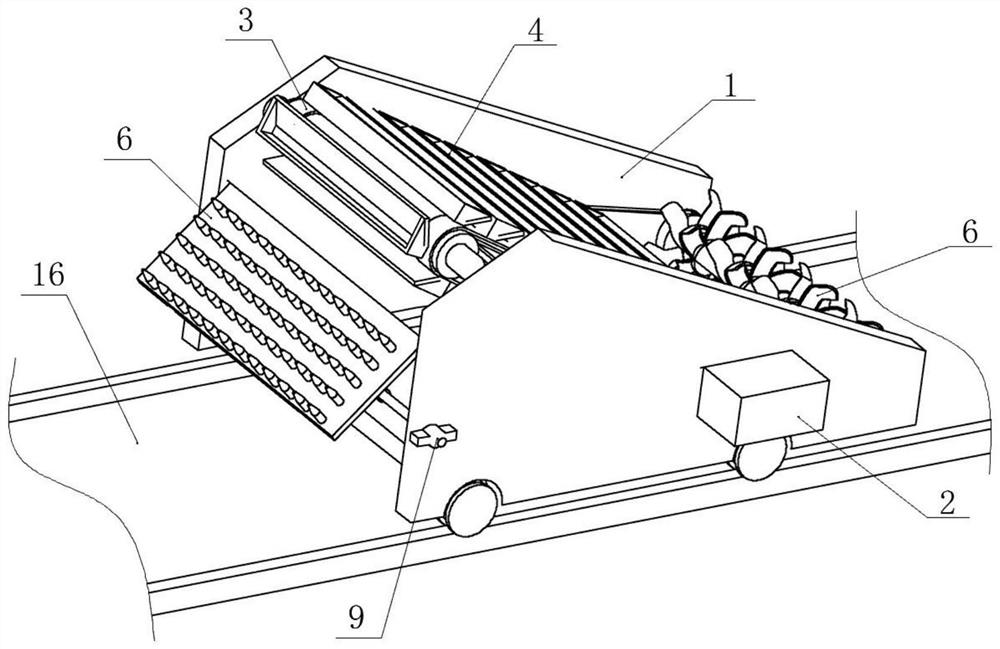

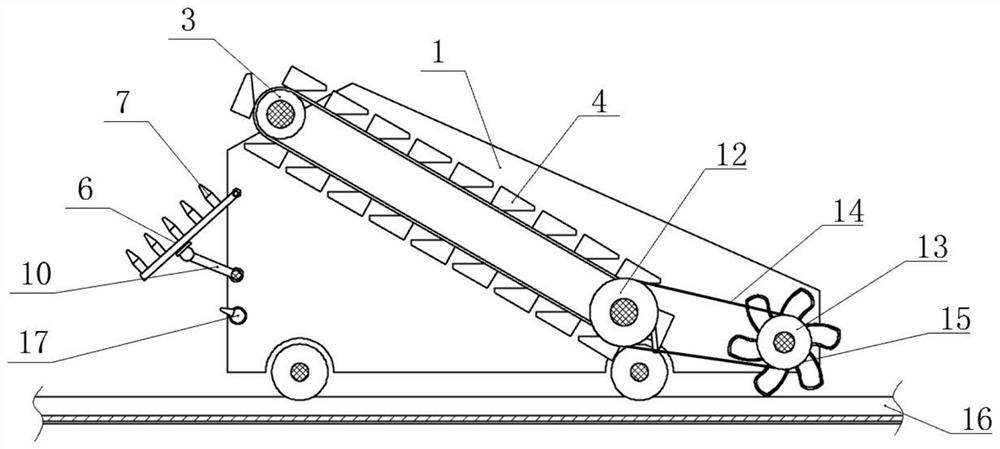

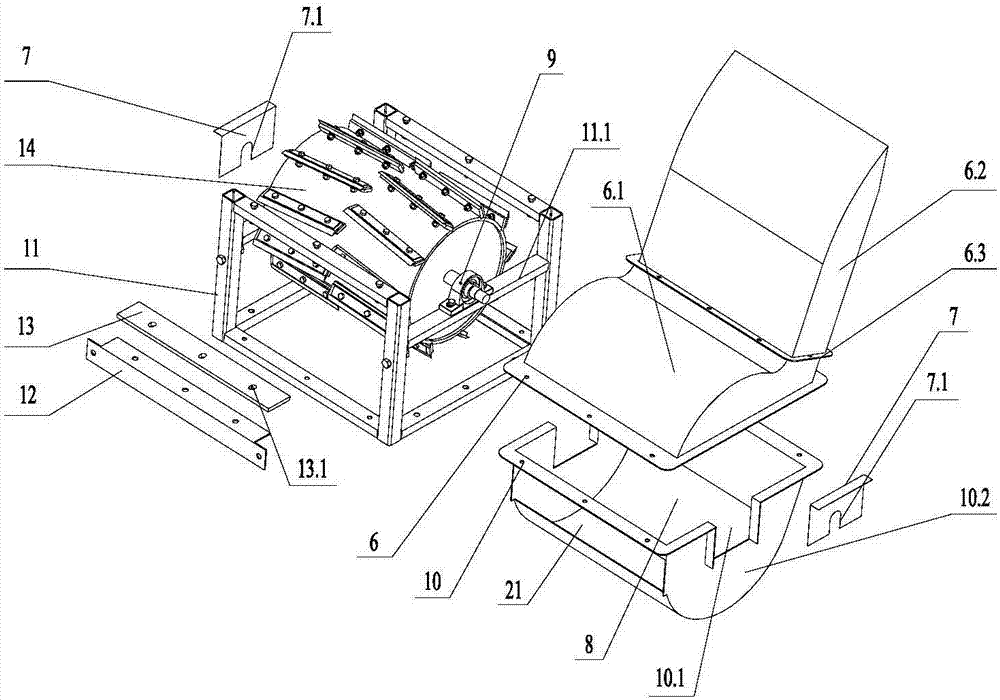

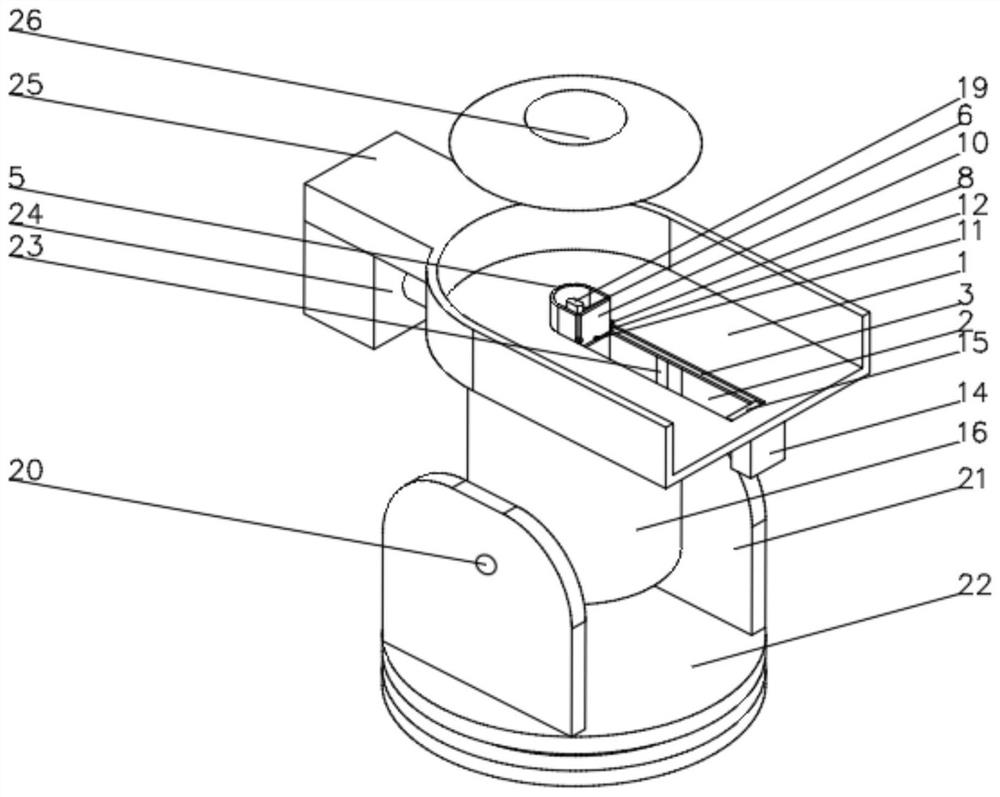

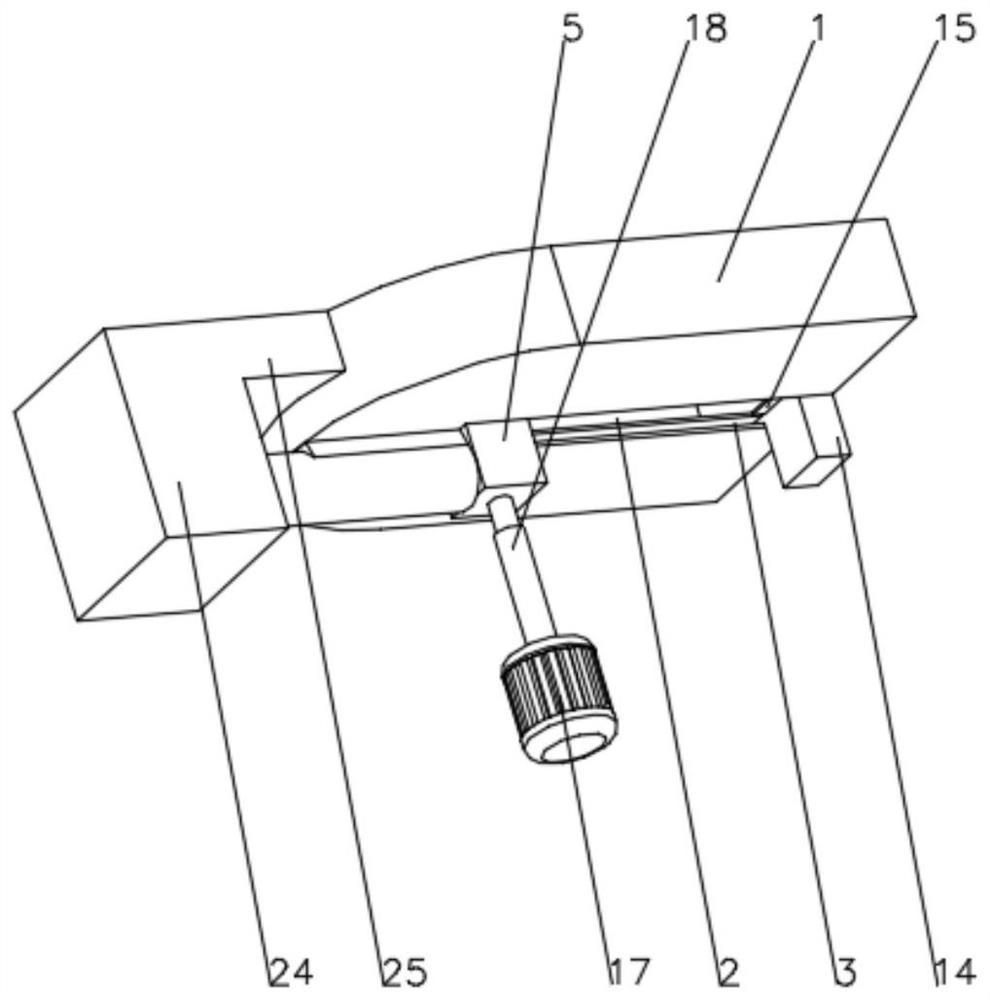

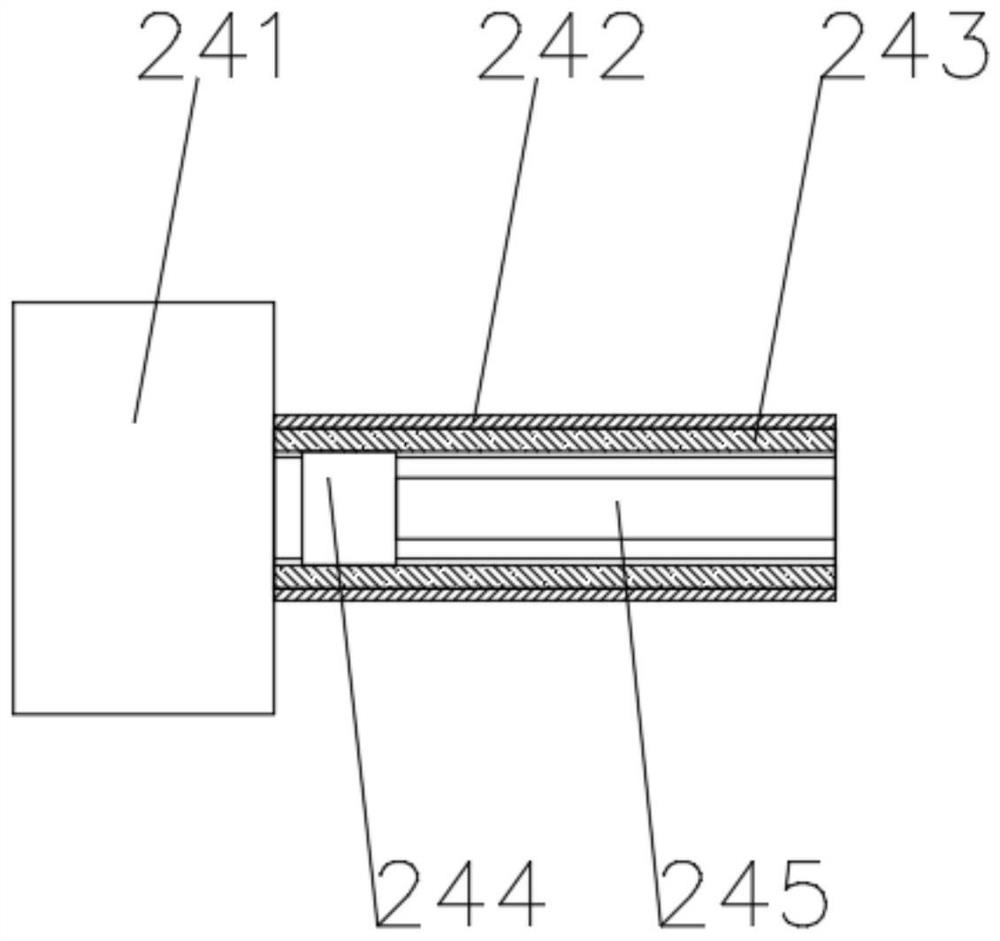

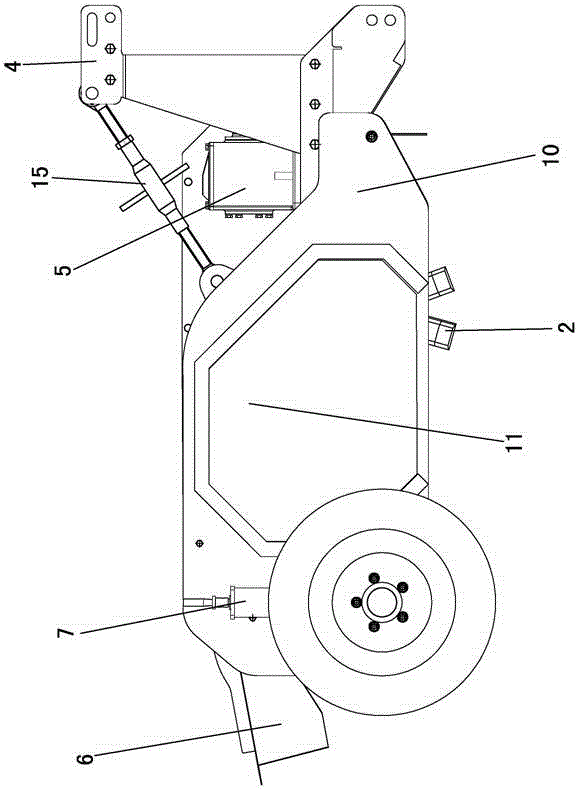

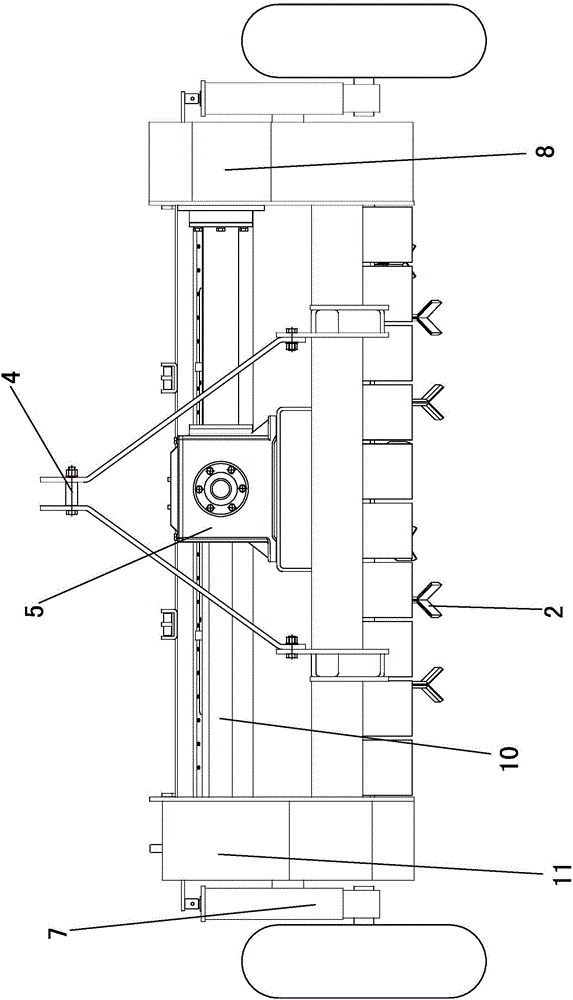

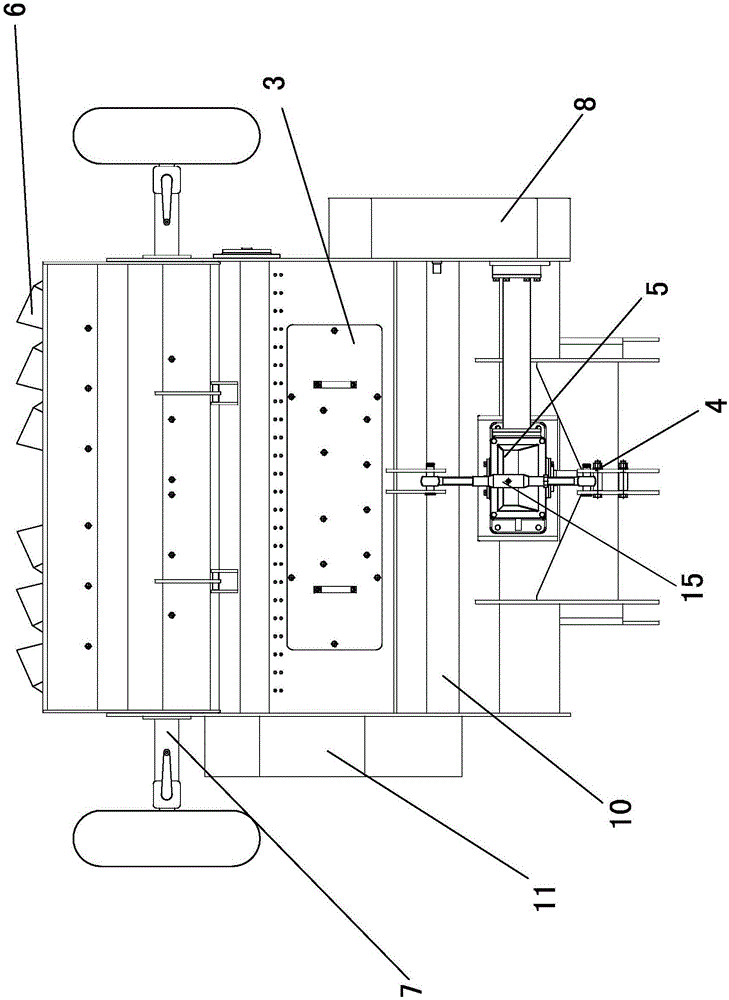

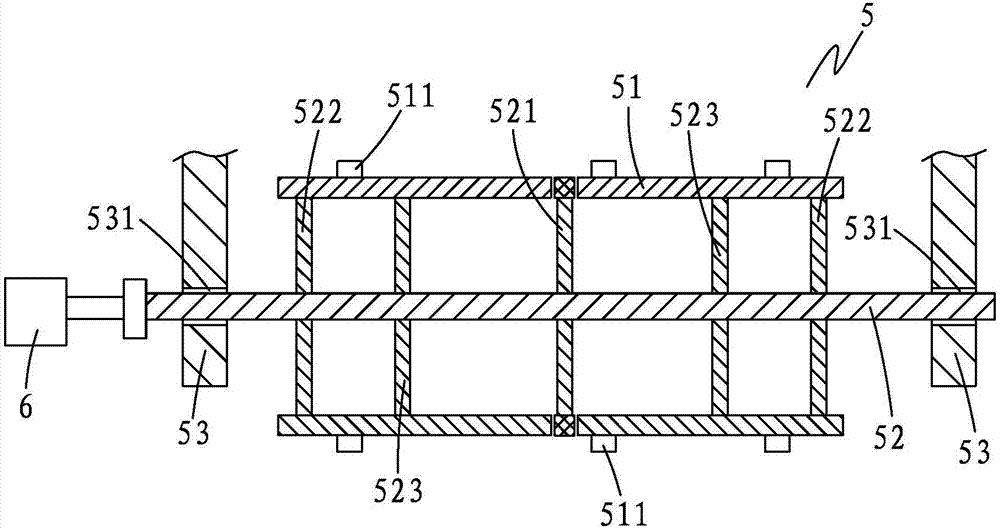

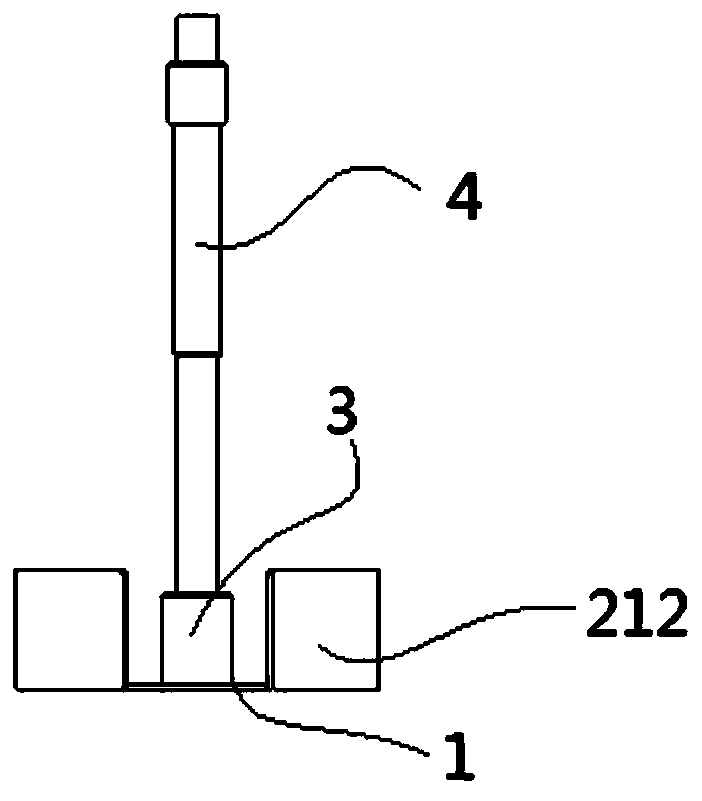

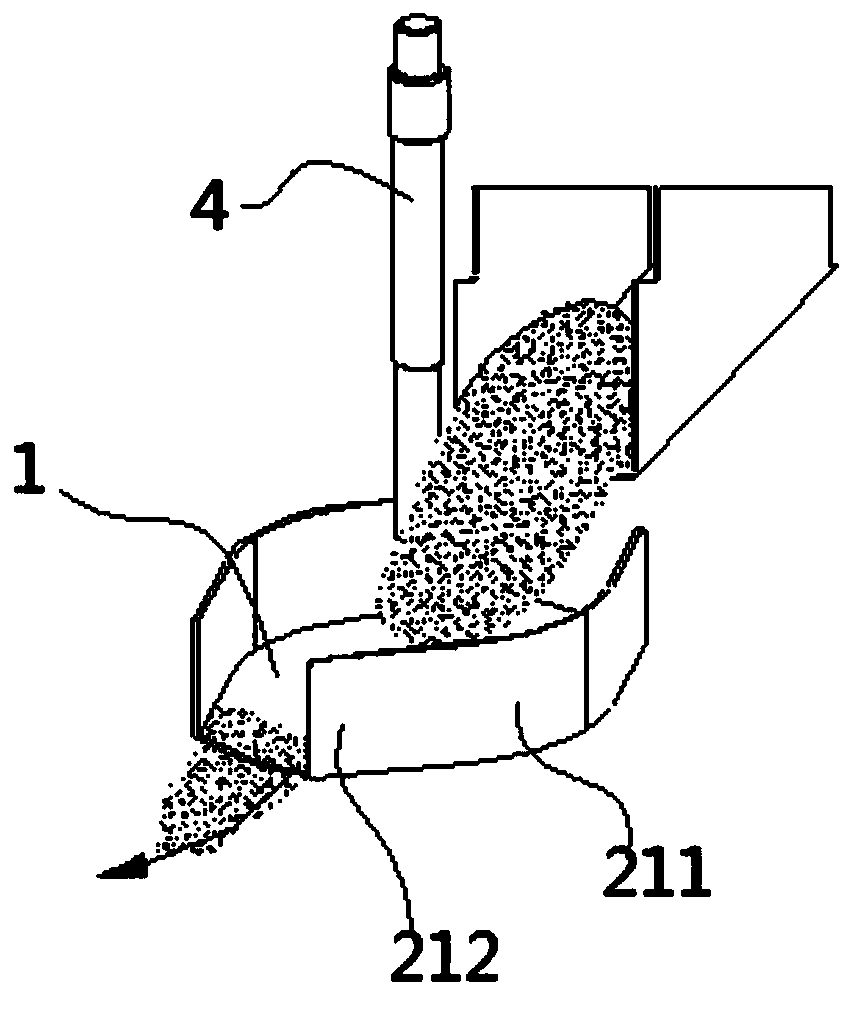

Movable turning-throwing machine

InactiveCN105753530ARealize all-round flippingGood throwing effectBio-organic fraction processingOrganic fertiliser preparationMechanical engineeringEngineering

The invention discloses a movable turning-throwing machine.The movable turning-throwing machine comprises a turning-throwing mechanism and a traveling mechanism.The traveling mechanism comprises a first traveling mechanism and a second traveling mechanism, and the second traveling mechanism is movably connected to the first traveling mechanism.The turning-throwing mechanism comprises a fixed shaft, a chain-plate conveyor, a plurality of turning-throwing plates, a turning-throwing power portion and a driving cylinder, wherein the fixed shaft is fixedly arranged on the second traveling mechanism; one end of the chain-slat conveyor is rotatably connected with the fixed shaft; the turning-throwing plates are fixedly arranged on a chain plate of the chain-plate conveyor and perpendicularly positioned on the chain plate along the length direction of the chain plate; the turning-throwing power portion drives the chain-plate conveyor to rotate; the driving cylinder is connected to the middle of the chain-plate conveyor.Transverse traveling and longitudinal traveling of the turning-throwing mechanism are realized by the aid of the first traveling mechanism and the second traveling mechanism respectively so as to further realize comprehensive turning and throwing of materials in a fermentation tank.By the turning-throwing plates on the chain plate of the chain-plate conveyor, one end of the chain-plate conveyor extends into the fermentation tank to turn up the materials, and the materials are then conveyed along with the turning-throwing plates and the chain plate to the other end and thrown out.The movable turning-throwing machine is excellent in turning-throwing effect and high in operation efficiency.

Owner:SHAYANG MARGIN FARM MACHINERY CO LTD

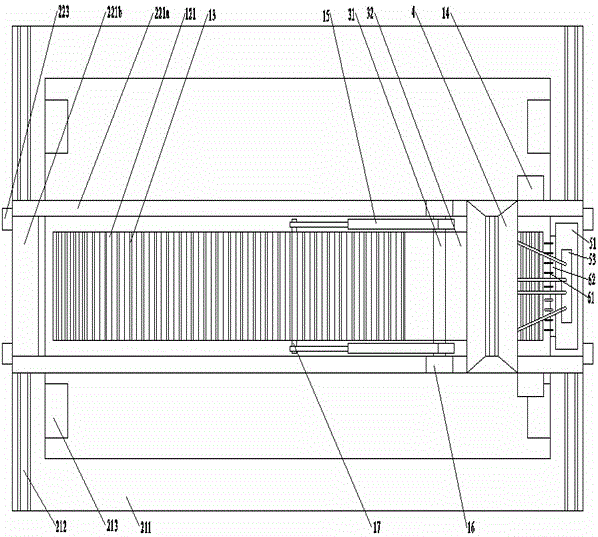

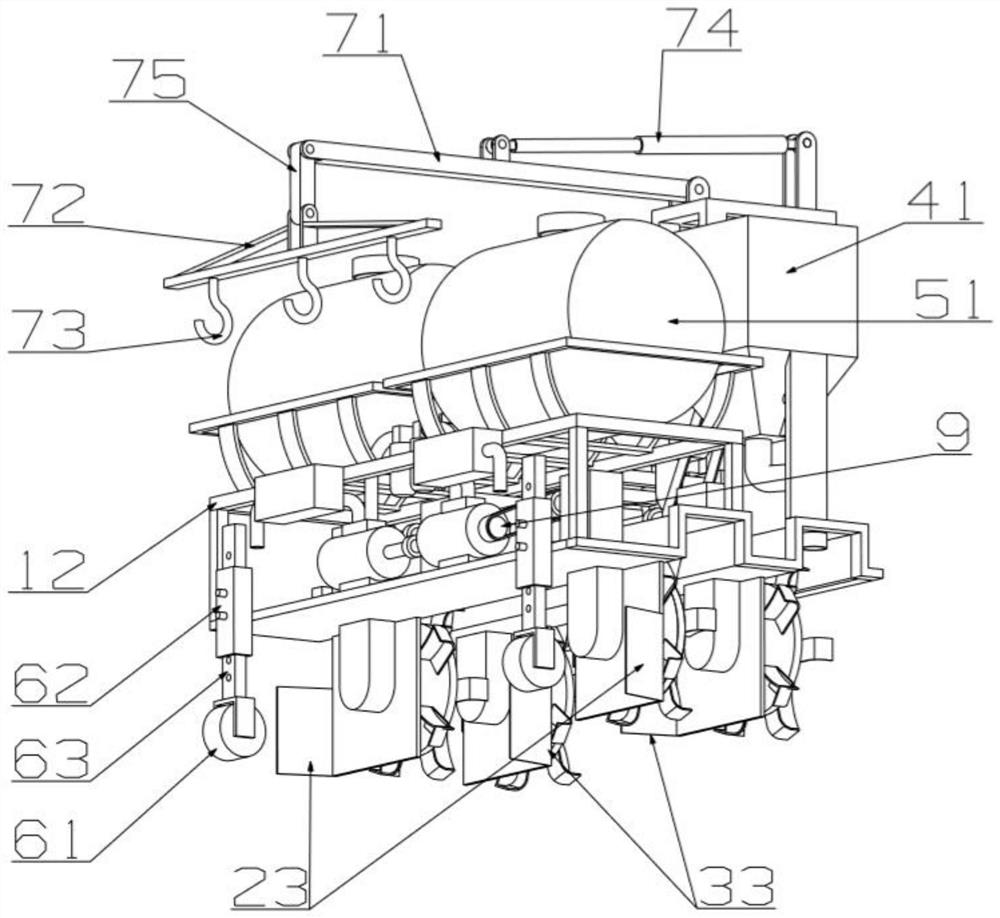

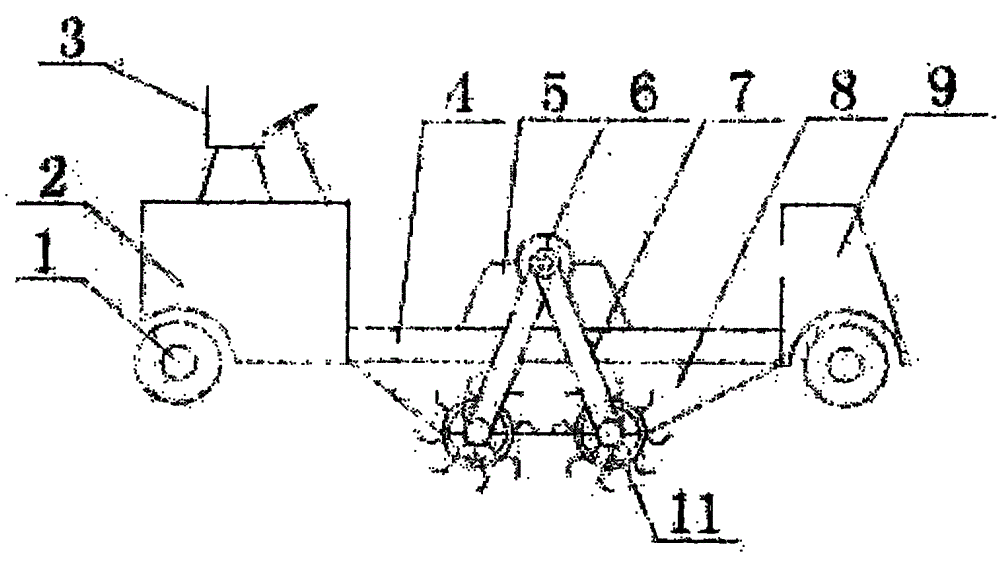

Transverse soil throwing type sugarcane row-crossing hilling fertilization management machine

InactiveCN112470580AImprove soil cultivation efficiencyAvoid formingSpadesPloughsAgricultural engineeringMechanical engineering

The invention relates to the field of sugarcane planting machinery, and particularly discloses a transverse soil throwing type sugarcane row-crossing hilling fertilization management machine. The machine comprises a rack, a first soil throwing device, a second soil throwing device, a fertilization device, a liquid application device, a hoisting device and a fixed depth whee group, and the first soil throwing device and the second soil throwing device are arranged on the two sides of the rack respectively. By increasing the width of the rack and arranging soil throwing discs on the two sides ofthe rack, three rows of sugarcanes can be hilled up in a row-crossing mode at the same time, and the hilling efficiency is improved; the soil throwing direction of the soil throwing discs is perpendicular to the advancing direction of the equipment, a large amount of broken soil can be thrown to sugarcane rows through throwing and digging cutters, the edges of hilling rows are trimmed through inclined faces of soil baffles, and intermittent pits are prevented from occurring in the soil; the bottom of a fertilization box drives impeller groups through a rotating rod and is matched with the inverted-cone-shaped inclined surface to make fertilization smoother; the fertilizer feeding efficiency is higher and safer through the hoisting device; and by means of a rigid transmission system composed of a gear box and a connecting shaft, the soil throwing devices are better in rigidity and higher in reliability.

Owner:GUANGXI ZHUANG AUTONOMOUS REGION ACAD OF AGRI SCI

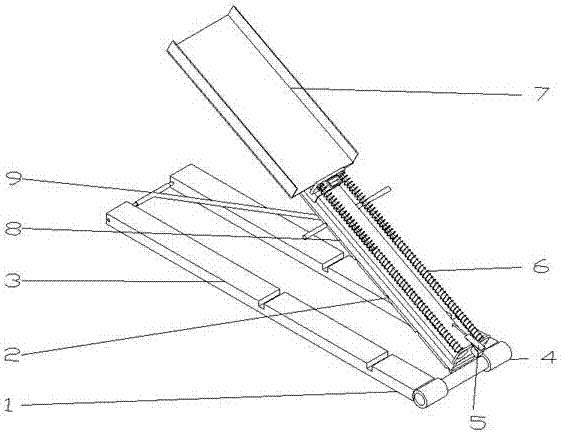

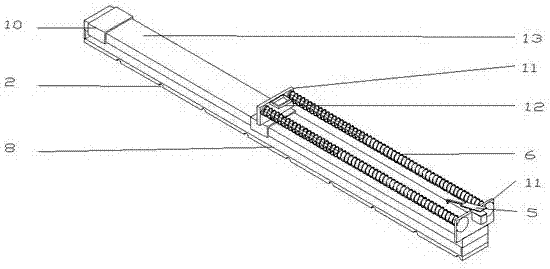

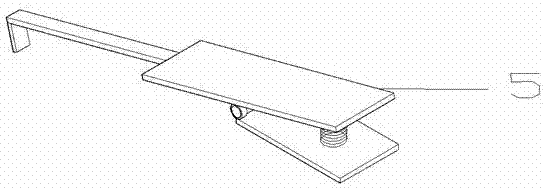

Flinger for unmanned aerial vehicle

InactiveCN107097969AEasy storage and transferChange throwing angleLaunching/towing gearEngineeringFastener

The invention relates to a flinger for an unmanned aerial vehicle. The flinger comprises a sliding block, a blocking plate, a pull ring and a sliding rail, wherein five positioning holes are formed in the bottom of a supporting plate; and the pull ring is fixed to the back of the rear sliding block. According to the flinger for the unmanned aerial vehicle, a baseplate is arranged, and a supporting and positioning rod fixing groove is formed; a supporting and positioning rod can rotate by an angle to be placed in the supporting and positioning rod fixing groove, and the sliding rail rotates by an angle to be placed in a gap in the middle part of the baseplate, so that a flinger body is convenient to transfer and store; the sliding rail is a rotatable mechanism, and the magnitude of an included angle between the sliding rail and the baseplate can be freely adjusted by the sliding rail through a revolving pair mechanism, so that the flinging angle of the unmanned aerial vehicle is changed, and the using of the flinger body is more flexible; two springs are arranged, and the elasticity of the two springs is high, so that the flinging of the unmanned aerial vehicle is higher and farther, and the flinging effect is better; and an automatic resetting spring is arranged on a fastener, so that the fastener can be firmly arranged in the pull ring in a pushing manner, and the flinger body is more convenient to use.

Owner:BINZHOU UNIV

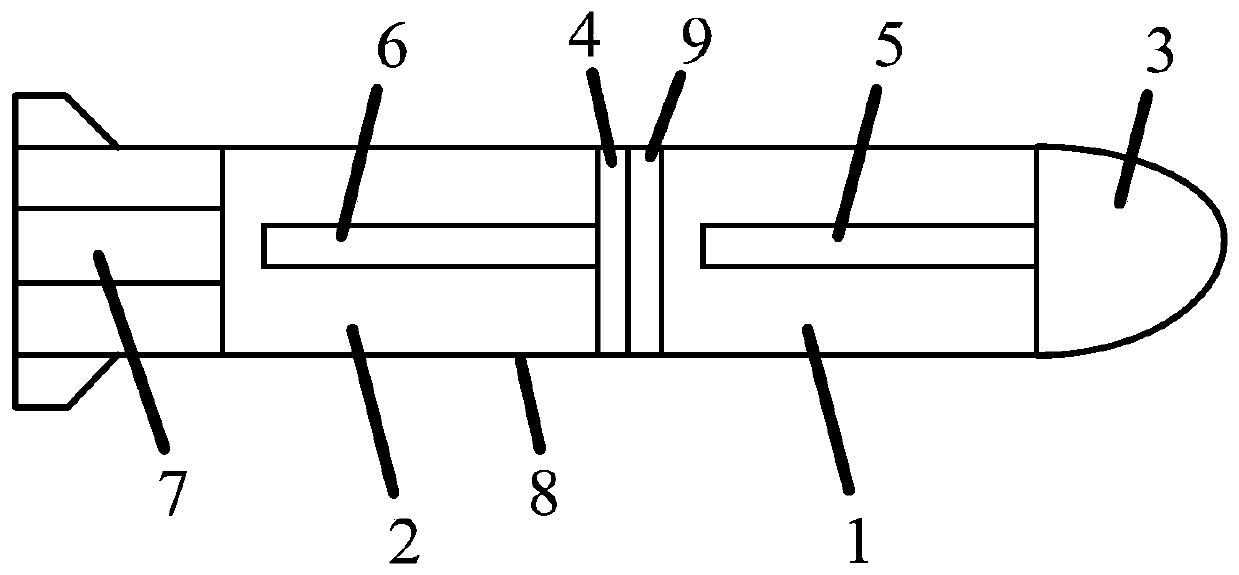

Composite fire extinguishing bomb and method of using same

PendingCN110947141AEffectively extinguishPrevent reburningFire rescueProcess engineeringIndustrial engineering

A composite fire extinguishing bomb and a method of using the same are disclosed. The composite fire extinguishing bomb includes: a first accommodating cavity used for accommodating a dry powder extinguishing agent; a second accommodating cavity used for accommodating a water-based extinguishing agent and isolated from the first accommodating cavity; and a control mechanism connected with first accommodating cavity and the second accommodating cavity, and configured to open the first and second accommodating cavities one after another to spray the extinguishing agent towards the fire. By beinginstructed to spray the dry powder extinguishing agent and the water-based extinguishing agent to the fire in sequence, the composite fire extinguishing bomb solves the problems that an existing extinguishing bomb has a poor extinguishing capability and cannot meet a high extinguishing requirement.

Owner:应急管理部消防产品合格评定中心 +1

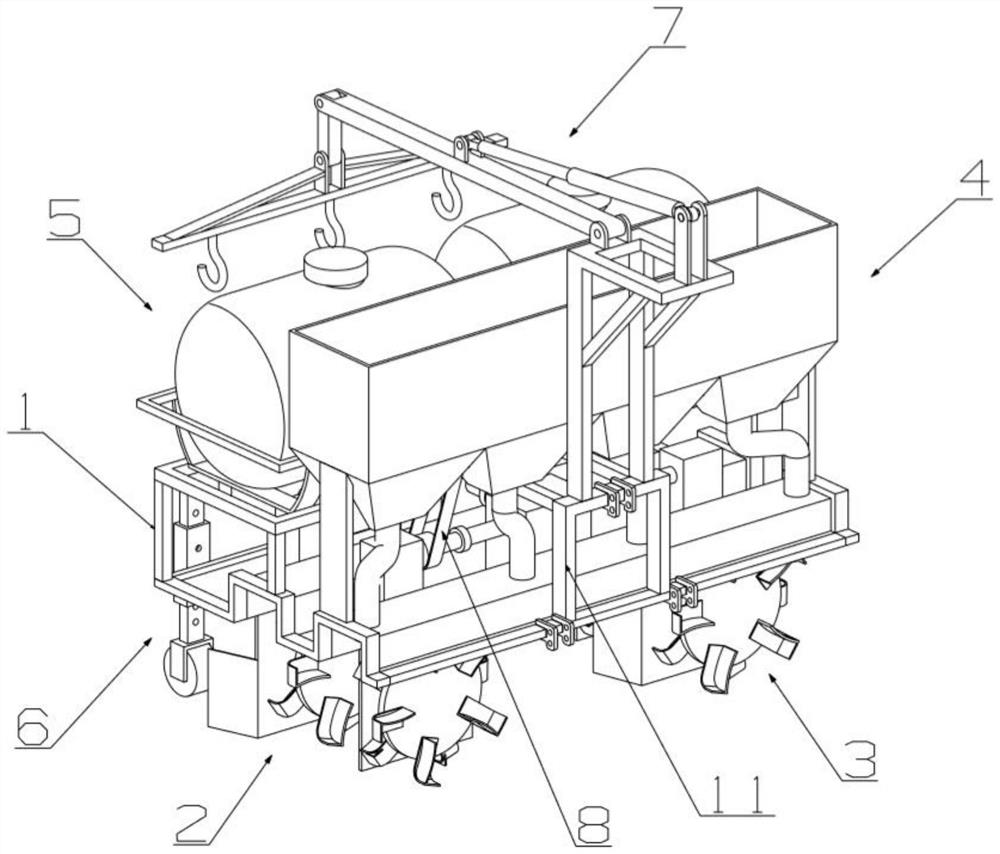

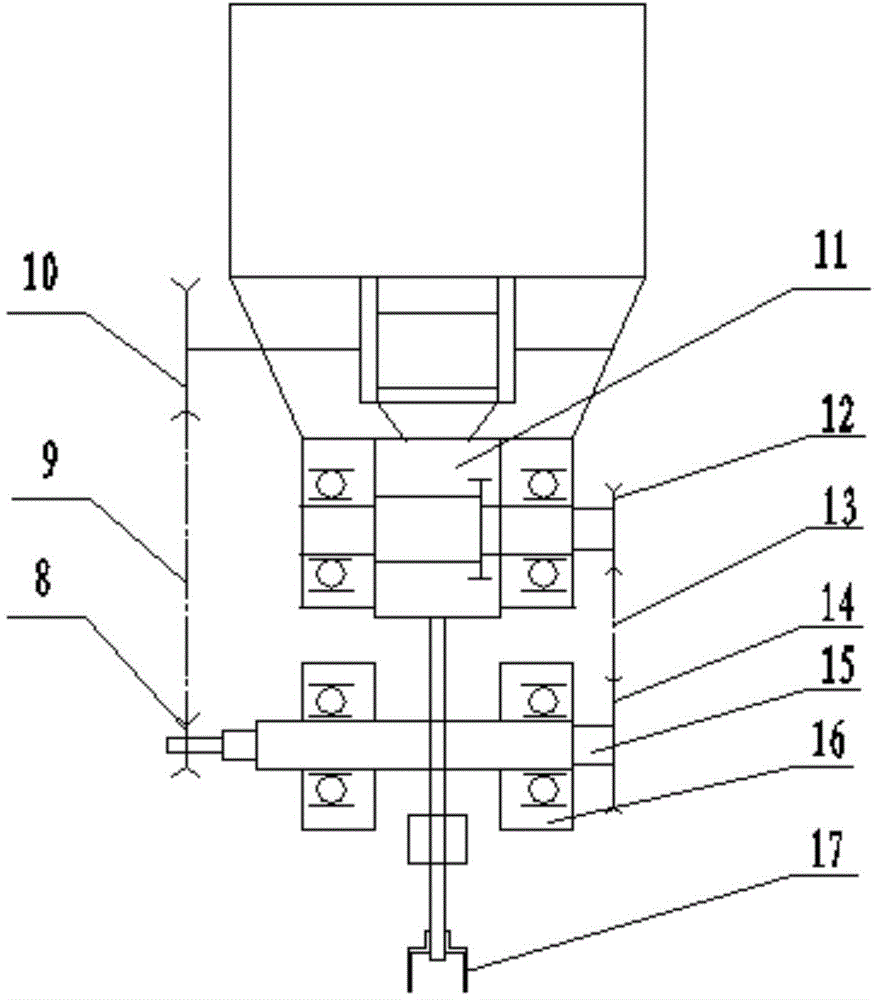

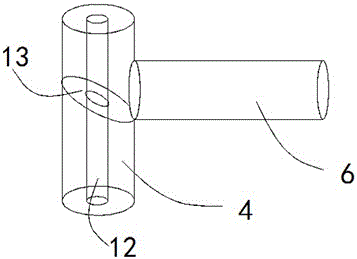

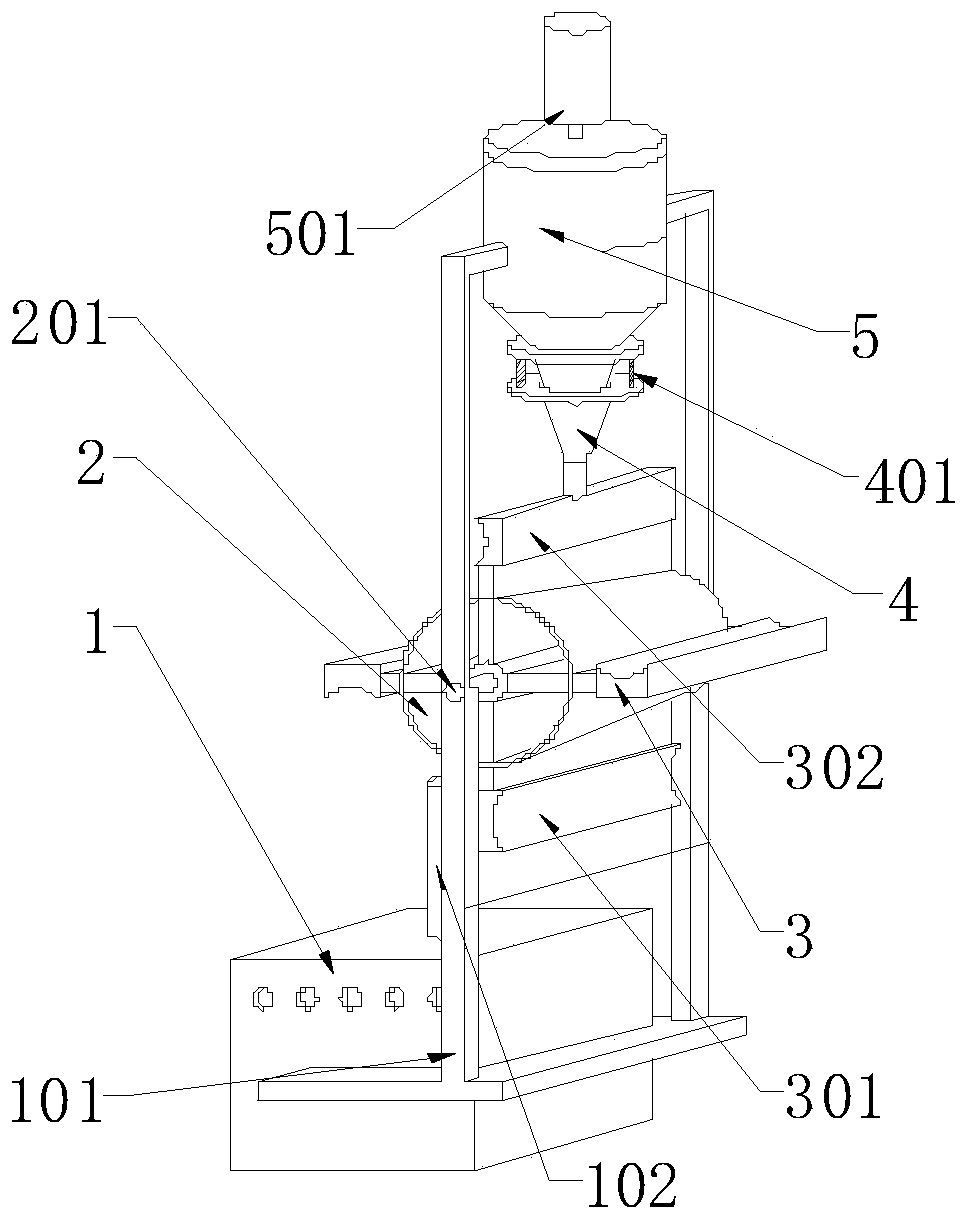

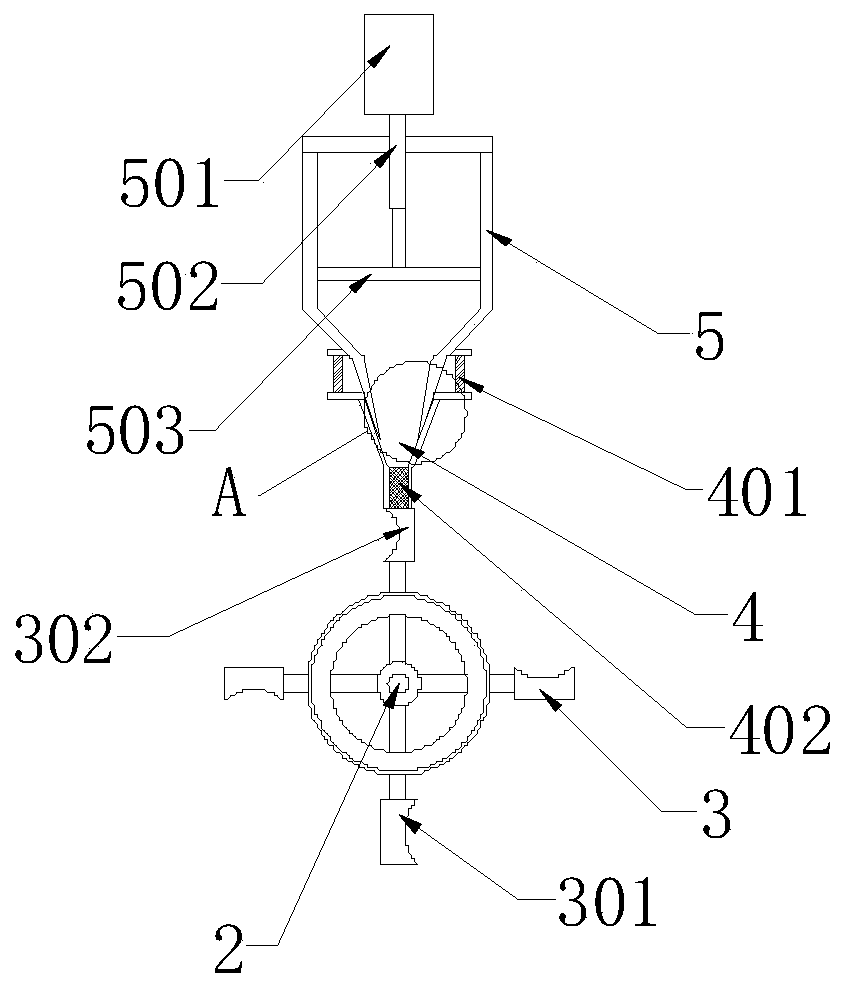

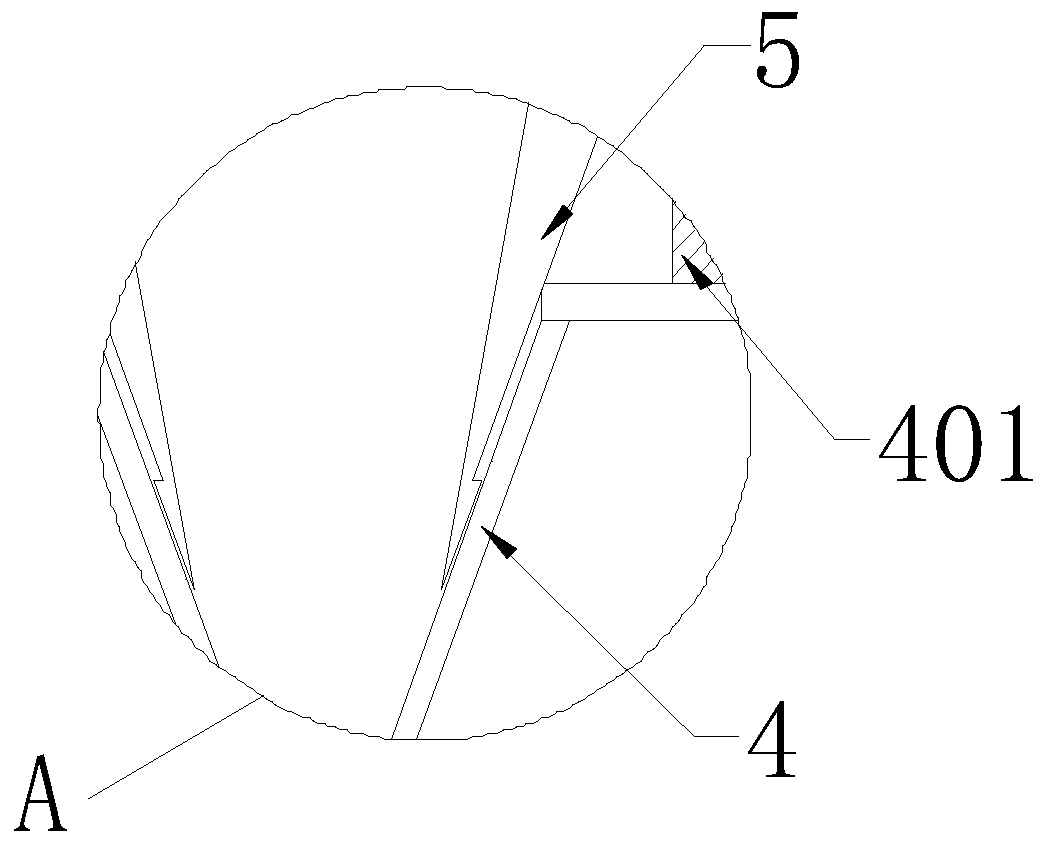

Ditching and fertilizer applying machine

InactiveCN104798519AGood throwing effectIncrease productionPlantingFertiliser distributersAgricultural engineeringSprocket

The invention provides a ditching and fertilizer applying machine. A feed port of a fertilizer discharger (4) is communicated with a discharge port of a fertilizer box (5), a fertilizer outlet (6) of the fertilizer discharger (4) is communicated with a feed port of a fertilizer delivery pipe (7), a cutter head shaft (15) of a ditching cutter head (2) is in running fit with a rack (3), two ends of the cutter head shaft extend out of left and right sides of the rack (3) and are fixedly connected with a fertilizer discharge driving chain wheel (8) and a cutter head driving chain wheel (14) respectively, a driving chain wheel (12) of a transmission case (11) is connected with the cutter head driving chain wheel (14) through a driving chain (13), the fertilizer discharge driving chain wheel (8) is connected with a fertilizer discharge chain wheel (10) on the fertilizer discharger (4) through a fertilizer discharge chain (9), a plurality of ditching cutters (1) and wall cutters (17) are evenly and circumferentially distributed on the ditching cutter head (2), and edges of the wall cutters (17) are U-shaped. The machine is simple in structure, good in soil loosening operation effect, tight in coverage after deep application of fertilizer and high in operation efficiency.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

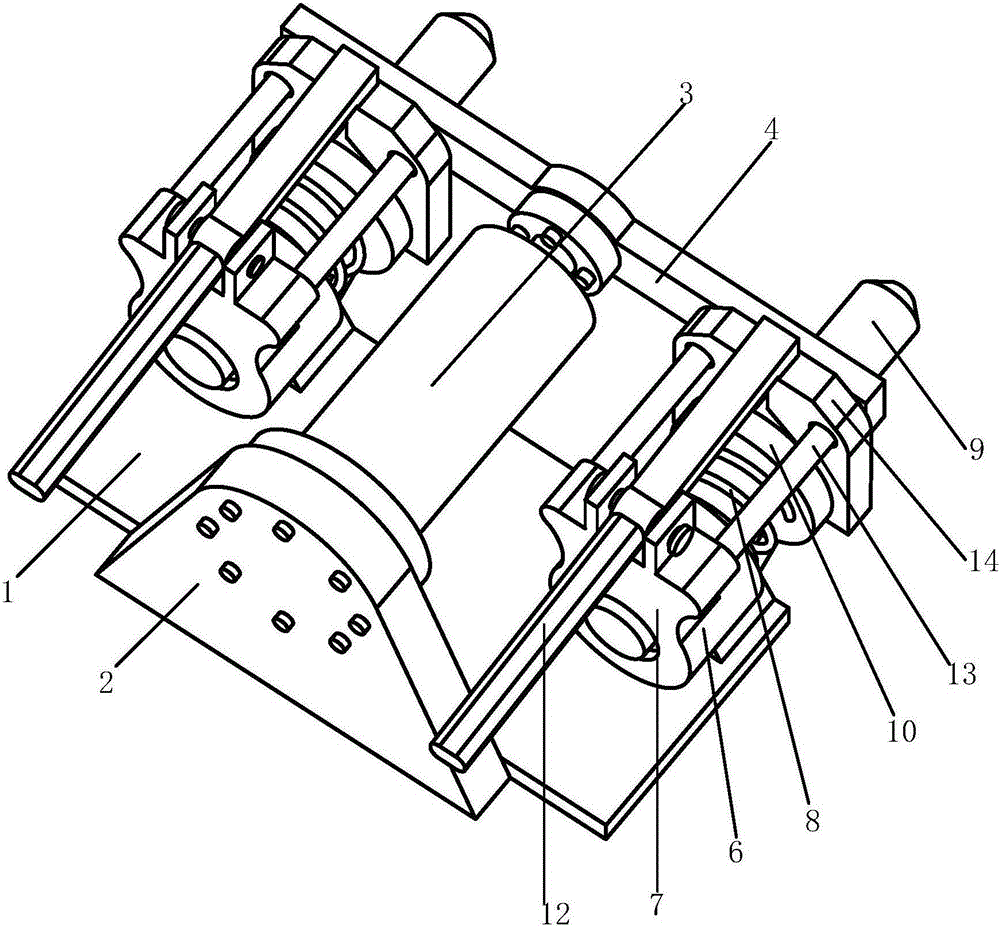

Organic fertilizer fermentation upender

InactiveCN1493551ACompact structureInnovative designBio-organic fraction processingOrganic fertiliser preparationSludgeEngineering

A fermenting-turning over machine for preparing organic fertilizer features that its lower part is an electric running mechanism with wheels, speed-adjustable motor and electric lifting unit, and its turning-over crawler belt with scraping nails on its external surface has one end connected to the axle of electric running mechanism and another end connected with said electric lifting unit. Its advantages are compact structure and high effect.

Owner:唐山市芦台农场长荣生物有机肥厂 +1

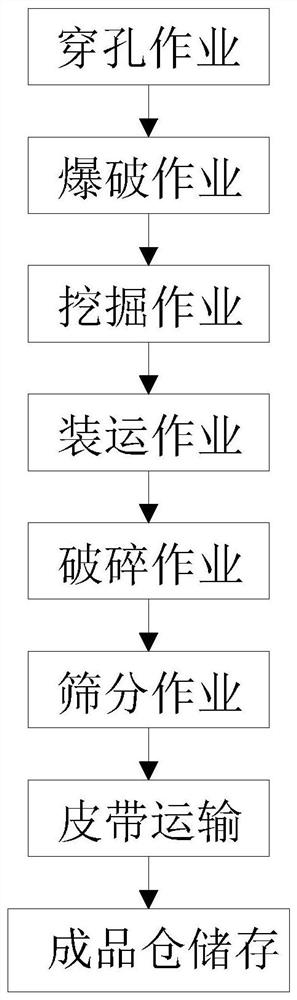

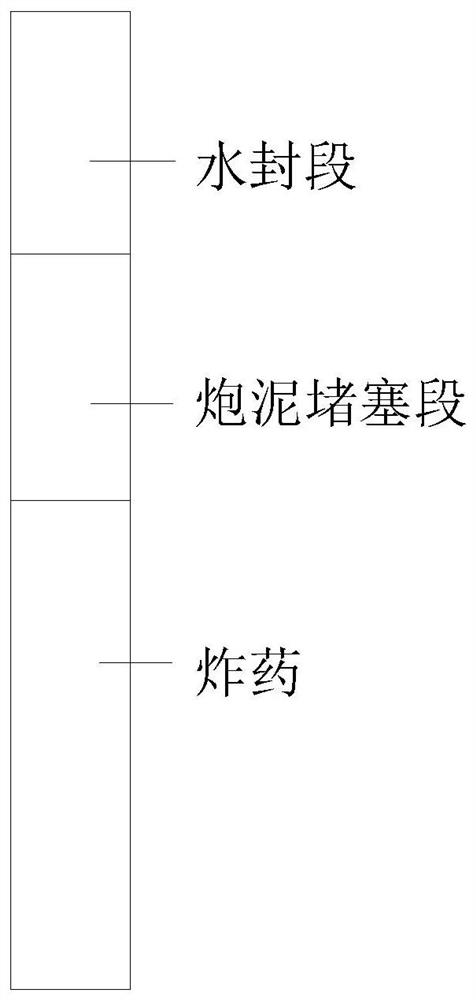

Open limestone mining method applied to environmental protection and dust fall

ActiveCN112746848AAvoid formingFast degradationUnderground miningUsing liquid separation agentDust controlRock cutting

The invention discloses an open limestone mining method applied to environmental protection and dust fall, and relates to the technical field of mining. The open limestone mining method comprises the following steps that S1, perforating operation is carried out, a wet type operation method is adopted, a high-pressure water spraying device is additionally arranged, high-pressure water is injected through the center of a drill rod during rock drilling, so that dust in a blast hole is wetted and becomes slurry, and then the slurry is blown out by high-pressure airflow blown into the center of the drill rod. According to the open limestone mining method applied to environmental protection and dust fall, a BSD foam dust suppression system is adopted, dust removal management work can be simplified, the whole dust removal system can be easily controlled by a central control room as long as water and compressed air are conveyed to all dust production points, dust removal is not needed in the dust suppression technology, secondary pollution is avoided, so that the working condition of dust removal management personnel is improved, the dust suppression system occupies a small space, the effective space in a plant can be saved, the capital construction investment is reduced, and the dust removal operation cost is greatly reduced.

Owner:邵阳市联合农林建材科技有限公司

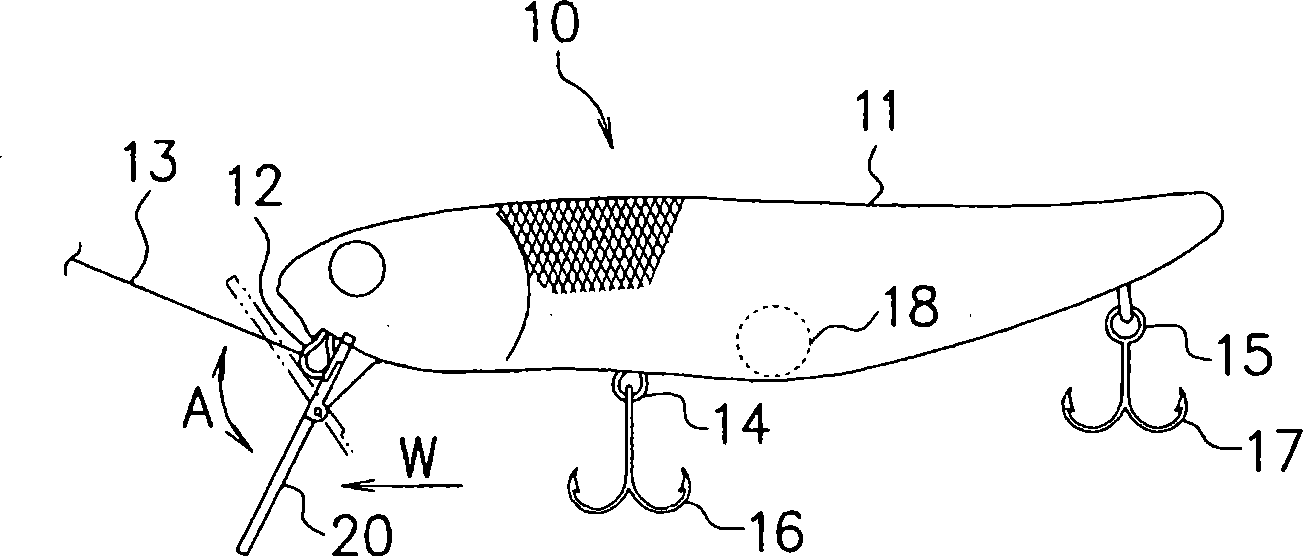

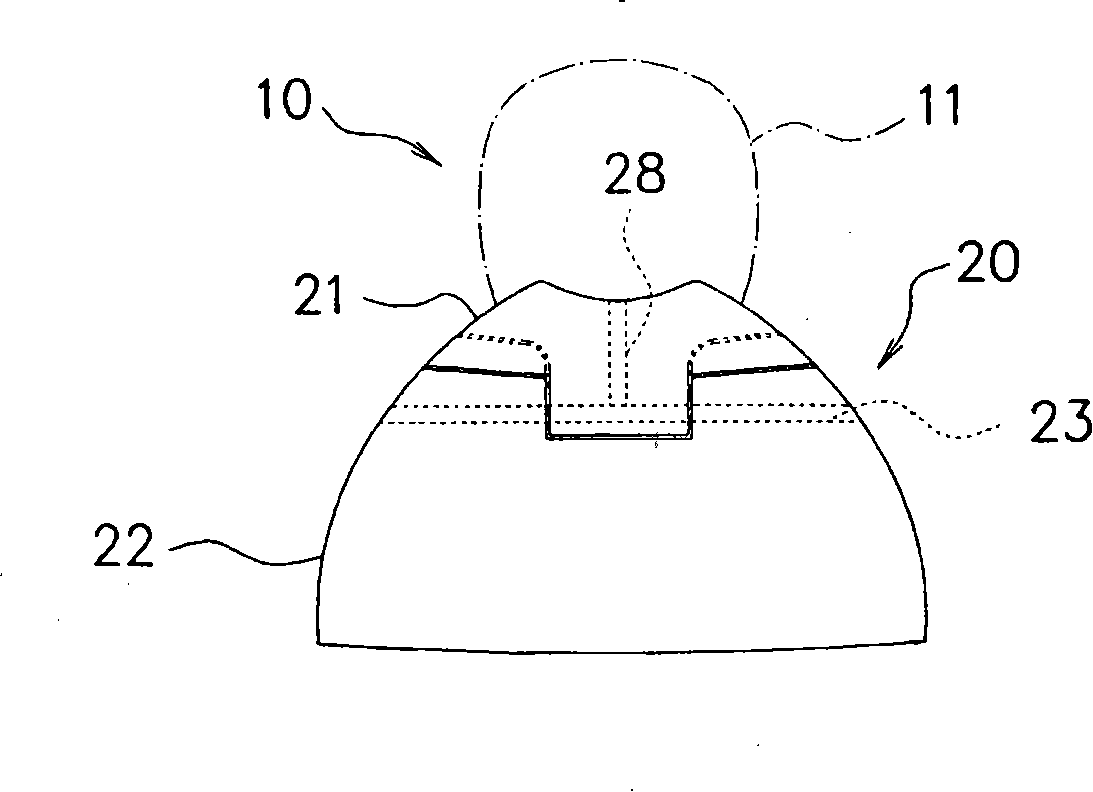

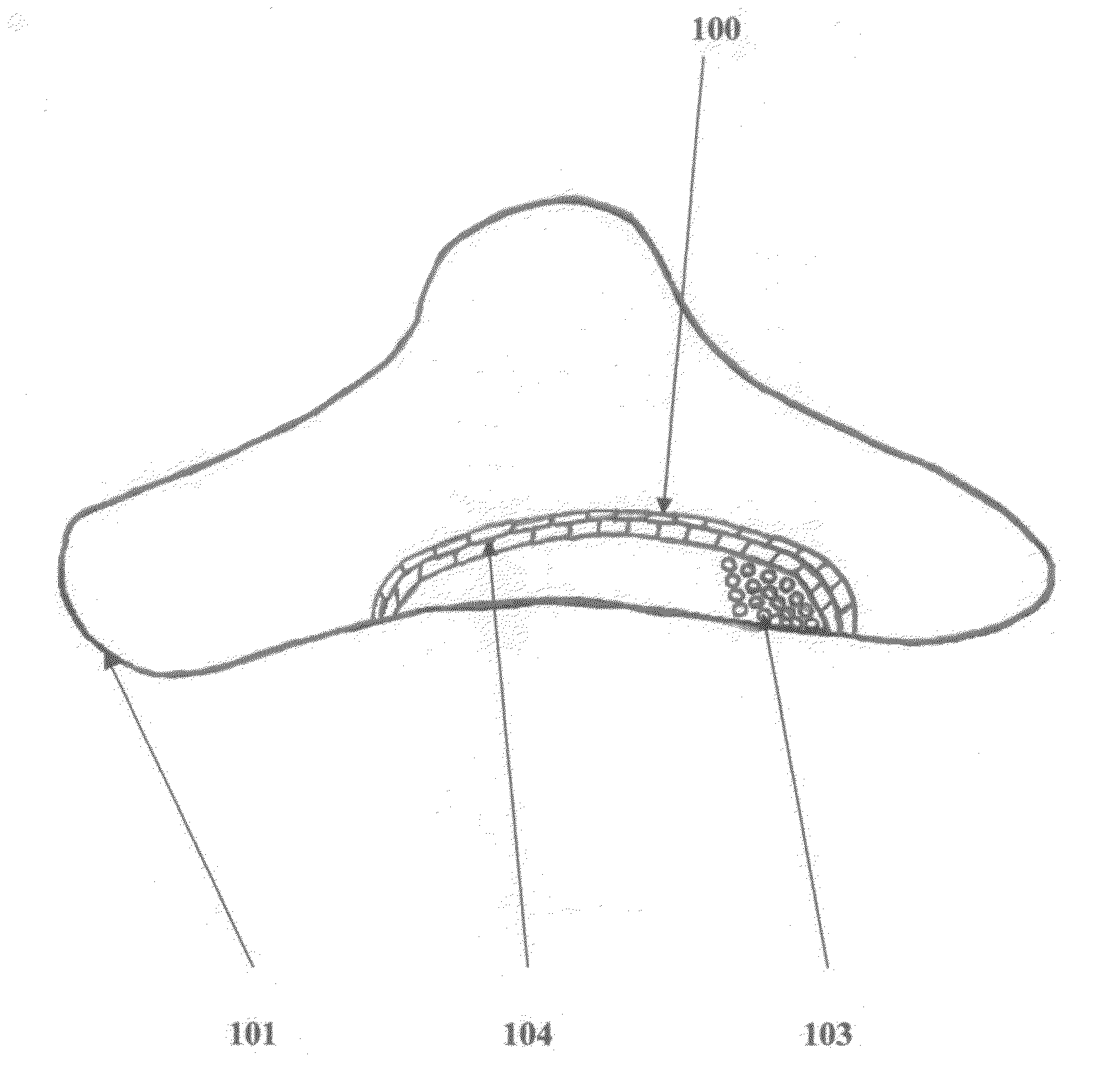

Fishing lure

The invention provides a fishing lure having excellent cast performance, and capable of realizing effective lure actions. The fishing lure includes a lure body formed to have an appearance imitating a small fish. The lure body is provided with a bendably structured diving plate in the vicinity of the tip of the lure body. The diving plate is made to be bendable by connecting the upper portion and the lower portion of the diving plate bendably in a manner that the lower portion is vertically pivotable in regard to the upper portion fixed on the lure body.

Owner:伊东浩一

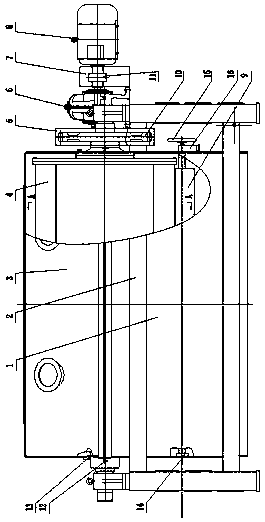

Fine grain dry separator for weakening magnetic effect loss

ActiveCN107597422ASimple structureExtended service lifeMagnetic separationMagnetic effectReduction drive

The invention discloses a fine grain dry separator for weakening magnetic effect loss and belongs to the technical field of magnetic ore separating machines. The fine grain dry separator comprises a lower box, a rack, an upper box, a permanent magnet barrel, a speed reducer, a motor, an ore discharging adjusting device, a gear, a base, an adjusting plate support and the like. The lower box is fixed to the rack through bolts. An axle bed of the permanent magnet barrel is arranged on the rack and connected to the rack through bolts. The permanent magnet barrel is arranged in the upper box and the lower box. A connecting position of the upper box and the lower box is sealed through soft rubber, and connection is achieved through bolts. The surfaces of contact between the permanent magnet barrel and the upper box and the lower box adopt sealing materials for sealing. One end of the ore discharging adjusting device is inserted into an internal seat of the lower box, and the other end of theore discharging adjusting device is arranged outside a lower box body to be connected with an adjusting handle. The permanent magnet barrel is connected with the speed reducer through the gear, and the speed reducer is connected with the motor through a coupler. The fine grain dry separator provided by the invention is simple in structure and convenient to maintain and repair, energy is saved, the service life of equipment is prolonged, and power loss caused by magnetic effect is reduced.

Owner:NORTHERN HEAVY IND GRP CO LTD

Mine protective net throwing device

Owner:安徽省无为煤矿机械制造有限公司

Fertilizer turner equipment

InactiveCN106747740ASimple methodLow costBio-organic fraction processingOrganic fertiliser apparatusComing outSlide plate

The invention provides fertilizer turner equipment, which comprises walking wheels, an engine case, an operating console, a crossbeam, a motor bench, a motor, supports, a guard board, a side stage and turner wheels. A. Channel steel is used for welding a case, the upper surface of the case is welded with a metal plate, multiple rotating shafts are mounted on the upper surface of the case, the rotating shafts and the case are in shaft connection, the rotating shafts are coated with a conveyor belt, the motor is fixedly installed at one side of the case, and the motor is in transmission connection with the belt between the rotating shafts at end portions so as to further drive the conveyor belt to move; B. a feed hopper is installed above one end of the case, a discharge pipe is fixedly installed below the feed hopper, and the discharge pipe is suspended over one end portion of the conveyor belt; and a fertilizer slide-plate is installed below the other end portion of the conveyor belt, and the fertilizer slide-plate is fixedly connected to the case; and C. multiple blower boxes are fixedly installed at one side of the upper surface of the case, a fan is arranged inside the blower box, the fan and the blower box are in shaft connection through a fan shaft, and the fan is positioned above the conveyor belt. The method is simple. The equipment is convenient to use and can rapidly cool. Fertilizer granules can be cooled and packaged in bags after coming out of a drying cylinder. Therefore, manufacturing time is saved and production efficiency is enhanced.

Owner:DANGSHAN CHUNYUAN FERTILIZER CO LTD

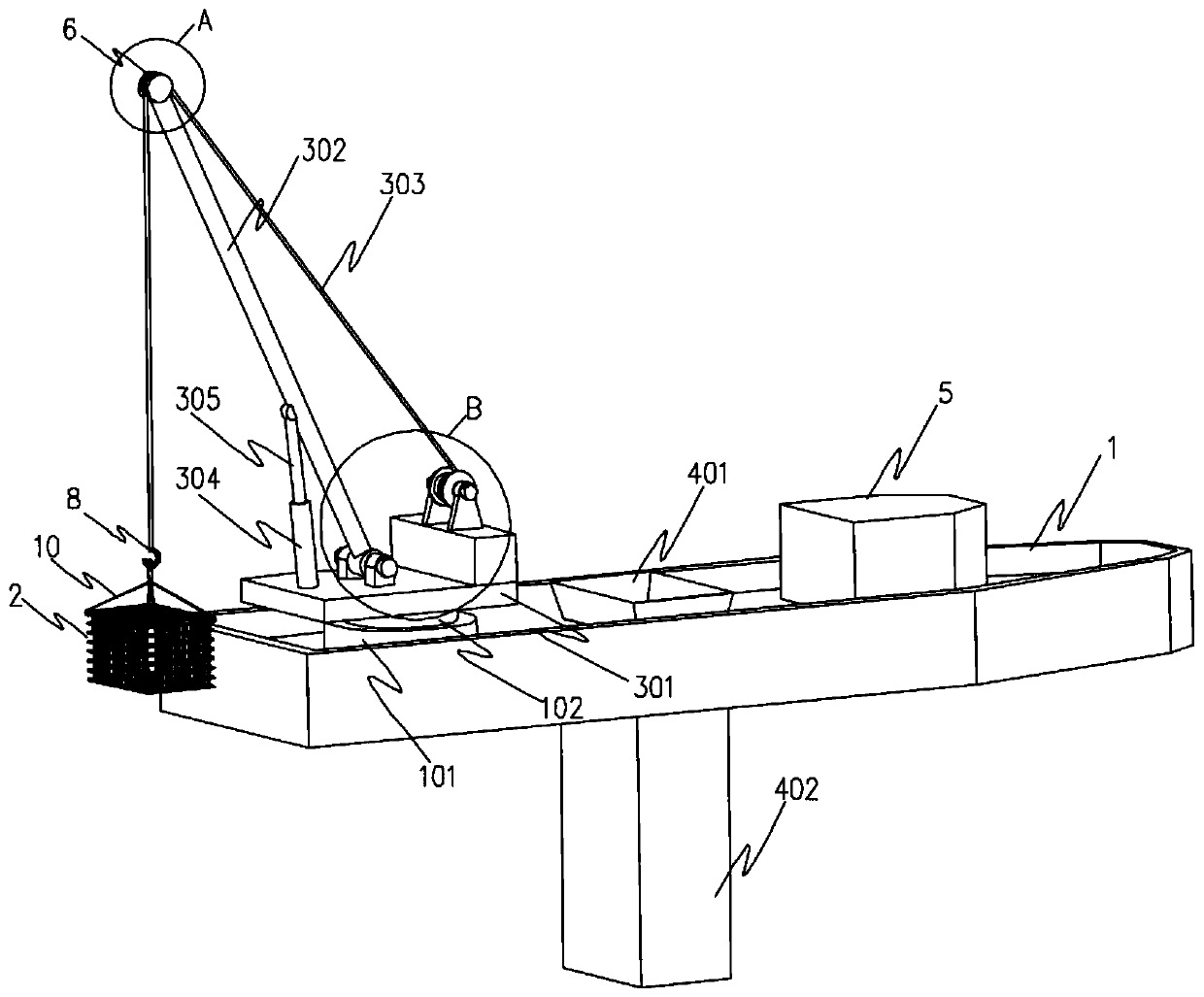

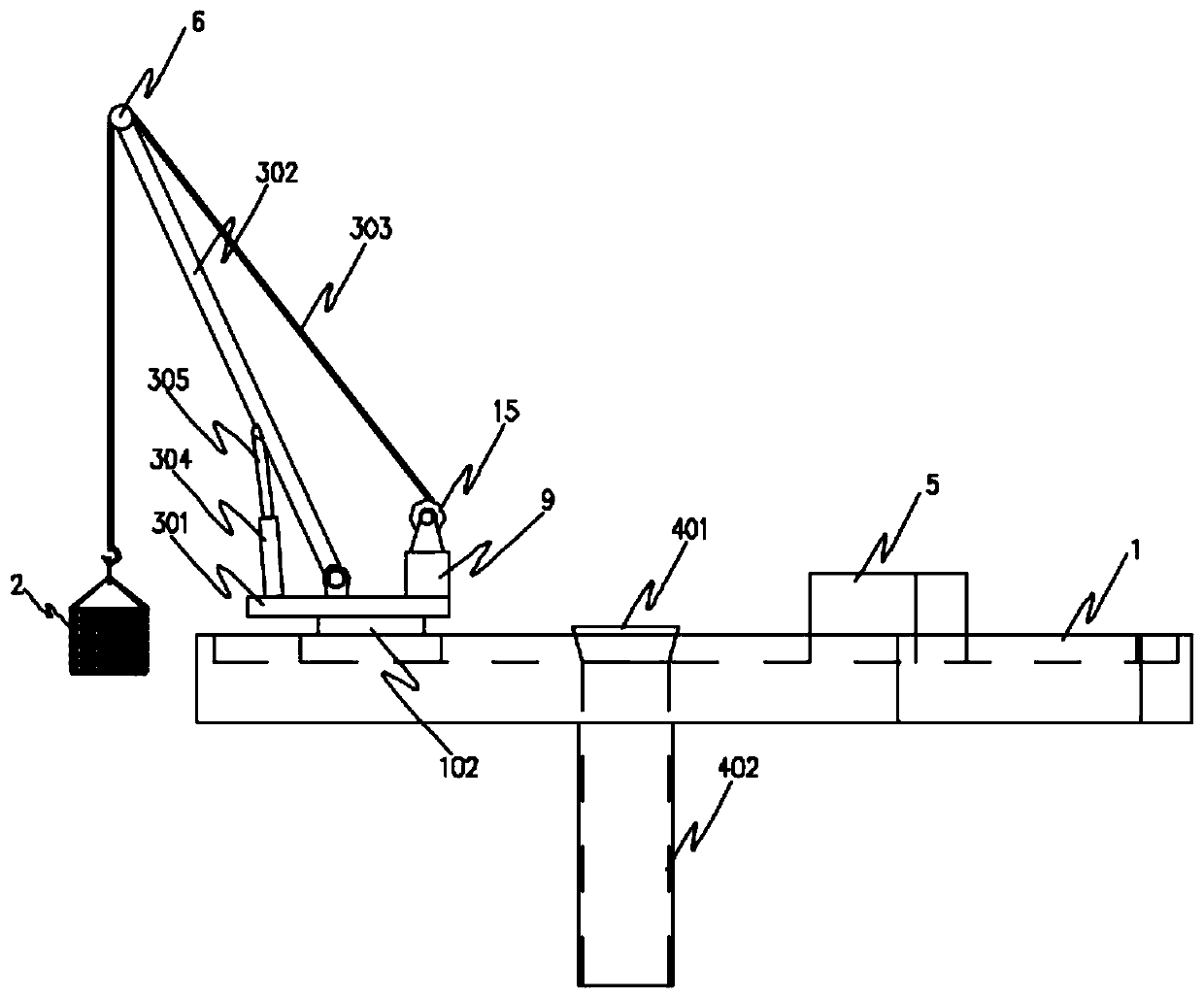

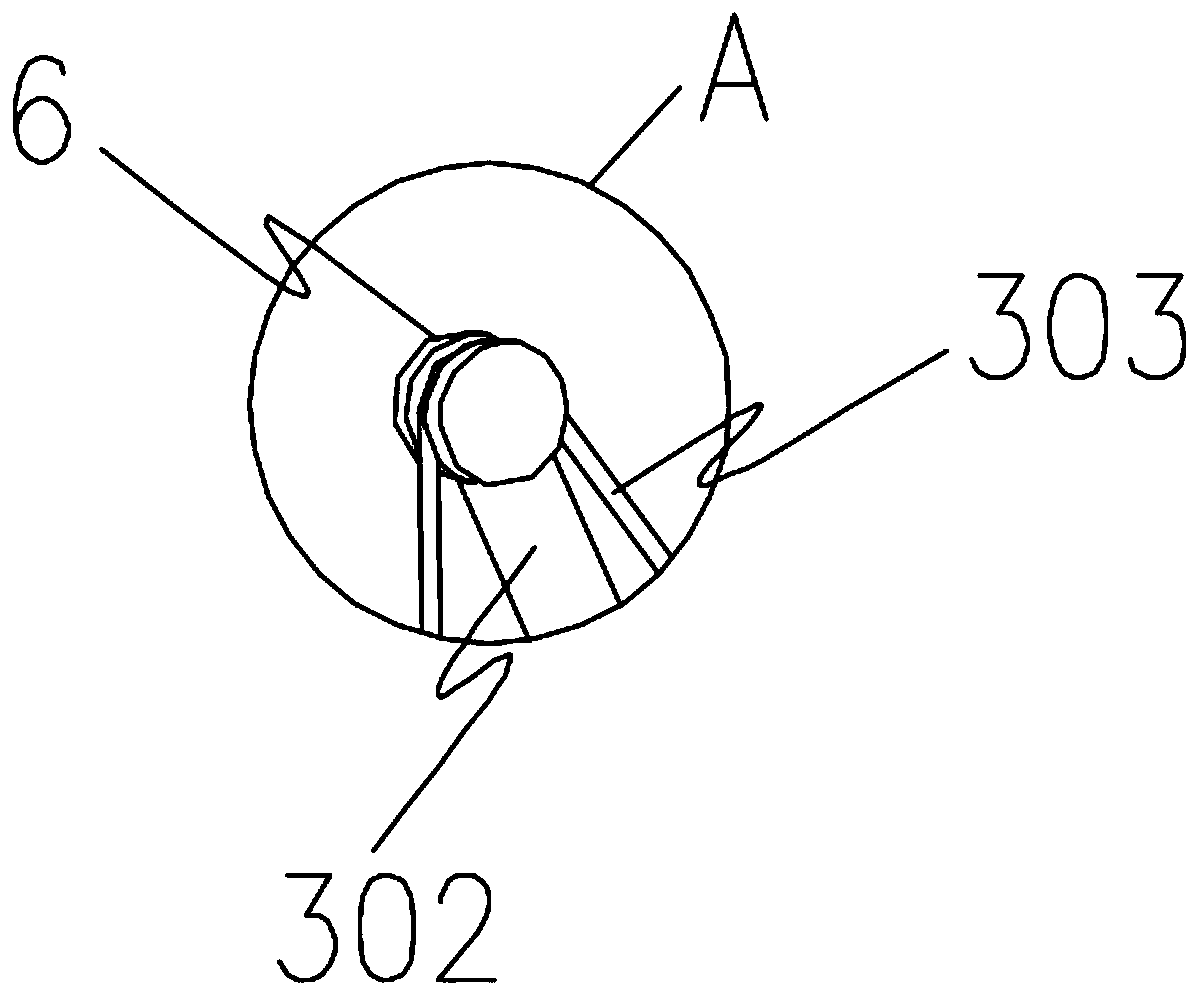

Reinforcing mesh cage stone throwing device and use method

InactiveCN111576429AImprove construction efficiencyImprove the effect of remediationWaterborne vesselsFoundation engineeringRebarMarine engineering

The invention relates to a reinforcing mesh cage stone throwing device and a use method. The reinforcing mesh cage stone throwing device comprises a stone showing ship, a mesh cage, a lifting assemblyand a throwing assembly; a flight deck is arranged on the stone throwing ship, and the flight deck is arranged is arranged at the front end of the stone throwing ship; the lifting assembly and the throwing assembly are arranged on the stone throwing ship; and the mesh cage is used for loading and transporting the thrown stones. The use method is simple to operate, easy to control and high in adaptability. The problems in the prior art that the thrown stones cannot be distributed at the bottom of a riverbed uniformly due to low stone throwing precision and non-uniform grain size of the thrownstones, even a missing throwing area occurs are solved. The stone throwing position and quantity are positioned and quantitatively controlled in the stone throwing construction process; the control precision of throwing stones underwater is improved, and the construction efficiency and the treatment effect are enhanced.

Owner:CCCC SHANGHAI DREDGING

Novel throwing machine

ActiveCN103896028AGood throwing effectSave resources and costsThrowing machinesEngineeringConveyor belt

The invention relates to a novel throwing machine. The novel throwing machine comprises a machine frame board and a throwing bin which is fixed on the machine frame board, the top of the throwing bin is provided with a feeding port, the side face of the throwing bin is provided with a discharging port, a conveying belt is arranged on the upper portion in an inner cavity of the throwing bin, and two sides of the conveying belt are arranged at the feeding port end and the discharging port end of the throwing bin. The novel throwing machine further comprises a high-speed conveyor belt, a motor and a rotating roller, the high-speed conveyor belt is arranged on the lower portion in the inner cavity of the throwing bin, one side of the high-speed conveyor belt is arranged at the discharging port end, the other side of the high-speed conveyor belt is arranged on one side, away from the discharging port, of the bottom of the throwing bin, the motor is arranged on the part, outside the throwing bin, of the machine frame board, the rotating roller is arranged in the throwing bin and pressed on the inner surface of the high-speed conveyor belt, and the rotating roller is connected with the motor through a belt. By means of the novel throwing machine, scattered materials do not need to be cleared away manually, the throwing effect is good, resources and cost are saved, and manpower is saved.

Owner:铜陵有色兴铜机电制造有限公司

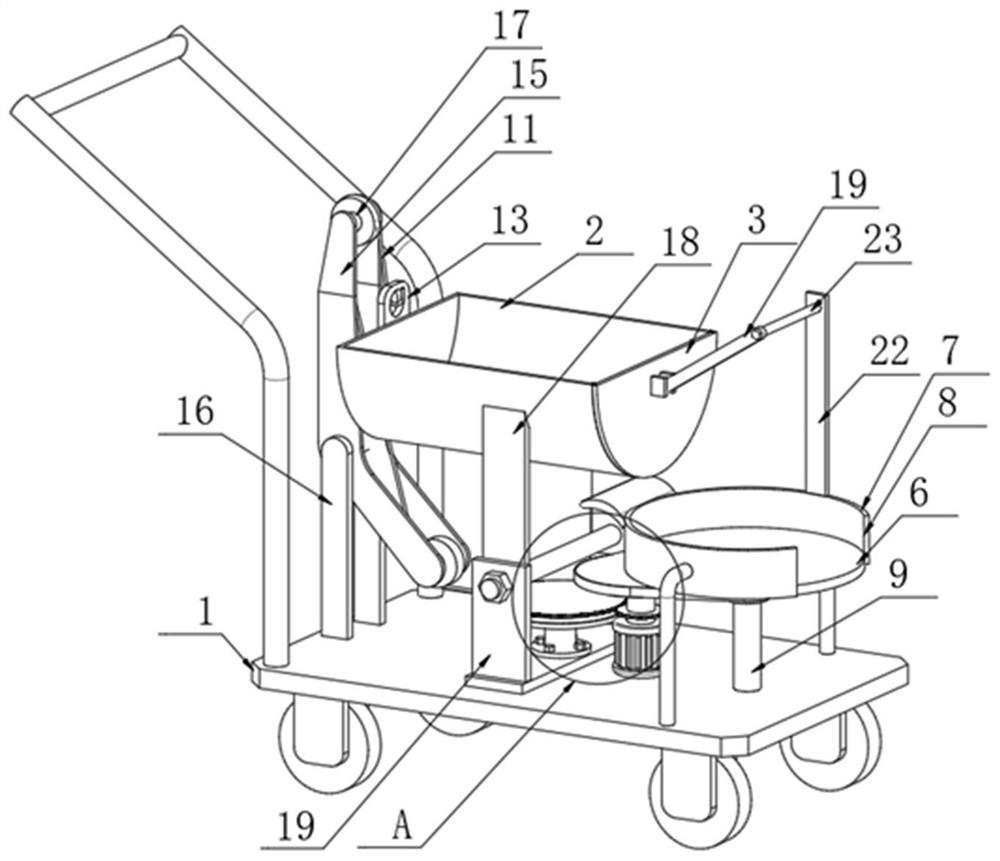

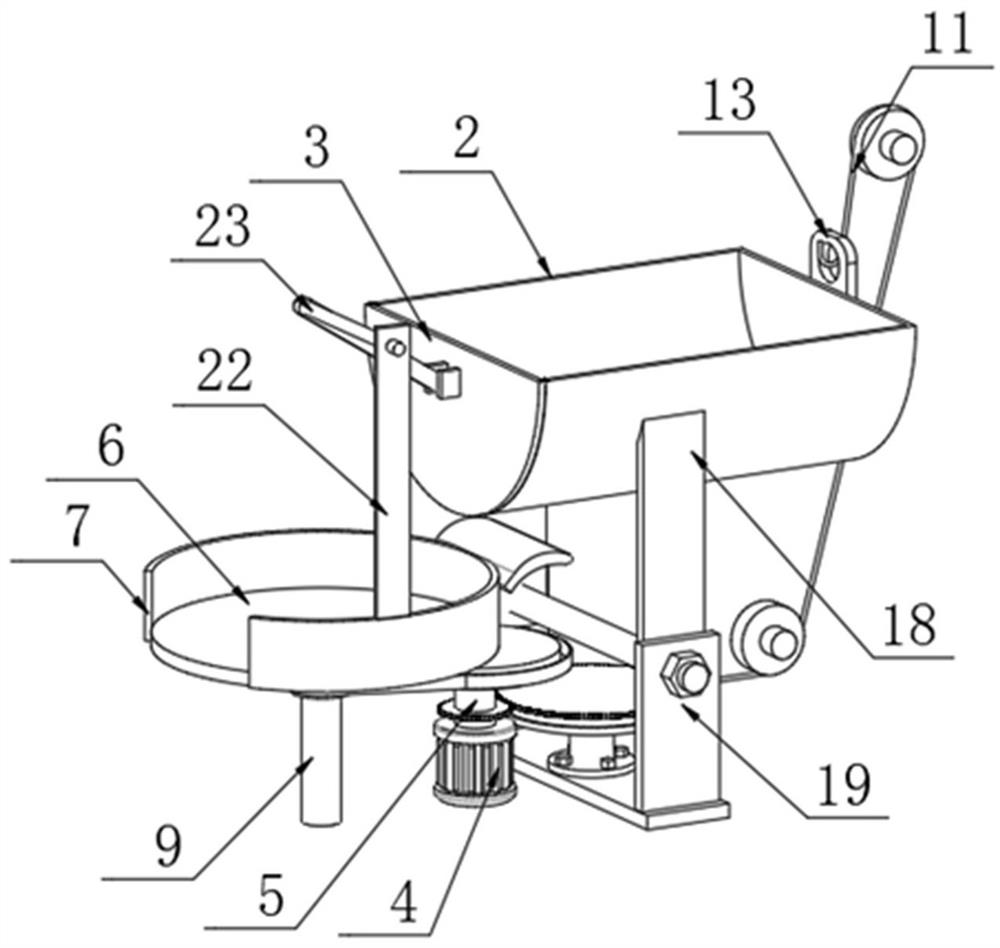

Feeding feed throwing equipment for livestock and poultry breeding and using method thereof

InactiveCN112205309AEasy and fast tossReduce labor intensityAnimal feeding devicesAvicultureAnimal scienceAgricultural science

The invention provides feeding feed throwing equipment for livestock and poultry breeding and a using method thereof, and relates to the technical field of livestock and poultry feeding. The feeding feed throwing equipment for livestock and poultry breeding comprises a bottom plate, wherein the top end of the bottom plate is rotationally connected with a material groove, a lifting assembly is arranged at one end of the top of the material groove, a throwing assembly is arranged at the other end of the bottom of the material groove, a door plate is arranged at the other end of the material groove, the door plate is hinged to the material groove through a hinge, the throwing assembly comprises a motor, and the output end of the motor is fixedly connected with a transmission shaft. Accordingto the feeding feed throwing equipment for livestock and poultry breeding, feed can be thrown out through a notch in the outer side of an annular baffle under the action of centrifugal force, so thatthrowing of the feed is achieved, the feed can be thrown conveniently and rapidly through cooperation of the rotating material groove and a rotating plate, the labor intensity of workers can be greatly relieved, and the feeding feed throwing equipment is compact in structure, good in throwing effect and convenient to popularize.

Owner:萧县年年养鱼农民专业合作社

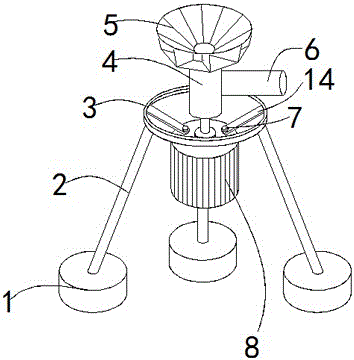

Material throwing device for pond culture

InactiveCN106135104AFully automatedRealize intelligencePisciculture and aquariaWater qualityElectric machinery

The invention discloses a material throwing device for pond culture. The material throwing device comprises floating balls, a bracket, a fixed plate, a tube, a material throwing tray, a guide housing, bolts, a high-speed motor, a temperature sensor, a camera, a water quality detector, a rotating shaft, a blade, fixing rods, processors and controllers, wherein the bracket is arranged at the upper parts of the floating balls, and the other end of the bracket is connected with the fixed plate; the fixed plate is provided with the fixing rods, the fixing rods are connected with the high-speed motor by the bolts, and an output shaft of the high-speed motor is connected with the rotating shaft; the tube sleeves the outer side of the rotating shaft; the guide housing is arranged at one side of the tube; the blade is arranged at a connecting part of the guide housing and the tube; a circular hole through which the rotating shaft can pass is formed in the middle of the blade; the material throwing tray is arranged at the upper part of the tube. The material throwing device enables throwing to be uniform by mechanical material throwing, thus saving manpower; furthermore, the material throwing device has functions of water quality monitoring and the like, thus realizing the automation and intellectualization of the pond culture, and meeting the demands of the pond culture.

Owner:ZHUHAI QIANGJING AGRI CO LTD

Fishpond aeration feeding device

ActiveCN109937941APrevent leakageIncrease contact areaClimate change adaptationPisciculture and aquariaWater flowElectric machinery

The invention provides a fishpond aeration feeding device. The fishpond aeration feeding device comprises a fixed box, a fixing support, a water outlet pipe, an inclined bucket, a fixing shaft, a balance rod, a balance weight rod, a blocking rod, a conveying pipe, an spring column, a cutting mesh, a storage bucket, an extending motor, an extending column and a pressing; the circumference of the fixed tank is fixedly provided with the fixing support, and the top surface of the fixing tank is fixedly provided with the water outlet pipe; one end of the fixing support, which is away from the fixedtank, is provided with the fixing shaft; the circumference of the fixing shaft is wrapped by the inclined bucket; the circumference of the inclined bucket is provided with the balance rod; one side of the balance rod is provided with the balance weight rod; one side of the balance rod, which is away from the balance weight rod, is provided with the blocking rod; one side of the blocking rod, which is away from the inclined bucket, is provided by adhesion with the conveying pipe. With different weight, the balance rod, the balance weight rod and the blocking rod can rotate at different speedsunder water impact to increase the feed spreading range and further improve the scattering effects.

Owner:聊城市苍禾农业科技有限公司

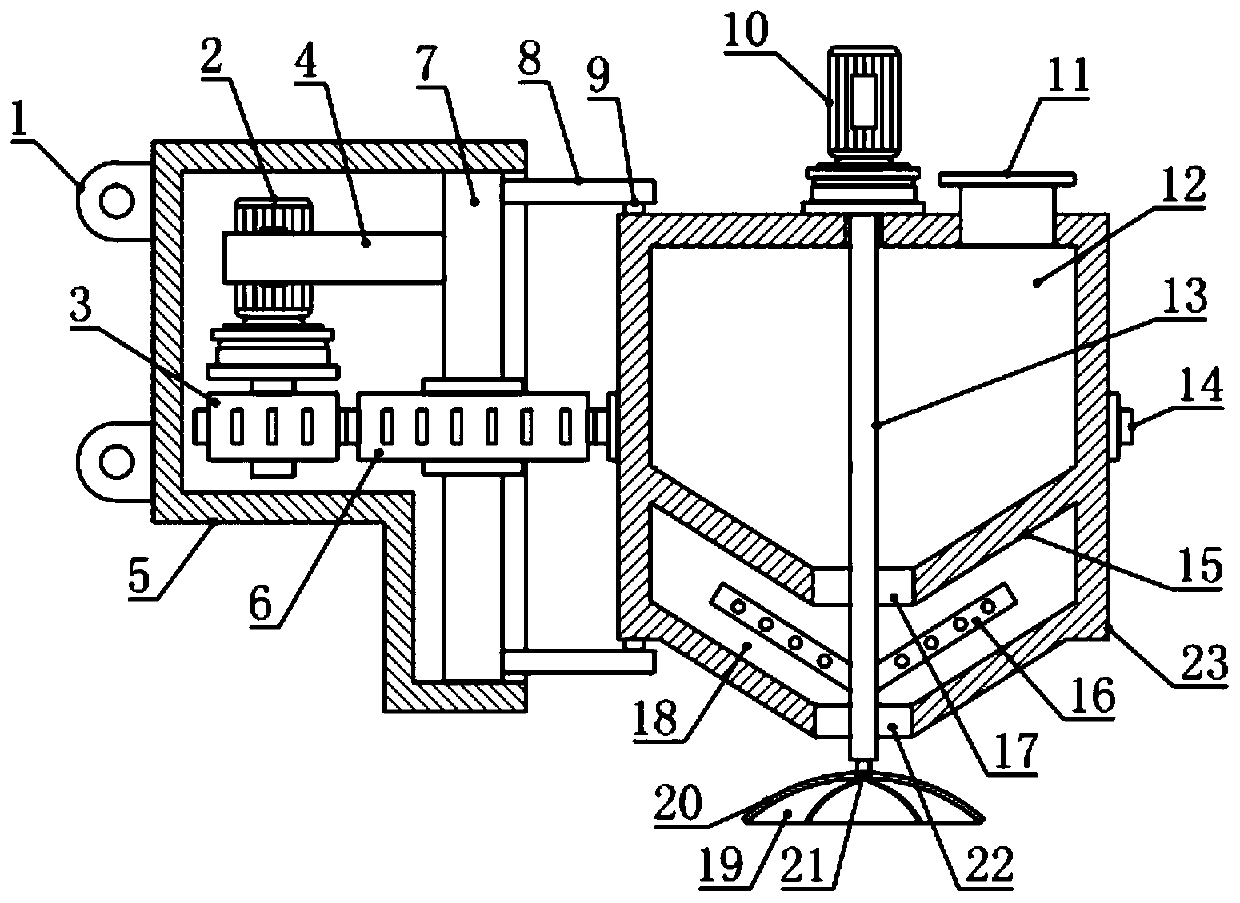

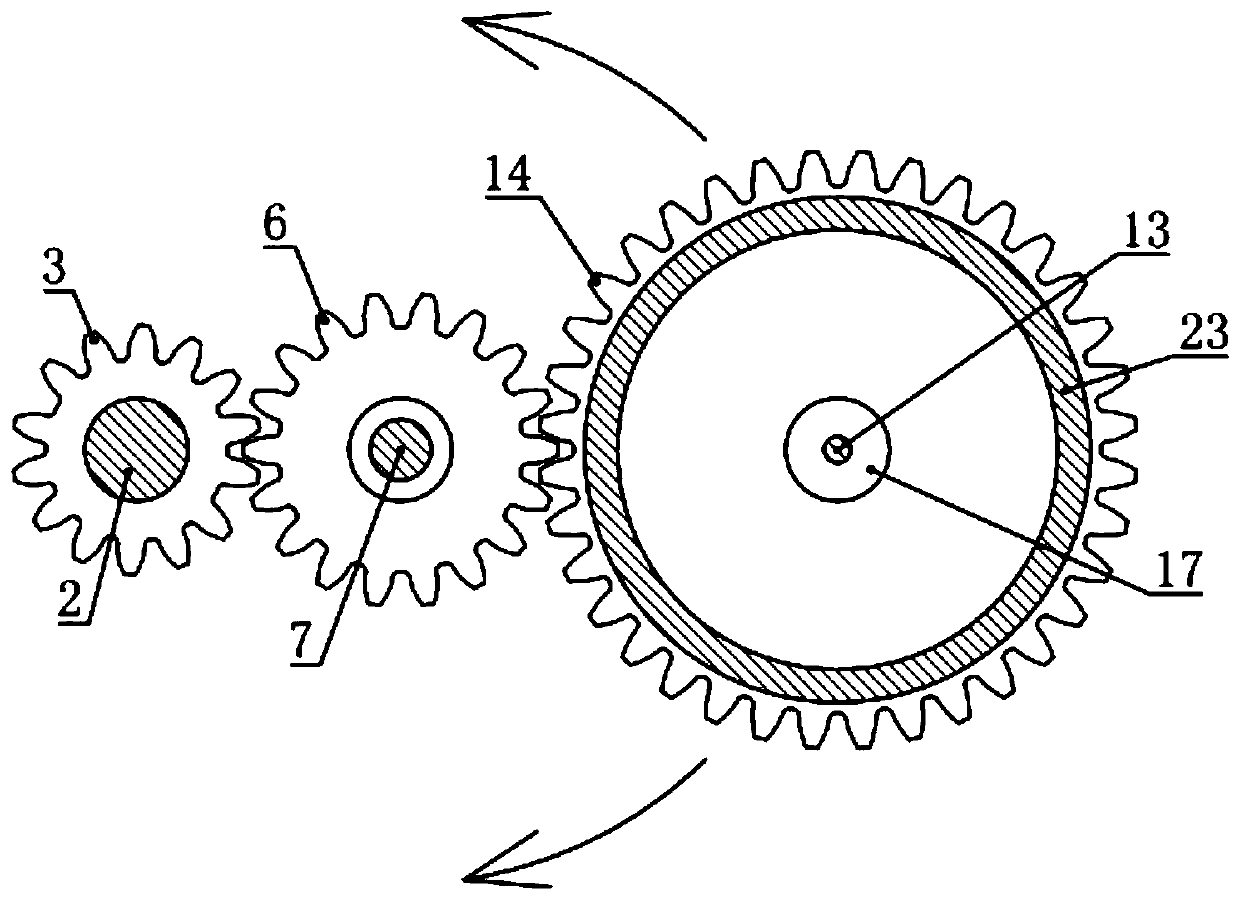

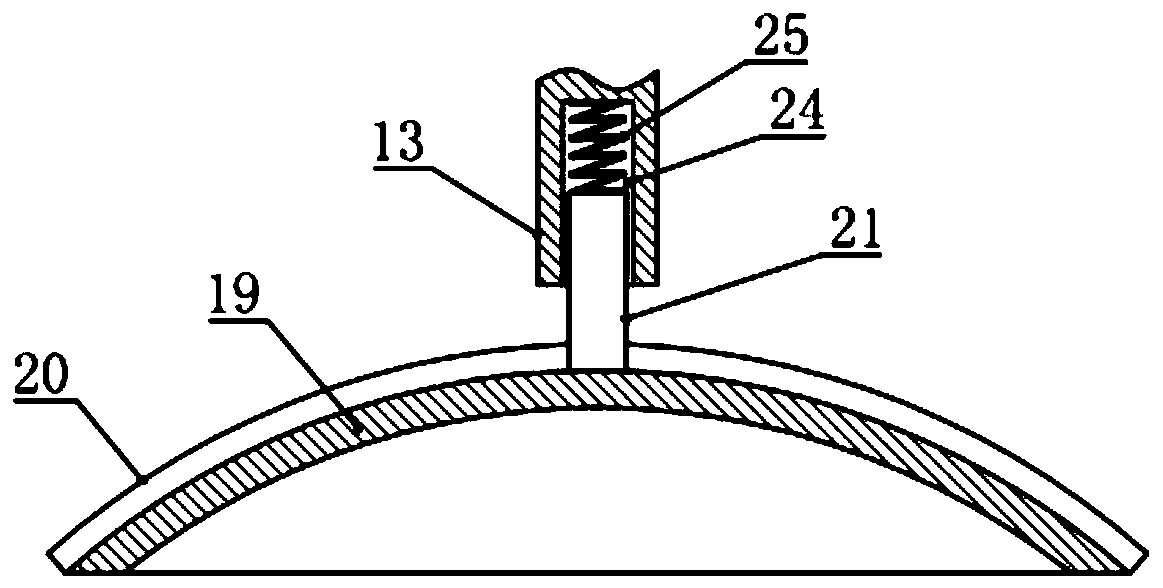

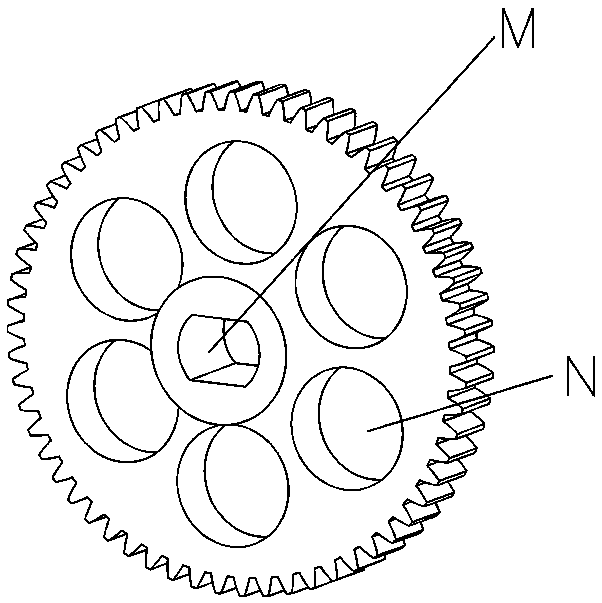

Throwing type fertilizer applying device for agricultural planting

ActiveCN111296023AWell mixedReduce work intensityTransportation and packagingRotary stirring mixersGear driveGear wheel

The invention relates to the field of agricultural planting, and particularly relates to a throwing type fertilizer applying device for agricultural planting. The throwing type fertilizer applying device comprises a mounting box and a machine body, wherein a fixed support assembly is arranged in the mounting box; a first motor is fixedly arranged at one side of the fixed support assembly, and themachine body is rotationally arranged at the other side of the fixed support assembly; the first motor is connected with the machine body through a gear transmission assembly; a separating plate is arranged in the machine body; a material storage cavity and a uniform mixing cavity are respectively arranged at the upper side and lower side of the separating plate; a stirring shaft is arranged in the middle part of the machine body; a second motor is arranged at the top part of the machine body and is used for driving the stirring shaft to rotate; a uniform mixing plate is arranged on the stirring shaft in the uniform mixing cavity; and a throwing disc is arranged at the lower end of the stirring shaft through an elastic telescopic assembly. The throwing type fertilizer applying device has the advantages that the fertilizer applying range is large, the uniform mixing effect of the fertilizer is good, and the fertilizer applying effect and efficiency are improved.

Owner:李琴

Bio-organic fertilizer turning and throwing equipment

InactiveCN113880623AGuaranteed oxygen contentIncrease contact timeBio-organic fraction processingOrganic fertiliser preparationSuspended particlesDrive wheel

The invention belongs to the technical field of organic fertilizer production equipment, and discloses bio-organic fertilizer turning and throwing equipment. The equipment comprises a self-propelled turning and throwing machine body, wherein the turning and throwing machine body is connected with a driving motor, the driving motor is connected with a rotating belt body, the feeding end of the rotating belt body is lower than the discharging end of the rotating belt body, a rotating belt of the rotating belt body is connected with a plurality of turning and throwing bodies, the turning and throwing machine body is rotationally connected with a crushing bottom plate, a supporting rod, a spraying pipe and a crushing cutter, the crushing bottom plate is arranged on the lower side of the discharging end of the rotating belt body and connected with crushing teeth, a supporting sliding groove is formed in the lower side of the crushing bottom plate and slidably connected with a supporting sliding block, a supporting rod is connected with a supporting arm, a connecting shaft of the crushing cutter is connected with a driven wheel, a driving shaft of the rotating belt body is connected with a driving wheel, and a transmission belt is arranged between and connected with the driving wheel and the driven wheel. The bio-organic fertilizer turning and throwing equipment solves the problems that in the turning and throwing process of bio-organic fertilizer in the prior art, the content of suspended particles in air is high, and the fertilizer is caked after turning; and the bio-organic fertilizer turning and throwing equipment is suitable for turning of the bio-organic fertilizer.

Owner:重庆福纳斯生物技术有限公司

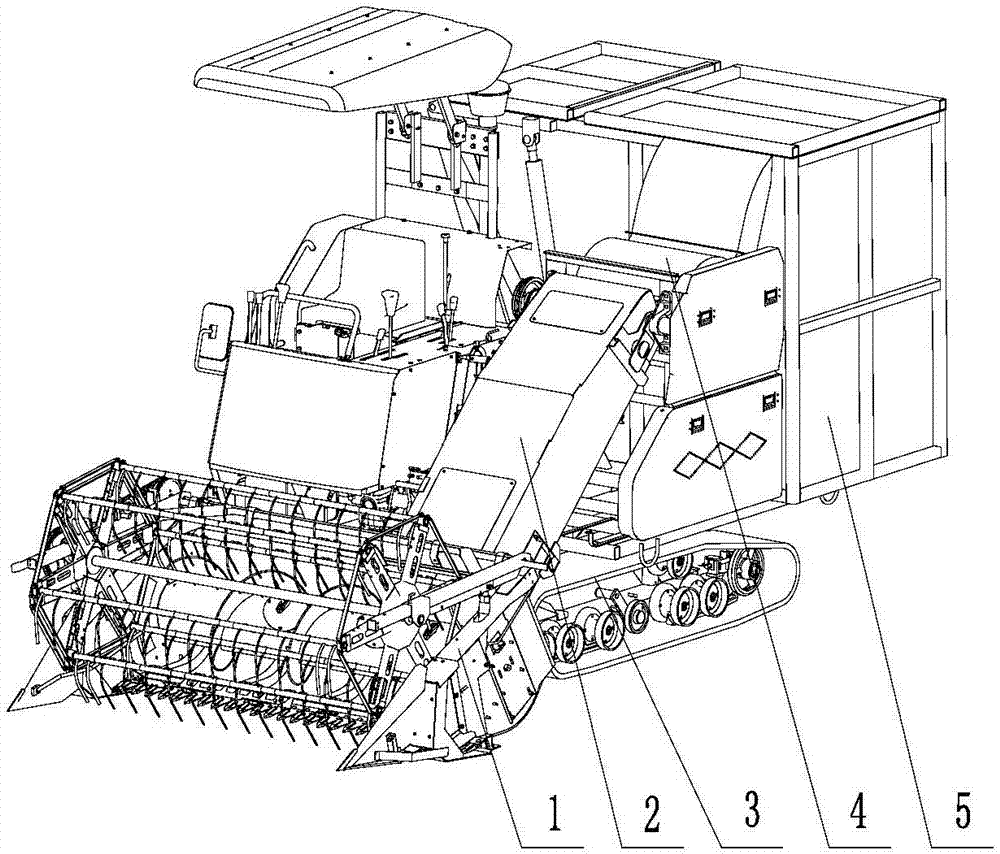

Chopping device for combined harvester of forage rape

ActiveCN107493812AChopped StableSimple structural design and manufactureMowersPillow block bearingCombine harvester

The invention discloses a chopping device for a combined harvester of forage rape. The chopping device comprises a supporting frame, a lower housing, an upper housing, a stationary knife combination and plate rolling chopper; the plate rolling chopper comprises a plate rolling chopper base in a hollow cylinder shape, chopper rib plates and a chopper main shaft penetrating the plate rolling chopper base in the axial direction with the two ends extending out of the chopper rib plate respectively and two moving knife supporting plate sets welded to the plate rolling chopper base, and the two ends of the chopper main shaft are fixed to side beams on the two sides of the supporting frame through pillow block bearings respectively. Blades of the chopper are distributed in a bilateral staggered mode, the distribution gaps meet a condition that when a previous moving knife edge leaves a stalk layer, a subsequent moving knife edge just enters the stalk layer, so that even load and small fluctuation of a roller spindle during working of the chopper are achieved; by means of distribution in a bilateral staggered mode, materials can be gathered to the middle for conveying, so that it is avoided that the materials are tossed and pile up on the wall surfaces of the two sides of each housing, and throwing of the materials to a material collecting box is promoted.

Owner:HUAZHONG AGRI UNIV

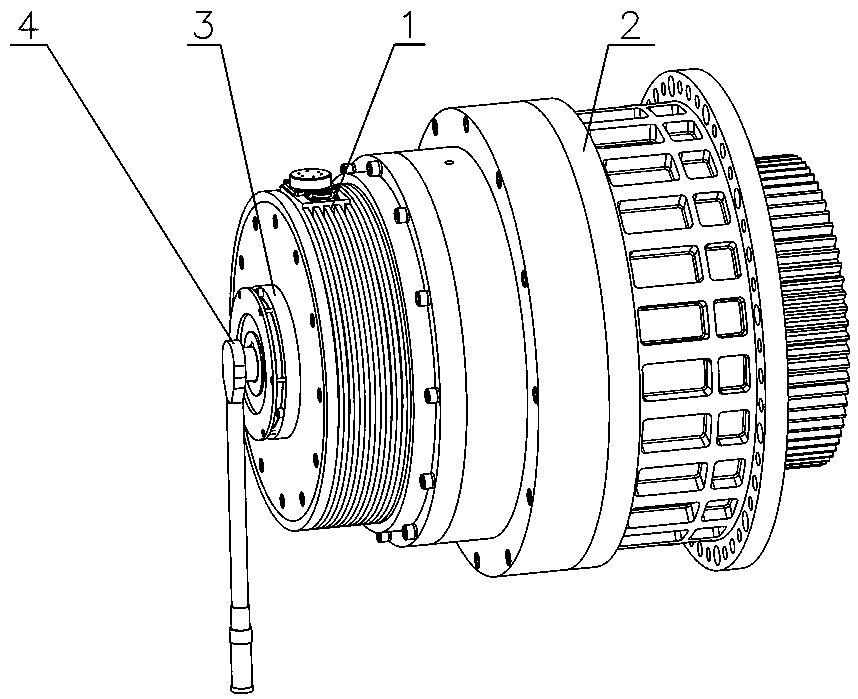

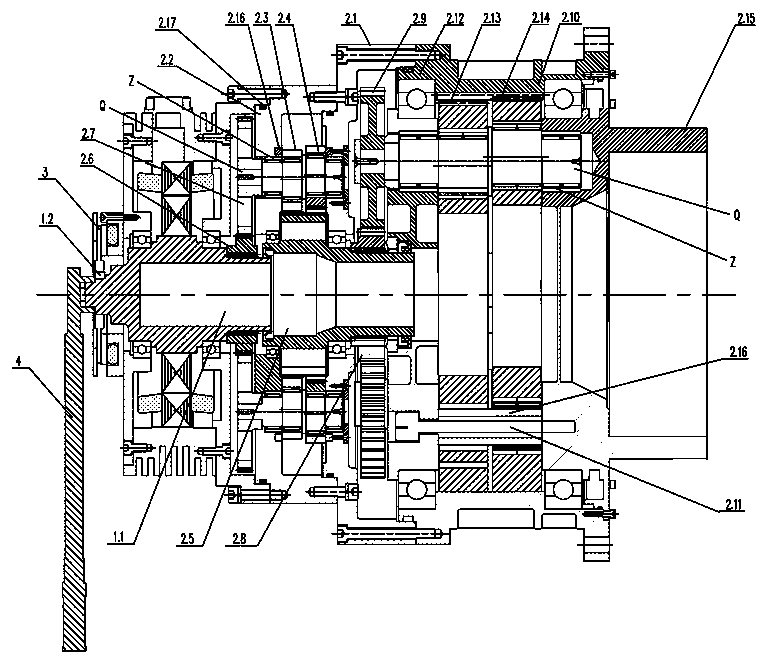

Electric driving device for rotating launching support

InactiveCN108775381AGood throwing effectIncrease flexibilityToothed gearingsBrake actuating mechanismsMicrocomputerMicrocontroller

The invention discloses an electric driving device for a rotating launching support. The electric driving device for the rotating launching support comprises an electric motor. An output shaft of theelectric motor is connected with a spline sleeve of a brake through a flat key, and the brake is arranged on the front side of the electric motor. The other end of the output shaft is connected with acenter input gear of an RV reducer in a sleeing mode, and the RV reducer is arranged on the rear side of the electric motor. A torque rotating speed sensor is arranged on the electric motor, the signal output end of the torque rotating speed sensor is connected with the signal input end of a single-chip microcomputer, and the control output end of the single-chip microcomputer is connected with the control input end of the brake. According to the electric driving device for the rotating launching support, high-speed and low-torque rotational movement of the electric motor is converted by theRV reducer into low-speed and high-torque 360-degree positive and negative rotational movement of an output part, the output shaft of the electric motor can be subjected to reliable self-locking operation through the brake after arriving at the target position and stopping, therefore the electric driving device for the rotating launching support is stable in transmission and high in locating accuracy, and is quite suitable for the situations that the throwing load is high, and the required output torque is high, and the ammunition throwing capacity and the flexibility are greatly improved.

Owner:ZHENGZHOU AIRCRAFT EQUIP +1

Frisbee throwing device based on electromagnetic effect and frisbee thereof

ActiveCN111841041AEasy to control the initial speedAccurate initial speedIndoor gamesAmusementsEngineeringStructural engineering

The invention discloses a frisbee throwing device based on an electromagnetic effect and a frisbee thereof. The device includes a slideway, a sliding hole is formed in the bottom of the slideway; slides are formed in the two sides of the inner wall of the sliding hole; the inner walls of the slides are slidably connected with limiting blocks; the sliding blocks are fixedly connected to the ends, away from the slides, of the limiting blocks; placing grooves are formed in the tops of the sliding blocks; through holes are formed in the bottoms of the placing groove; and fixing blocks are fixedlyconnected to the two sides of one end of each sliding block. Supporting shafts are fixedly connected to sides of the fixing blocks, baffles are rotatably connected to the exteriors of the supporting shafts in a penetrating mode, rotating grooves matched with the baffles are formed in the position, located below the supporting shafts, of sides of the sliding blocks, and buckle devices are arrangedat ends of the baffles. The invention relates to the field of frisbee throwing. According to the frisbee throwing device based on the electromagnetic effect and the frisbee thereof, the initial rotating speed of a frisbee can be accurately controlled, the frisbee can be prevented from being abraded, the adjustability is good, and the energy utilization rate is high.

Owner:淮北冬傲信息技术有限公司

Rice straw shattering and returning machine

InactiveCN106105573AMeet job requirementsGood throwing effectCrop conditionersMowersPulp and paper industryKnife blades

The invention relates to a returning machine, in particular to a rice straw shattering and returning machine. A suspension frame is installed in the center of the front end of a machine frame. A gearbox is installed at the front end of the upper surface of the machine frame. An output shaft is arranged at the left end of the gearbox. The output shaft is in transmission connection with one end of a flail knife roller through a first side transmission mechanism, the two ends of the flail knife roller are rotationally connected with the machine frame, the other end of the flail knife roller is in transmission connection with one end of a fixed knife roller through a second side transmission mechanism, the two ends of the fixed knife roller are rotationally connected with the machine frame, the outer circumferential face of the flail knife roller is provided with a plurality of flail knife blade sets, the outer circumferential face of the fixed knife roller is provided with a plurality of fixed knife blade sets, the rear ends of the left and right sides of the machine frame are each detachably and fixedly connected with a land wheel assembly with the adjustable land wheel height, an upper cover plate is detachably fixed to the front portion of the upper end of the machine frame, and a dispersion plate is detachably fixed to the rear portion of the upper end of the machine frame. By means of two-shaft transmission, the rotating speed can be increased, straw can be shattered to be in the shape of filaments or cotton, the shattered straw is sunk in soil, the dispersion effect is good, the dispersion range is wide, and dispersion is uniform.

Owner:韩宏宇

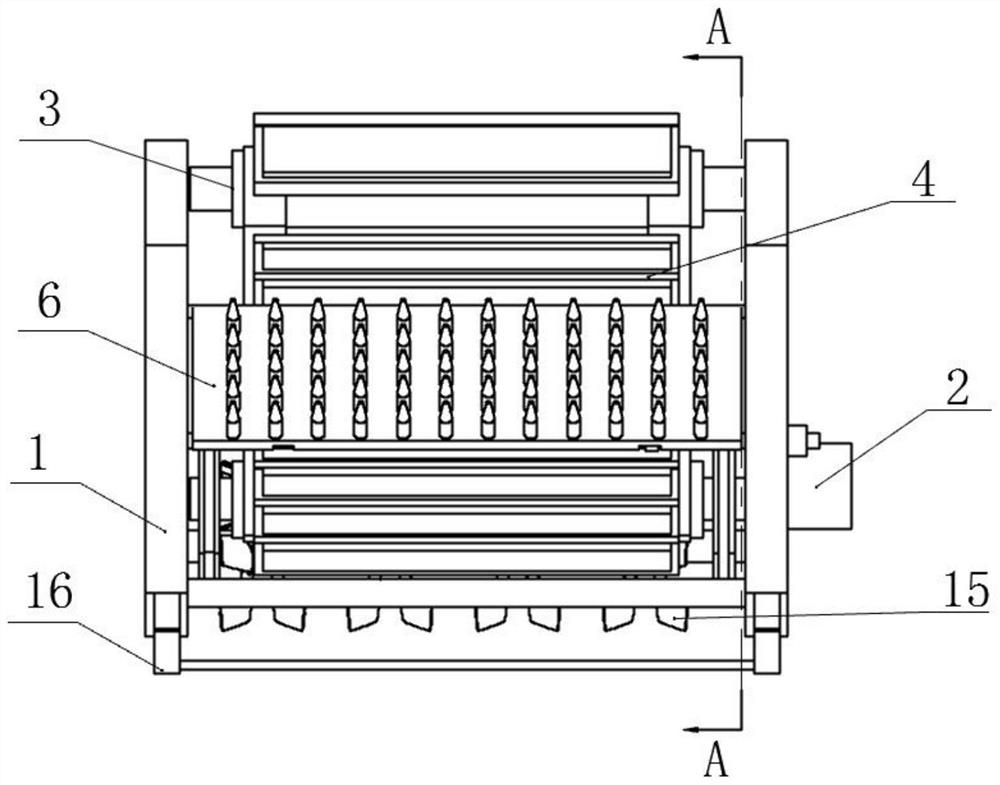

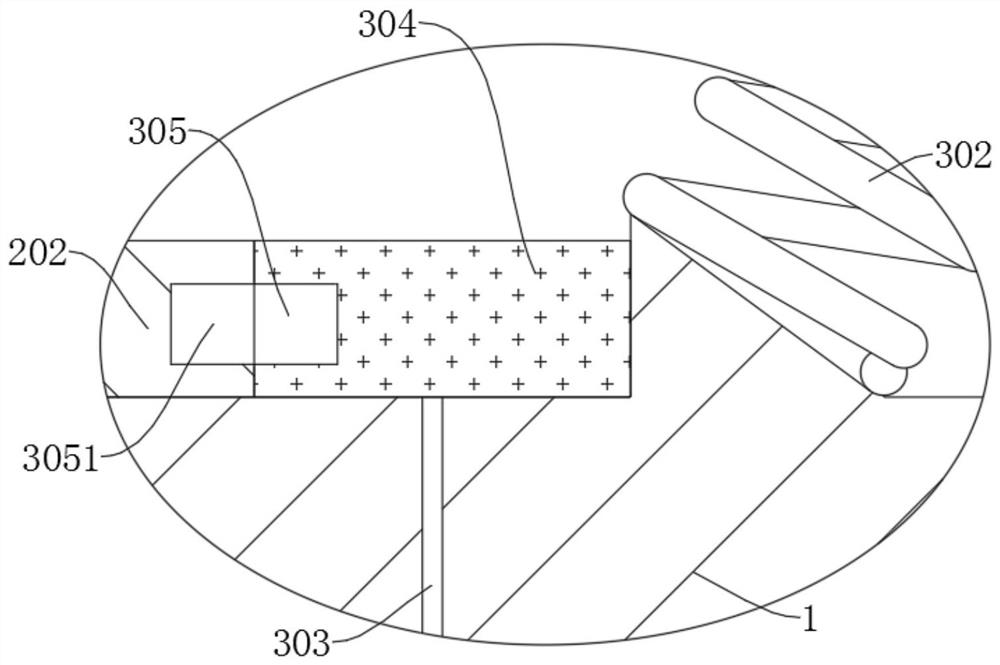

Turn-over throwing device for bedding

The invention provides a turn-over throwing device for bedding. The turn-over throwing device comprises a bottom supporting frame, a walking cart supporting frame, a turn-over throwing machine top cover, a lifting mechanism, a rake tooth roller mechanism, a roller driving mechanism and a walking cart driving mechanism; two walking guide rails are arranged at the two sides of the bottom supporting frame respectively, and the walking cart supporting frame is arranged on the walking guide rails and is in linkage with the walking cart driving mechanism to move along the walking guide rails; pural turn-over throwing rake teeth are arranged on the rake tooth roller mechanism; the turn-over throwing machine top cover is arranged on the top of the walking cart supporting frame, the rake tooth roller mechanism is hung on the turn-over throwing machine top cover, the lifting mechanism is used for driving the turn-over throwing machine top cover and the rake tooth roller mechanism to rise or fall, and the roller driving mechanism is used for driving the rake tooth roller mechanism to do rotating, turn-over throwing actions. The turn-over throwing device for bedding has the advantages that the weight of whole turn-over throwing rake teeth is reduced on the basis of ensuring strength, casting and cutting force on the bedding by the turn-over throwing rake teeth can be increased, the turn-over throwing effect is good, and the turn-over throwing efficiency is high.

Owner:福建省农科农业发展有限公司

Feed throwing device for outdoor poultry farming

InactiveCN113273518AGood throwing effectGood throwing abilityRotary stirring mixersTransportation and packagingPoultry farmerAgricultural engineering

The invention discloses a feed throwing device for outdoor poultry farming, and belongs to the technical field of poultry farming. The feed throwing device for outdoor poultry farming comprises a feed throwing box body, a driving motor, a throwing frame, a throwing spring and a clamping block, wherein the feed throwing box body is provided with a feed storage cavity, and a discharge port is formed in the lower end of the feed storage cavity; the driving motor is fixedly connected to the feed throwing box body, and the output end of the driving motor is fixedly connected with a cam; the throwing frame is rotationally connected to the feed throwing box body, and a discharging groove matched with the discharge port is formed in the throwing frame; the two ends of the throwing spring are fixedly connected to the throwing frame and the feed throwing box body respectively; and the clamping block is magnetically attached to the cam. Through magnetic attraction of the clamping block and the cam, when the clamping block and the cam are separated, throwing of the throwing frame is not subjected to pulling force of the cam, so that the throwing effect of the throwing frame is better, opening and closing of the discharge port are controlled in cooperation with magnetic attraction, feed waste can be prevented, meanwhile, through cooperation with a stirring shaft, feed stirring is facilitated, feed accumulation is prevented, and the throwing effect is improved.

Owner:萍乡市白竺和平农场

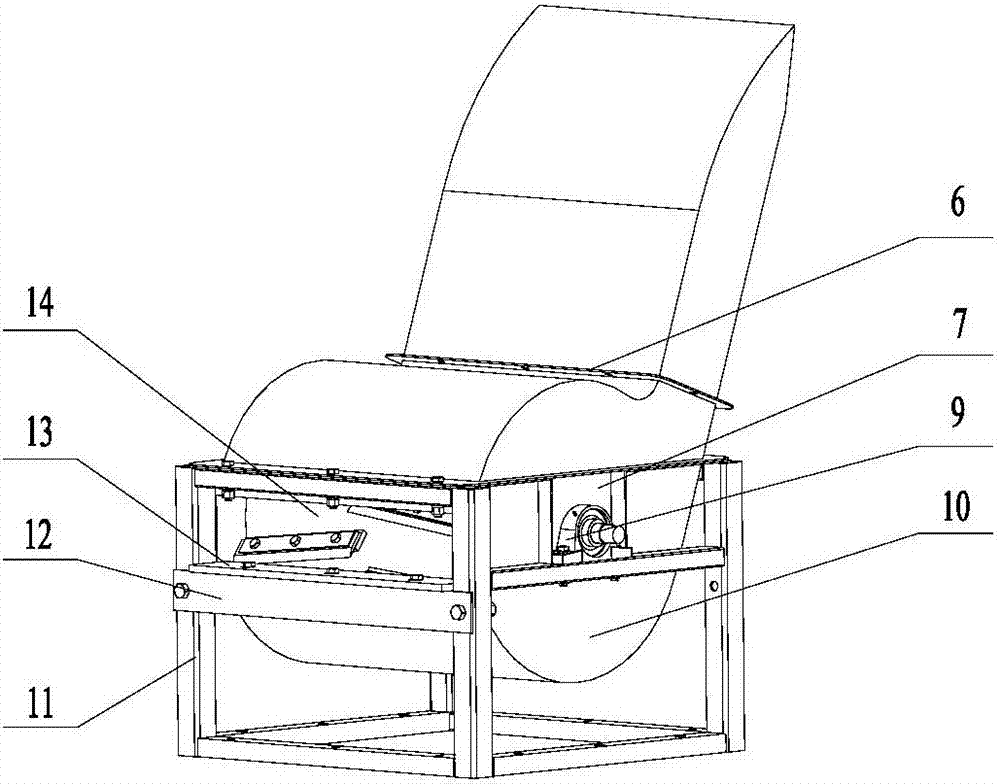

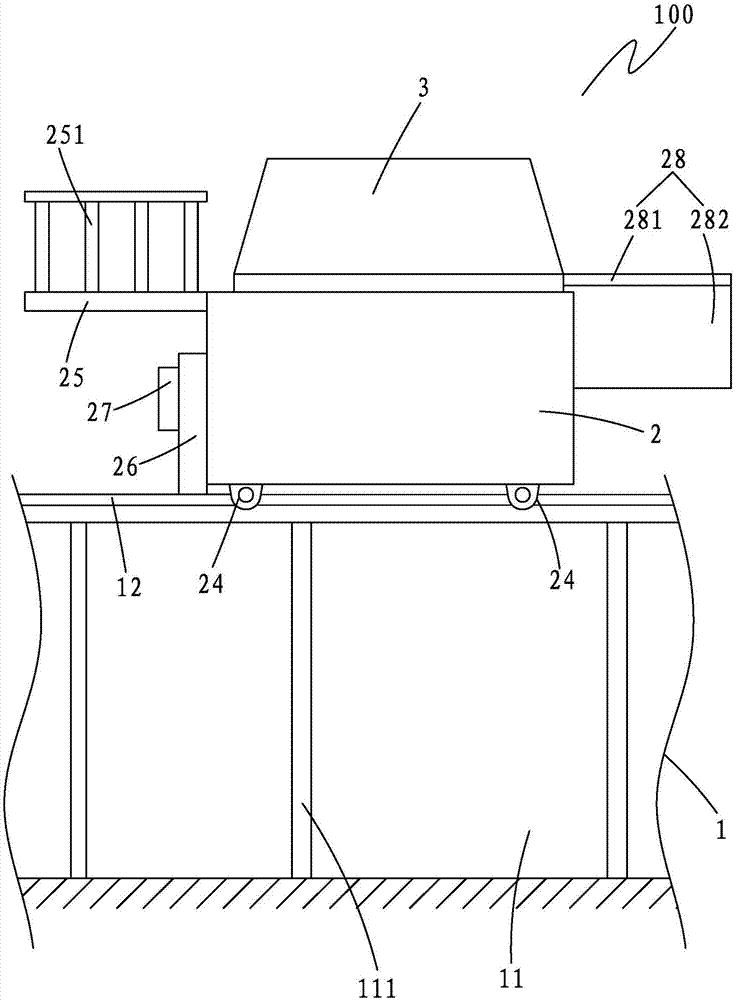

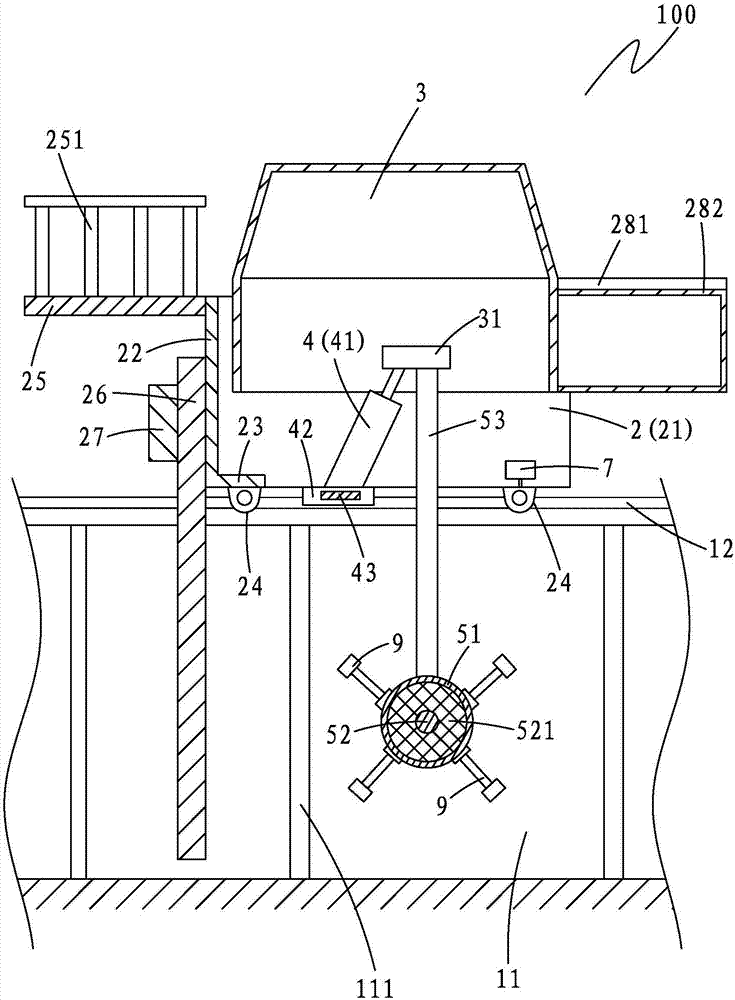

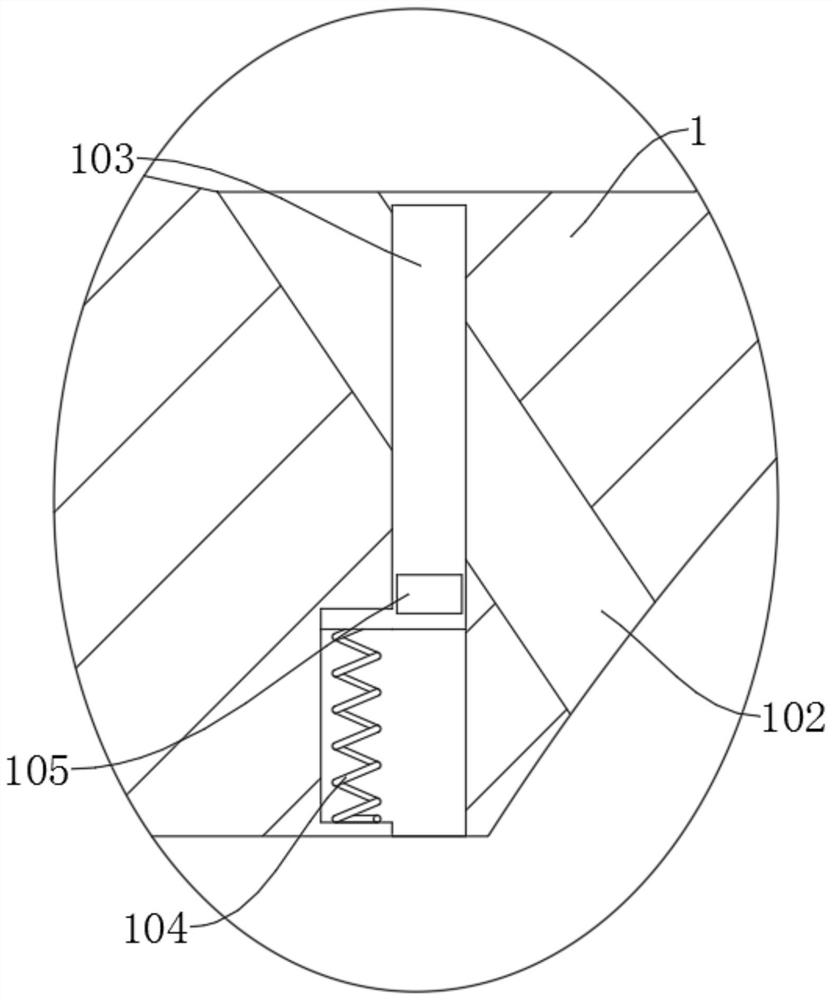

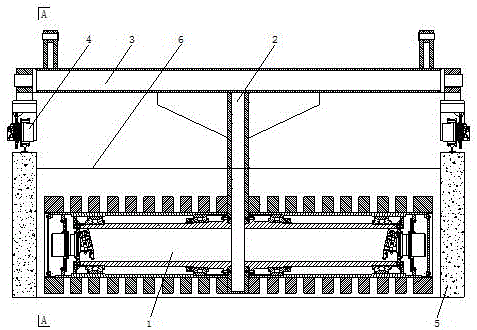

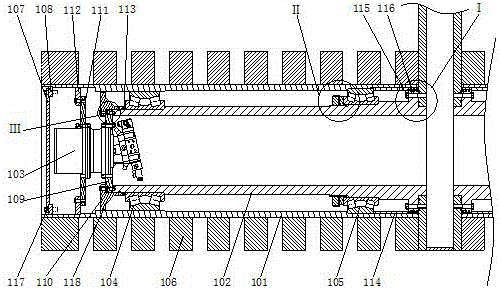

Groove type sludge turning-throwing machine and installation method of turning-throwing drums thereof

InactiveCN106747704AGuaranteed coaxialityImprove stress conditionClimate change adaptationSewage/sludge fertilisersSludgePulp and paper industry

The invention discloses a groove type sludge turning-throwing machine and an installation method of turning-throwing drums thereof. The groove type sludge turning-throwing machine comprises a machine body, wherein the machine body is at least formed by a machine frame, walking mechanisms, a turning-throwing arm and the two turning-throwing drums; the machine frame is supported by the walking mechanism at two sides; the upper part of the turning-throwing arm is connected with the middle part of the machine frame; two sides of the lower part of the turning-throwing arm are symmetrically connected with the two turning-throwing drums; each turning-throwing drum comprises a rotary drum, a support cylinder and a hydraulic driving device, each support cylinder is arranged in the corresponding rotary drum, the inner end of each support cylinder is fixedly connected with the turning-throwing arm, and a first bearing, a second bearing, a first bearing fixing device and a second bearing fixing device are connected between the inner wall of each rotary drum and the corresponding support cylinder; the power input end of each hydraulic driving device is connected with the corresponding support cylinder, and the power output end of each hydraulic driving device is connected with the corresponding rotary drum. The groove type sludge turning-throwing machine has the advantages that the structure is simplified, the reliability and turning-throwing efficiency of the drums of the turning-throwing machine are improved, the turning-throwing ability is enhanced, and the energy consumption is decreased.

Owner:CHONGQING HUAYU HEAVY IND ELECTROMECHANICAL CO LTD

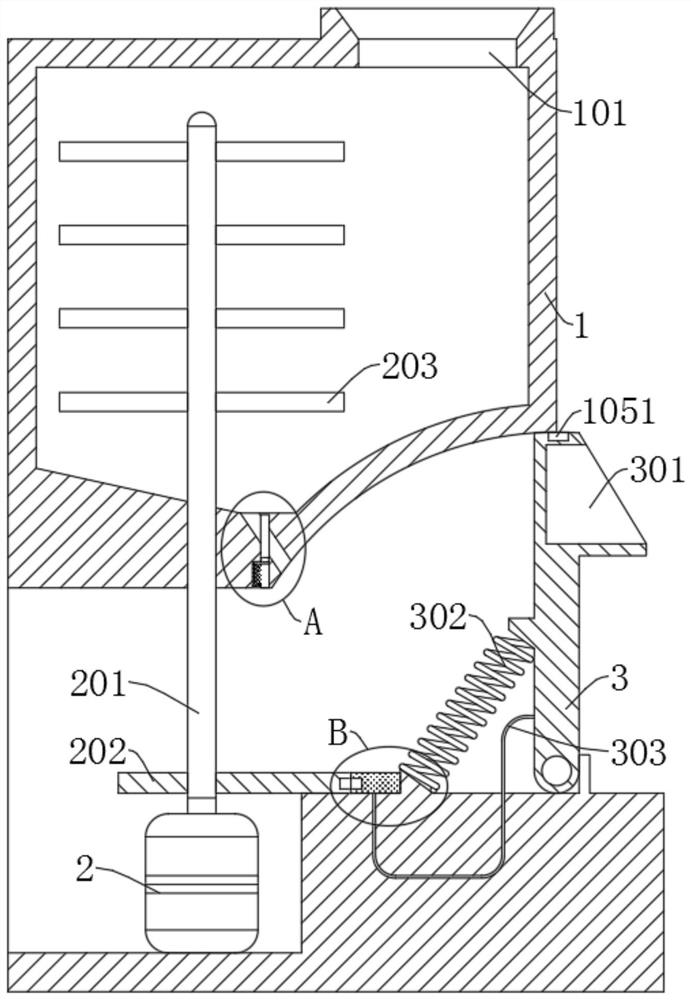

Grain throwing device and grain drying machine

ActiveCN110906706AThe spreading process is smoothSolve the problem of uneven accumulationDrying solid materials without heatDrying machines with non-progressive movementsEngineeringMechanical engineering

The invention provides a grain throwing device. The grain throwing device comprises a bottom plate and a guide component arranged on the bottom plate and used for guiding grains, wherein the guide component comprises a guide plate; the guide plate comprises an arc-shaped section and a straight section; an extension direction of the straight section is a tangential direction of the tail end of thearc-shaped section. The device is capable of uniformly throwing the grains and uniformly scattering the grains into a drying chamber, so that the problem that the grains are unevenly piled in the drying chamber can be effectively solved; the effective utilization rate of the space of the drying chamber and the grain drying efficiency are improved; the grains can be uniformly heated and are uniformin water content in the drying process; in addition, the invention also provides a grain drying machine comprising the grain throwing device; the grain drying machine is capable of uniformly drying the grains; the space utilization rate of the drying chamber is high; the drying quantity in unit time is high; the grains can be uniformly heated in the drying process; the water content of the grainstreated by the drying machine is uniform.

Owner:HUNAN NONGYOU MACHINERY GRP

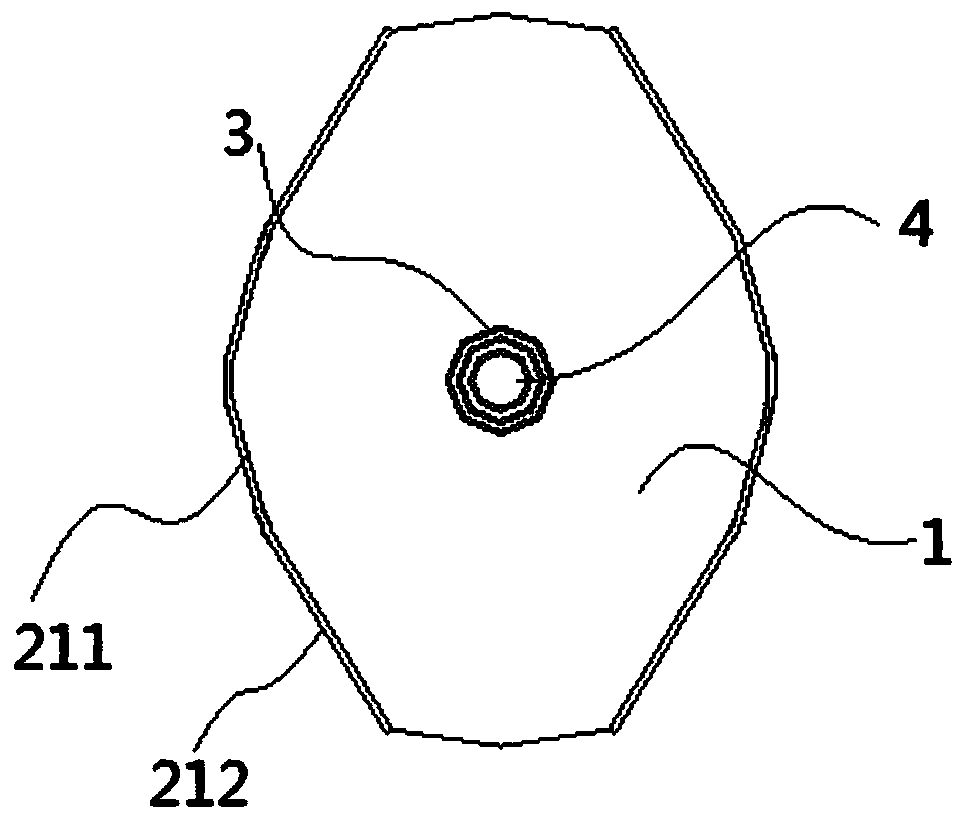

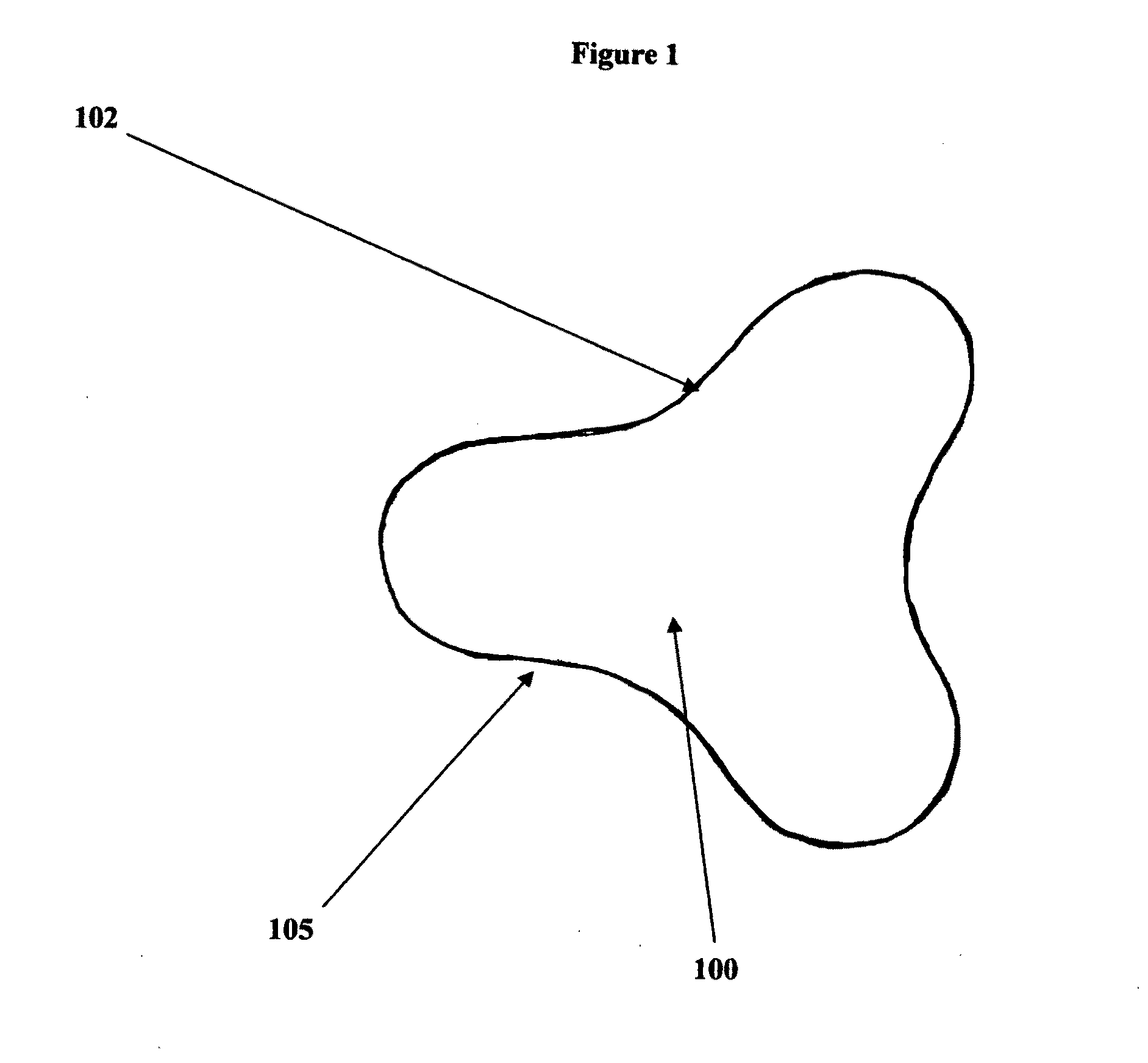

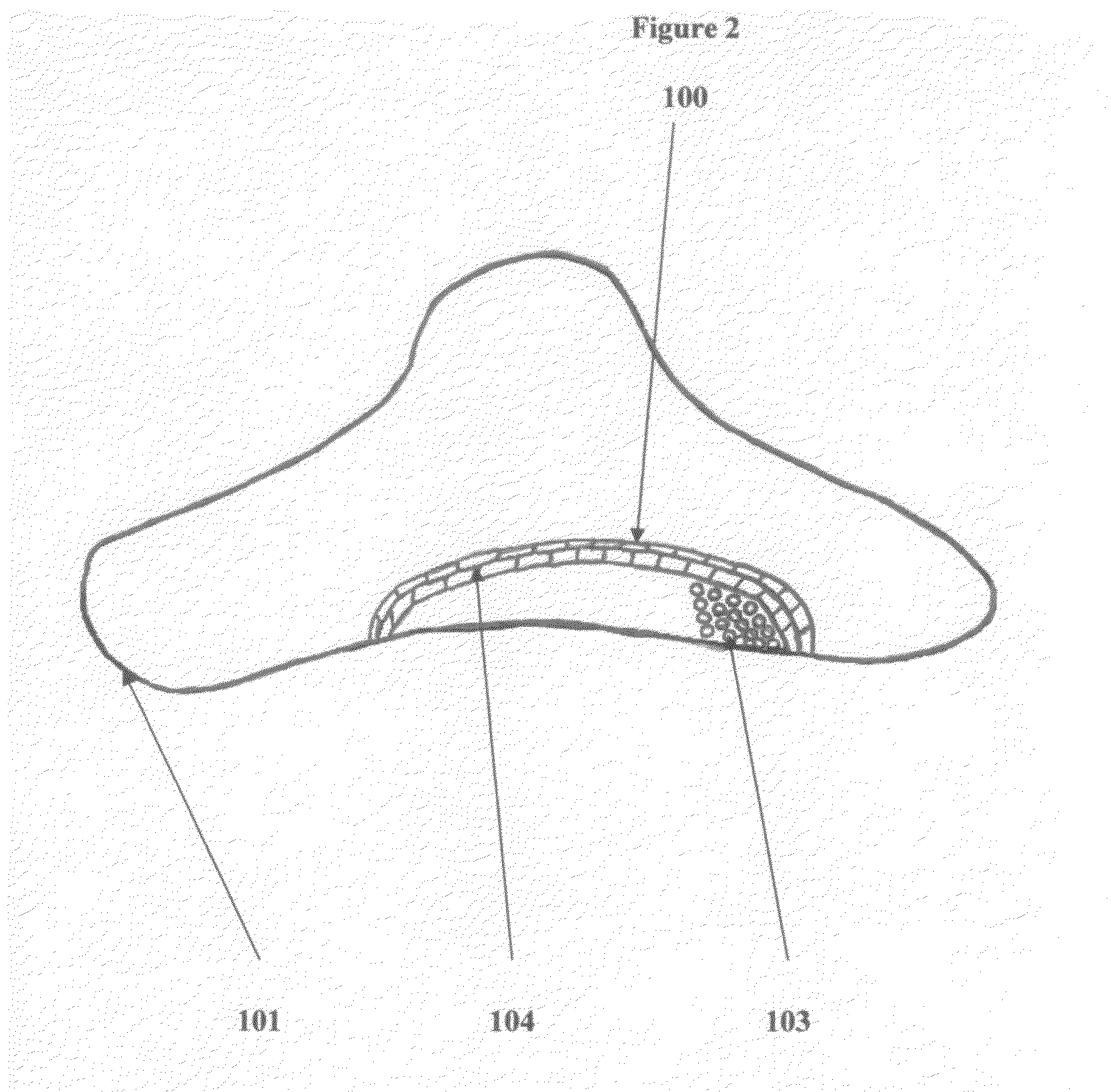

Skipping, skimming water toy

InactiveUS20110111670A1Improve securityIncrease centrifugal forceAquatic toysIsoetes triquetraRecreational use

A skipping or flying hydrodynamic water toy for children and dogs designed for recreational use upon and across a surface of water is provided. . . . The toy preferably is an equilateral triangle with concave sides and rounded vertices and includes a pliable body, or upper external layer of neoprene which is laminated with or without fabric or and has a natural buoyancy, and lower external layer of same material. The upper body preferably forms a relatively thin outer shell that extends laterally, through a smooth curve defining a peripheral region. The lower body is of similar design to provide minimum drag and maximum hydrodynamic performance. Since both external layers slope downwardly and upwardly respectively, they provide minimal toy contact with water thus increasing skipping characteristics and throwing distance. The interior cavity is filled with plastic pellets or some other material that can increase the buoyancy of the toy and adds weight to increase throwing distance. The upper and lower layers are sewn, melted or chemically adhered together to form a tight seal to prevent interior cavity material from escaping.

Owner:COMEAUX DALE MARK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com