Groove type sludge turning-throwing machine and installation method of turning-throwing drums thereof

A technology of turning drum and turning machine is applied in the directions of sewage/sludge fertilizer, organic fertilizer, fertilization device, etc., which can solve the problems of low turning efficiency, small turning ability and poor maintenance, so as to improve turning efficiency. , Avoid turning over dead corners, improve reliability and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

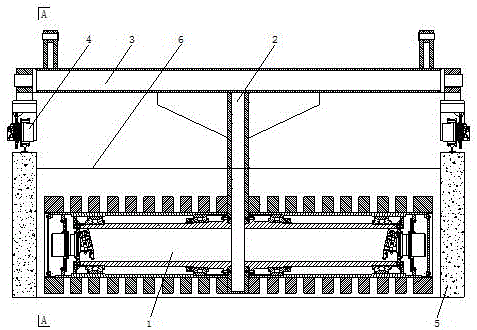

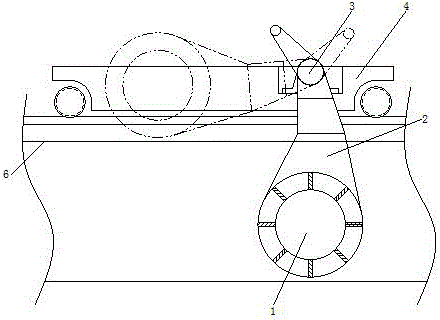

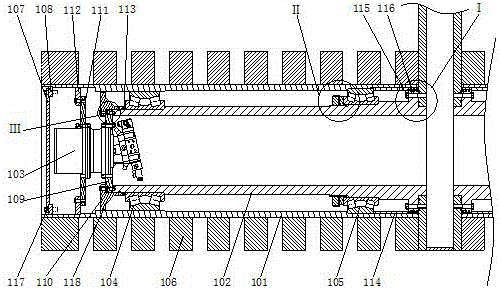

[0039] Such as Figure 1 to Figure 6 As shown, the present invention provides a trough sludge turning machine, comprising at least a frame 3, a walking mechanism 4, a turning arm 2 and two turning drums 1. The frame 3 consists of two The side walking mechanism 4 is supported, the upper part of the turning arm 2 is connected with the middle part of the frame 3, and the two sides of the lower part of the turning arm 2 are symmetrically connected with two turning and throwing drums 1; the turning and throwing drum 1 includes a rotating drum 101, a support cylinder 102 and a hydraulic drive device, the support cylinder 102 is arranged in the rotating drum 101 and its inner end is fixedly connected with the turning arm 2, and the first bearing 104 and the second bearing are connected between the inner wall of the rotating drum 101 and the supporti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com