Reinforcing mesh cage stone throwing device and use method

A steel mesh and mesh cage technology, which is applied in transportation and packaging, special-purpose ships, warships, etc., can solve problems affecting construction quality and construction efficiency, limited accuracy of riprap, uneven riprap, etc., and achieves easy fixed-point positioning control, Short-duration, easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

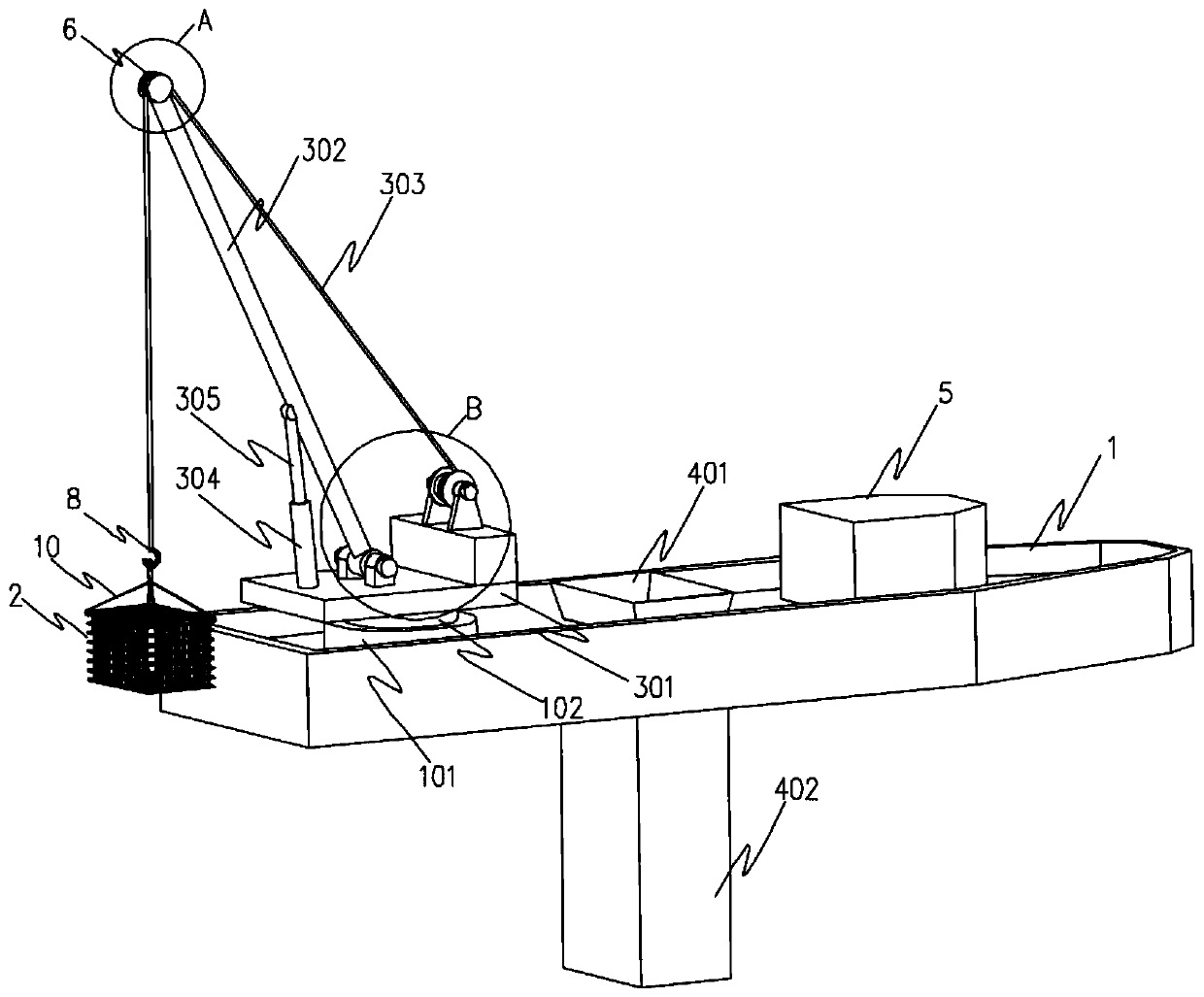

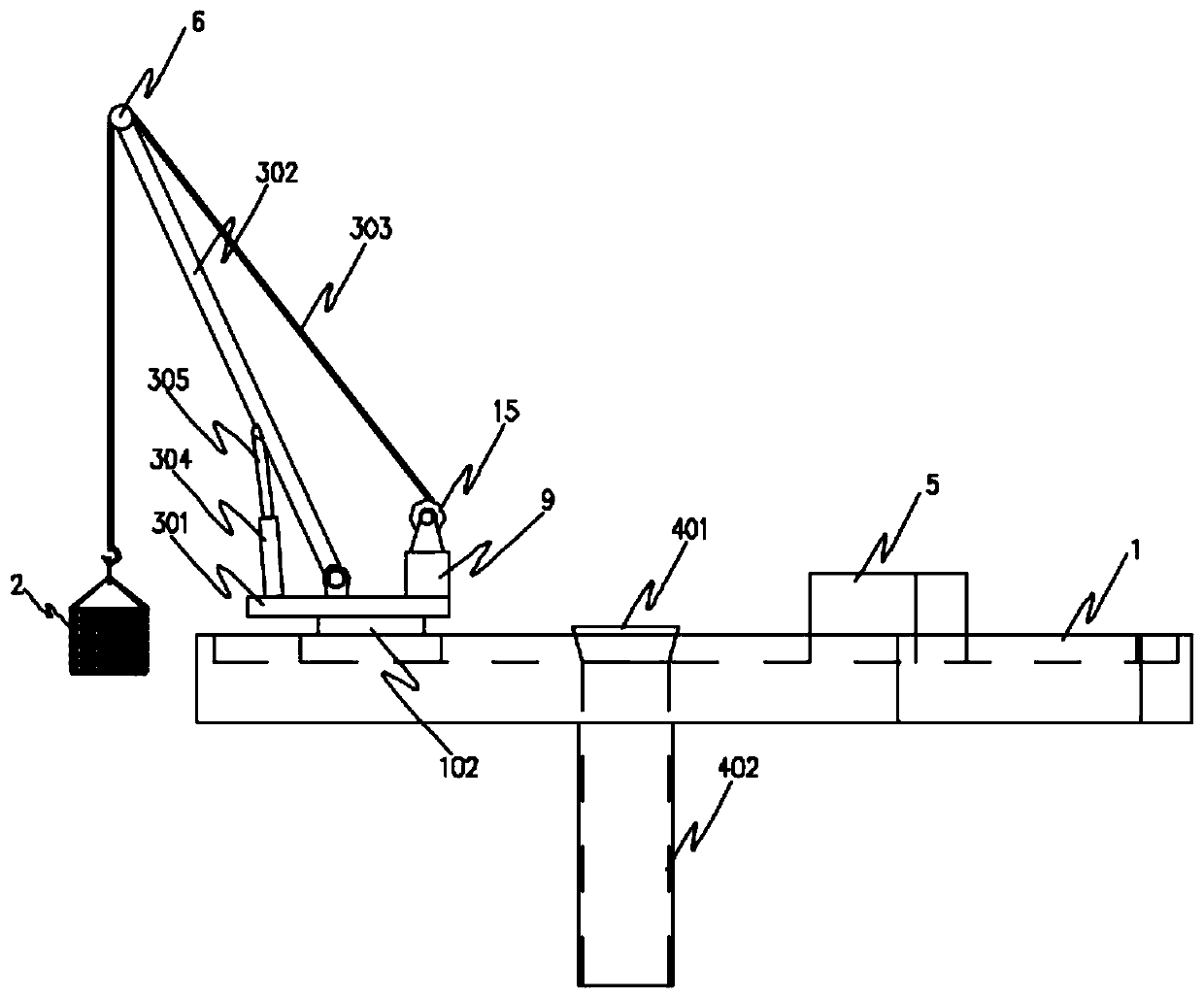

[0048] Such as figure 1 Shown, a kind of reinforced mesh cage riprap device comprises riprap ship 1, mesh cage 2, hoisting assembly, throwing assembly, and described riprap ship 1 is provided with cockpit 5, and described cockpit 5 is arranged on the Describe the front end of riprap boat 1.

[0049] Both the hoisting assembly and the throwing assembly are arranged on the rock-throwing ship 1, and the cage 2 is used to transport the thrown stones.

[0050] Such as figure 2 As shown, the throwing assembly includes a discharge port 401 and a discharge pipe 402 , the discharge port 401 is an inverted trapezoidal structure, and one end of the discharge pipe 402 is fixed at the lower end of the rock-throwing ship 1 .

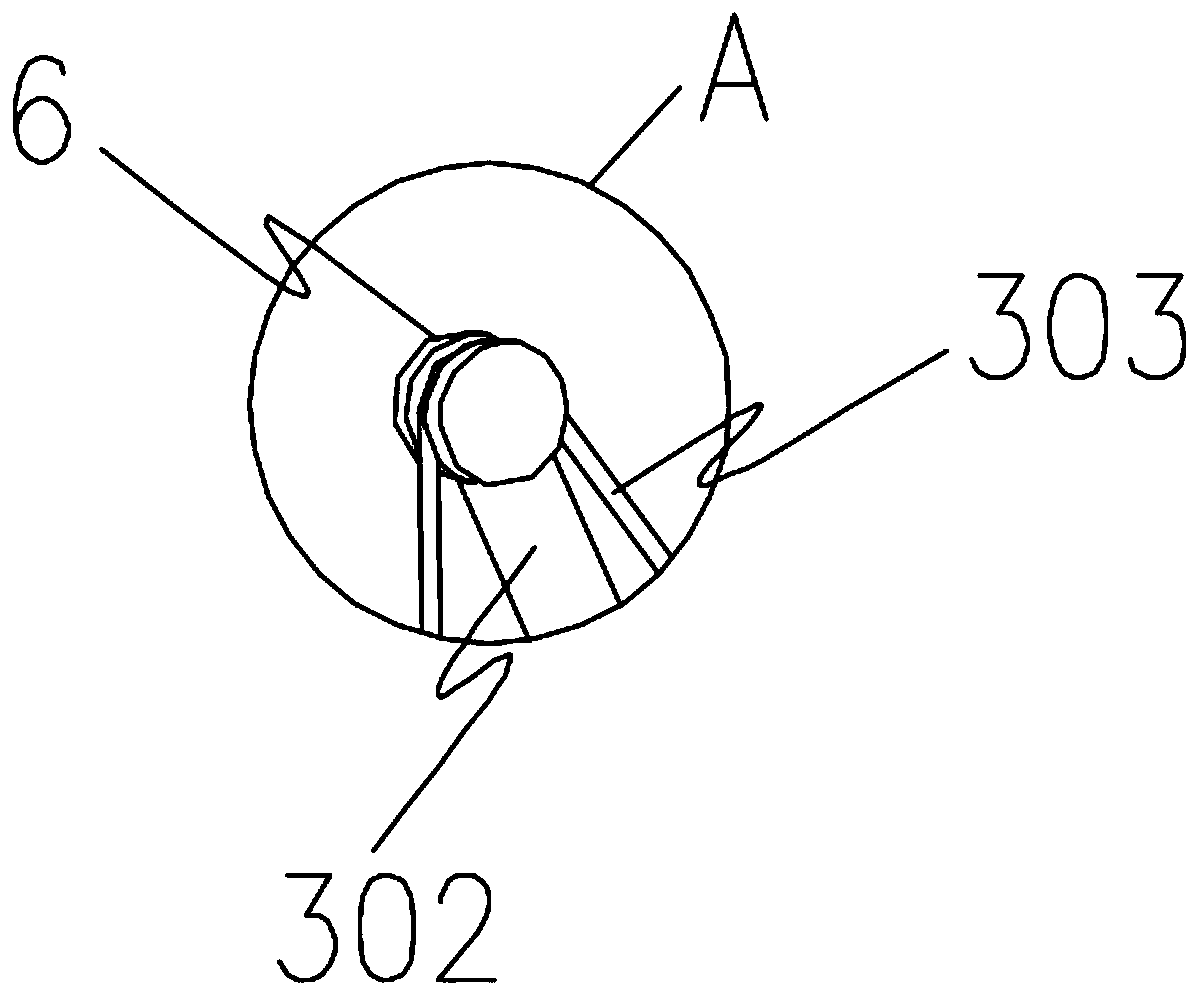

[0051] The hoisting assembly includes a mount 301, a hoisting long arm 302, a sling 303, a rope winding wheel 7, a first motor (not marked in the drawings), a hydraulic cylinder 304 and a telescopic rod 305. The hoisting long arm 302, hydraulic The cylinders 304 a...

Embodiment 2

[0064] Based on above-mentioned embodiment 1, a kind of using method of reinforced mesh cage riprap device comprises the following steps:

[0065] 101. Pre-made the construction grid diagram of the stone riprap, set the construction grid diagram, and mark the area to be placed and the area that has been placed with different colors, and throw stones one by one according to the construction grid diagram during construction;

[0066] 102. The riprap ship 1 travels to the throwing point, and the construction personnel lift the cage 2 through the hoisting assembly, that is, first fix it with the hook 8 and the hoisting ring 11, and then use the hydraulic cylinder 304 to control the telescopic rod 305 to realize the hoisting of the long arm 302 Rotation, at the same time, the rotation of the rope winding wheel 7 is controlled by the first motor to realize the retraction of the suspension rope 303;

[0067] 103. After step 102, the cage 2 is hoisted to the position of the feeding po...

Embodiment 3

[0071] Based on the above-mentioned embodiment 1, the similarities will not be repeated, and the difference is that, as Figure 6 and 7 As shown, the throwing assembly also includes a blanking wheel 403, a blanking rope 404, and a fixed ring 405. The blanking wheel 403 is arranged above the blanking port 401, and the blanking wheel 403 passes through the The fixing frame 406 is fixed on the riprap ship 1 .

[0072] Further, the number of the blanking wheels 403 is two, and the two blanking wheels 403 are respectively arranged on opposite sides of the blanking opening 401 .

[0073] Further, the fixed mount 406 is a rotating mechanism, and the fixed mount 406 can drive the feeding wheel 403 to rotate relative to the feeding opening 401, so as to avoid affecting the mesh cage 2 entering the feeding pipe 402 through the feeding opening 401 .

[0074] One end of the feeding rope 404 is fixed on the feeding wheel 403 , and the other end is connected to the fixing ring 405 , and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com