Turn-over throwing device for bedding

A technology of turning and throwing device and litter, which is applied to animal houses, applications, animal husbandry and other directions, can solve the problem that the turning and turning machine does not take dust-proof measures, increases the power output of the turning and turning machine, and the turning effect of the rake teeth is not ideal. and other problems, to achieve the effect of good flipping effect, compact structure and overall height reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

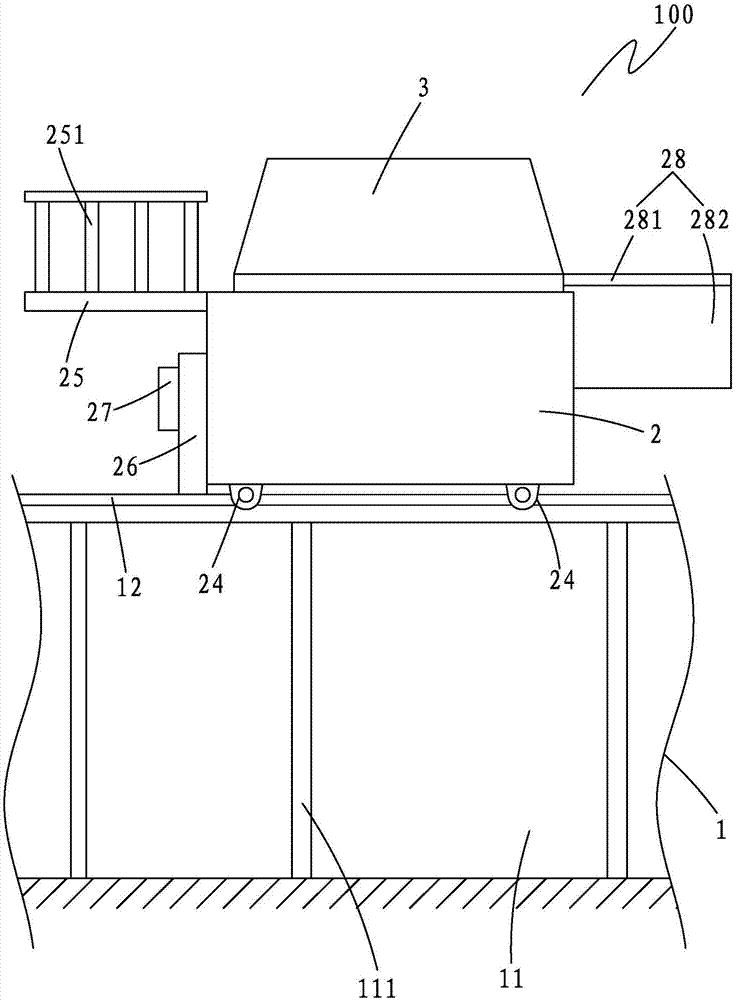

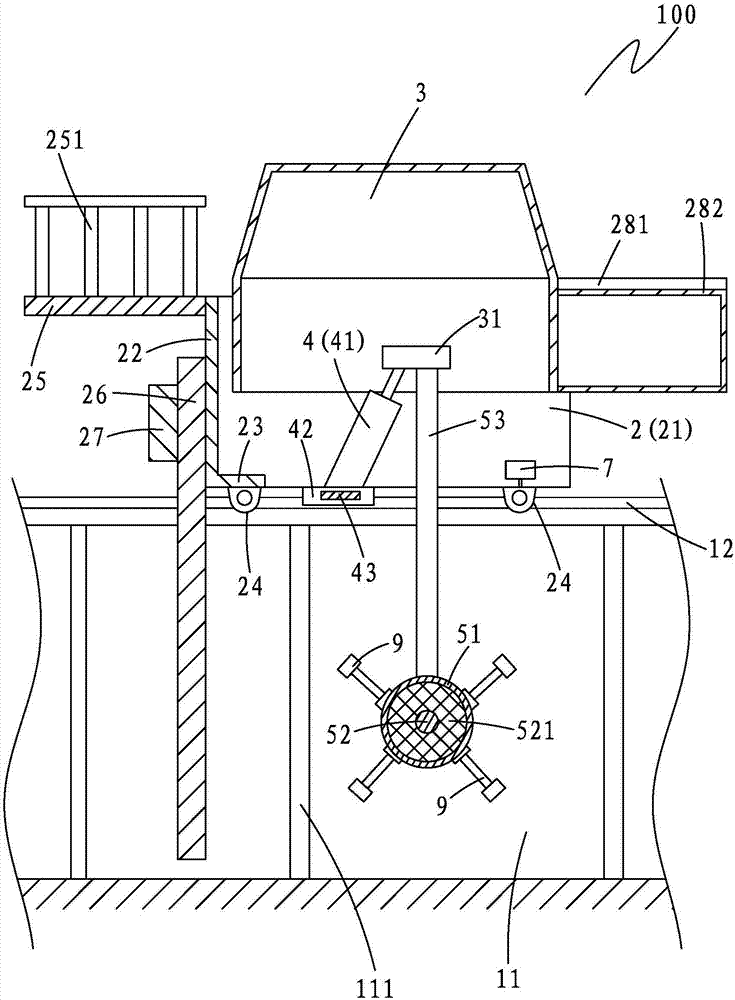

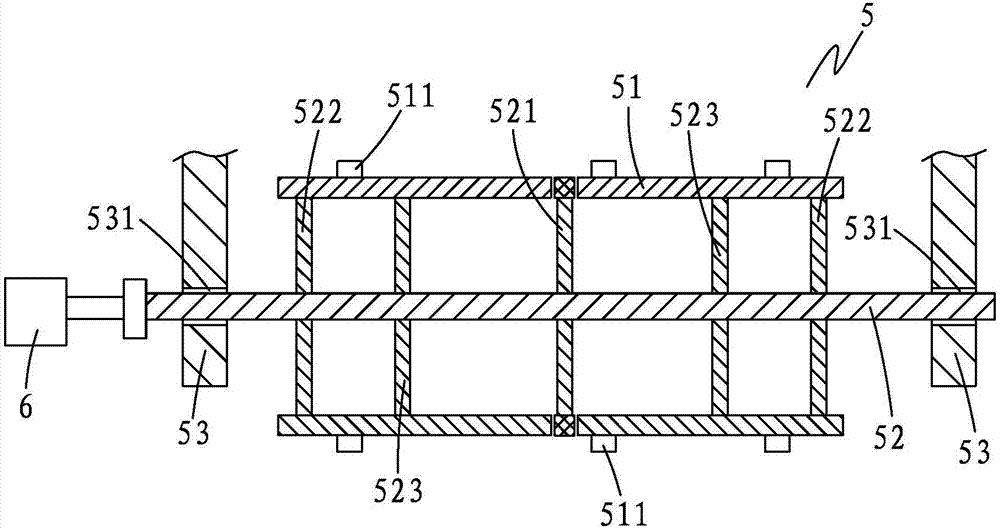

[0032] Please refer to Figure 1 to Figure 7 As shown, a preferred embodiment of a dunnage turning and throwing device 100 of the present invention, said turning and throwing device 100 includes a bottom support frame 1, a traveling support frame 2, a turning and throwing machine top cover 3, a lifting mechanism 4. A rake tooth roller mechanism 5, a roller driving mechanism 6, a trolley driving mechanism 7 and a control cabinet 8; both sides of the bottom support frame 1 are respectively provided with a walking guide rail 12, and the trolley support frame 2 placed on the walking guide rail 12; the traveling vehicle driving mechanism 7 is fixed on the traveling vehicle support frame 2, and the traveling vehicle supporting frame 2 is linked along the walking guide rail 12 through the traveling vehicle driving mechanism 7 Move; wherein, the bottom support frame 1 can be composed of two supporting walls 11, and in order to strengthen the supporting strength, several supporting col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com