Fertilizer turner equipment

A turning and throwing machine, fertilizer technology, applied in the direction of organic fertilizer equipment, organic fertilizer preparation, organic fertilizer, etc., can solve the problems of high cost, low efficiency, insufficient turning and throwing strength, etc., to achieve high power consumption, high efficiency, turning good throwing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to understand the above-mentioned purpose, features and advantages of the present invention more clearly, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific implementation methods.

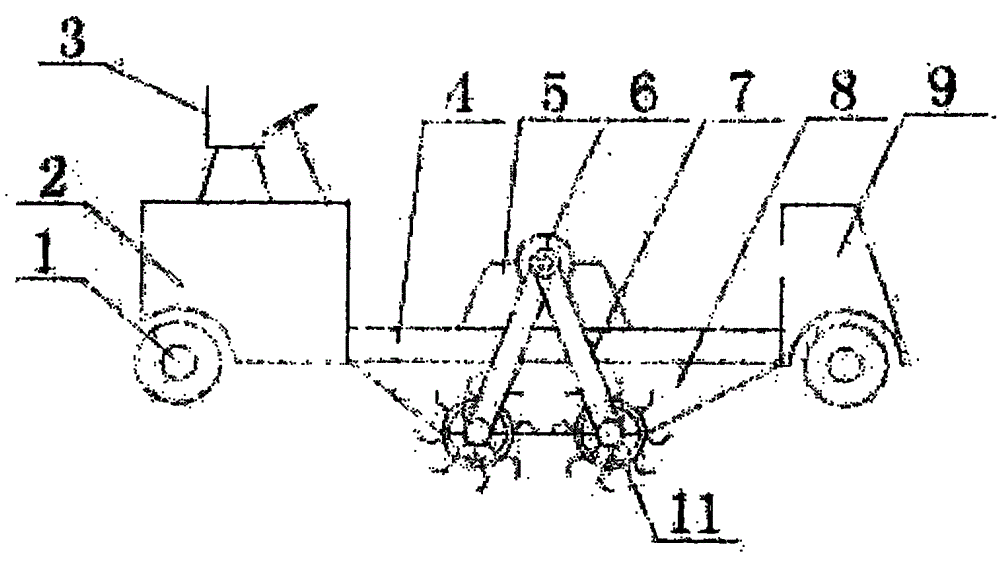

[0020] The manufacturing method of the fertilizer cooler of the present invention comprises: traveling wheels, engine case, operating table, crossbeam, motor table, motor, bracket, guard plate, side table, turning and throwing wheel.

[0021] A. The box is welded with channel steel, and the metal plate on the upper surface of the box is welded. There are multiple rotating shafts installed on the upper surface of the box. The motor is connected by a belt transmission between the rotating shafts at the ends, and then drives the conveyor belt to move;

[0022] B. Install a feed hopper on the upper part of one end of the box, and a discharge pipe is fixedly installed under the feed hopper, and the discharge pipe is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com