Take-up reel and cable dividing machine using take-up reel

A technology of take-up reel and dividing machine, which is applied in the direction of conveying filamentous materials, thin material handling, transportation and packaging, etc., can solve the problems of cumbersome assembly and disassembly process, and achieve long service life, simple locking structure and mechanical failure. low rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

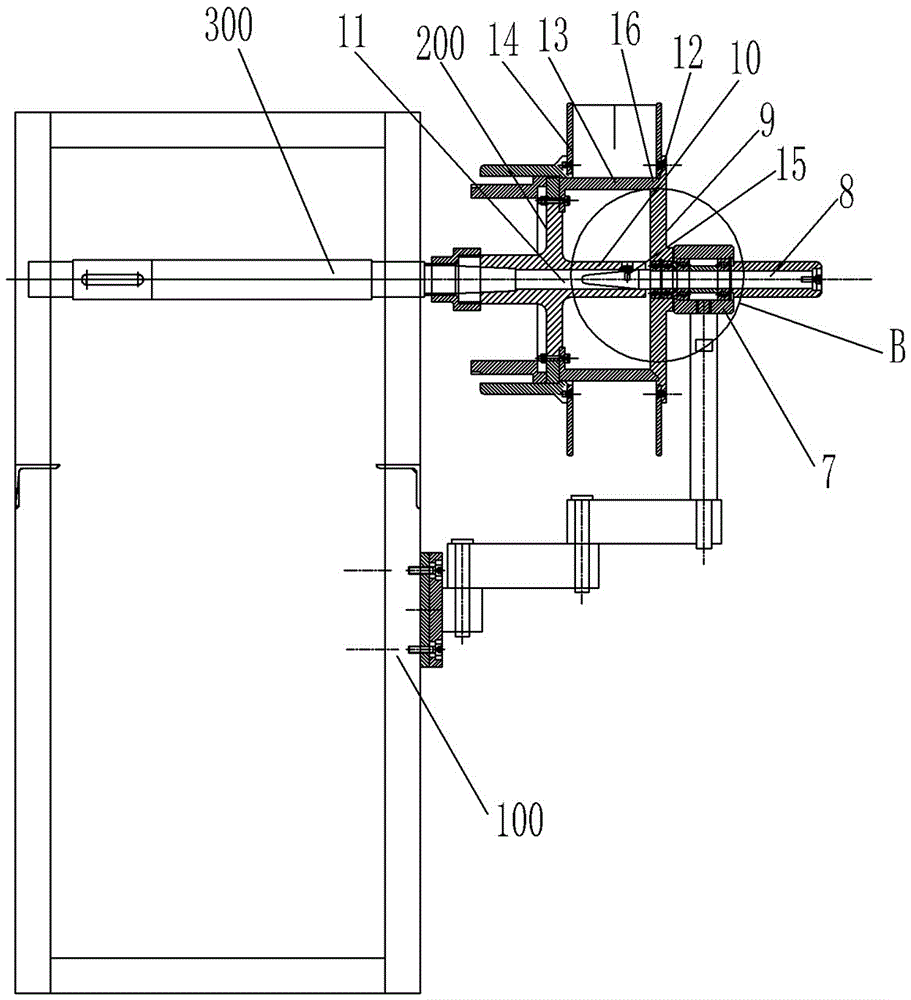

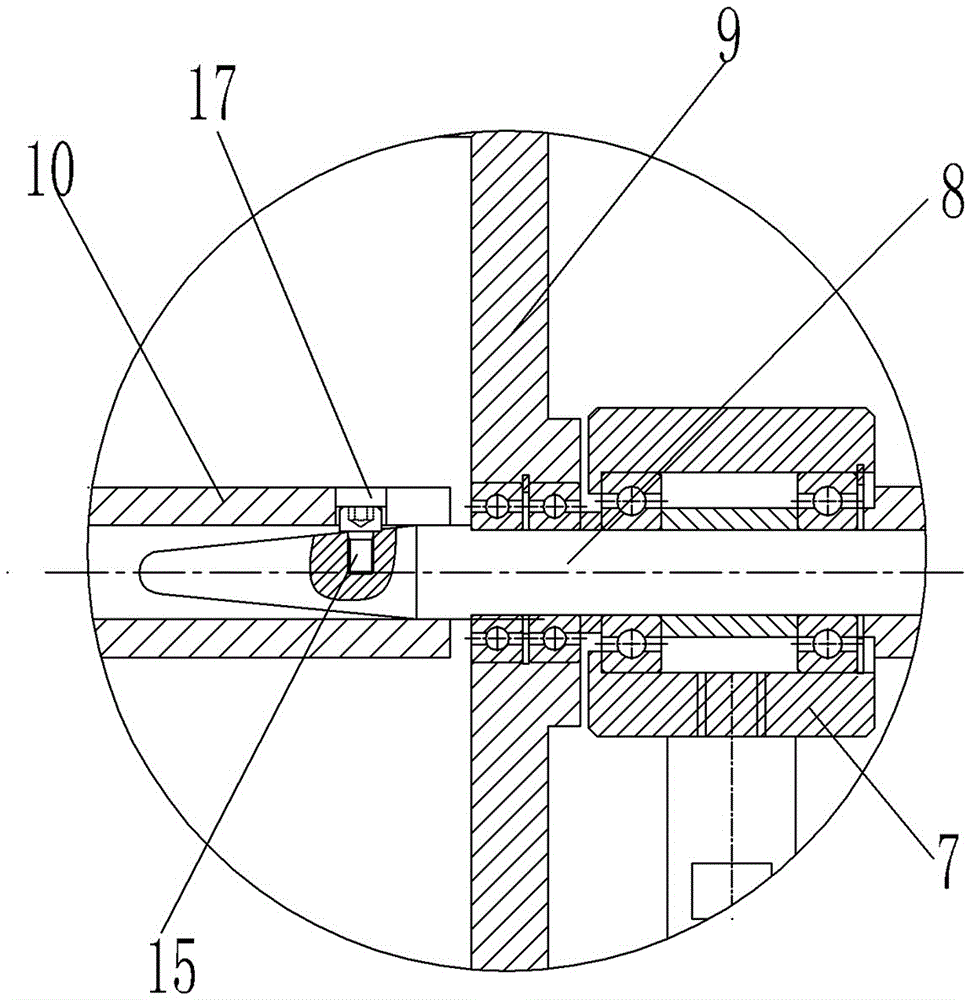

[0024] Such as Figure 1 to Figure 3 As shown, an embodiment of a cable splitter, the cable splitter in this embodiment includes a wire pay-off device (not shown in the figure) and a wire take-up device, and the wire take-up device includes a wire pay-off device arranged on the mounting frame 100 Reel 200, where the pay-off reel 200 includes a bobbin 13 arranged axially along the horizontal direction, the bobbin 13 is driven to rotate by a drive shaft 300, and two baffles are respectively provided at both ends of the bobbin 13 in the axial direction , the two baffles include a fixed baffle 14 on the inside and a movable baffle 9 on the outside.

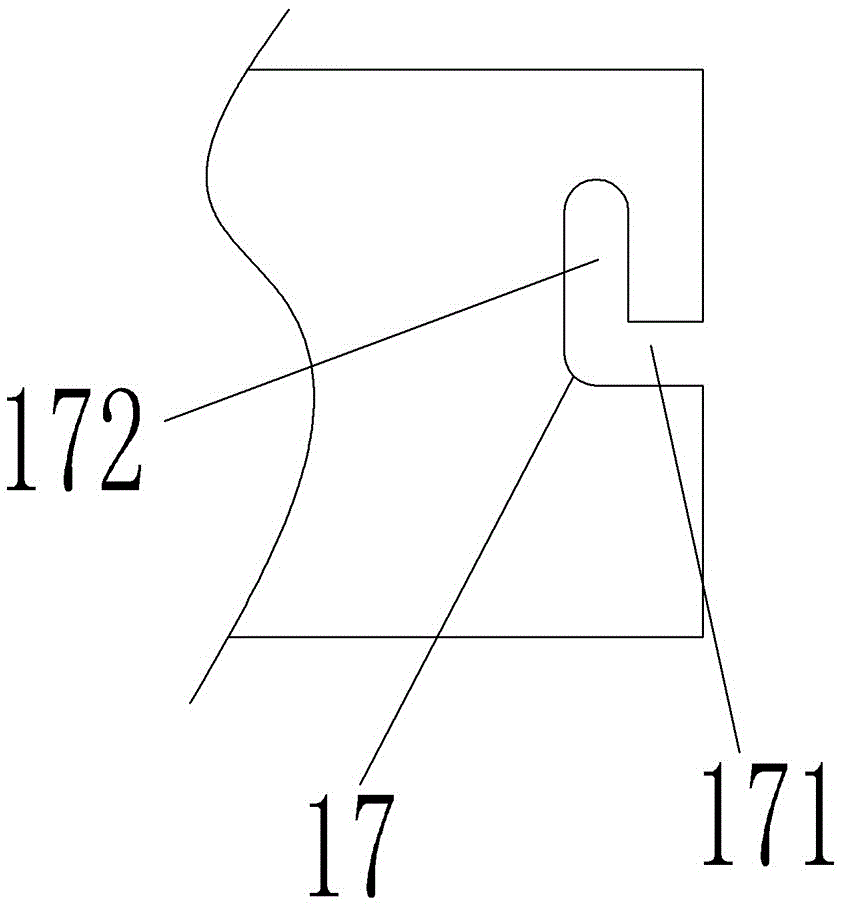

[0025] In this embodiment, the movable baffle 9 is installed on the support shaft 8 through the rotating sleeve of the bearing structure, and the movable baffle 9 is relatively fixedly assembled with the support shaft 8 in the axial direction of the support shaft 8. In this way, the movable baffle and the support The shaft is relativ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com