Booster braking device for automobile

A technology of automobile braking and braking force, applied in the direction of braking transmission, brakes, vehicle components, etc., can solve the problems of driving safety impact, failure to provide braking boost, and braking system cannot obtain braking boost, etc., to achieve flexible The effect of simple and direct control and mechanical machinery and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

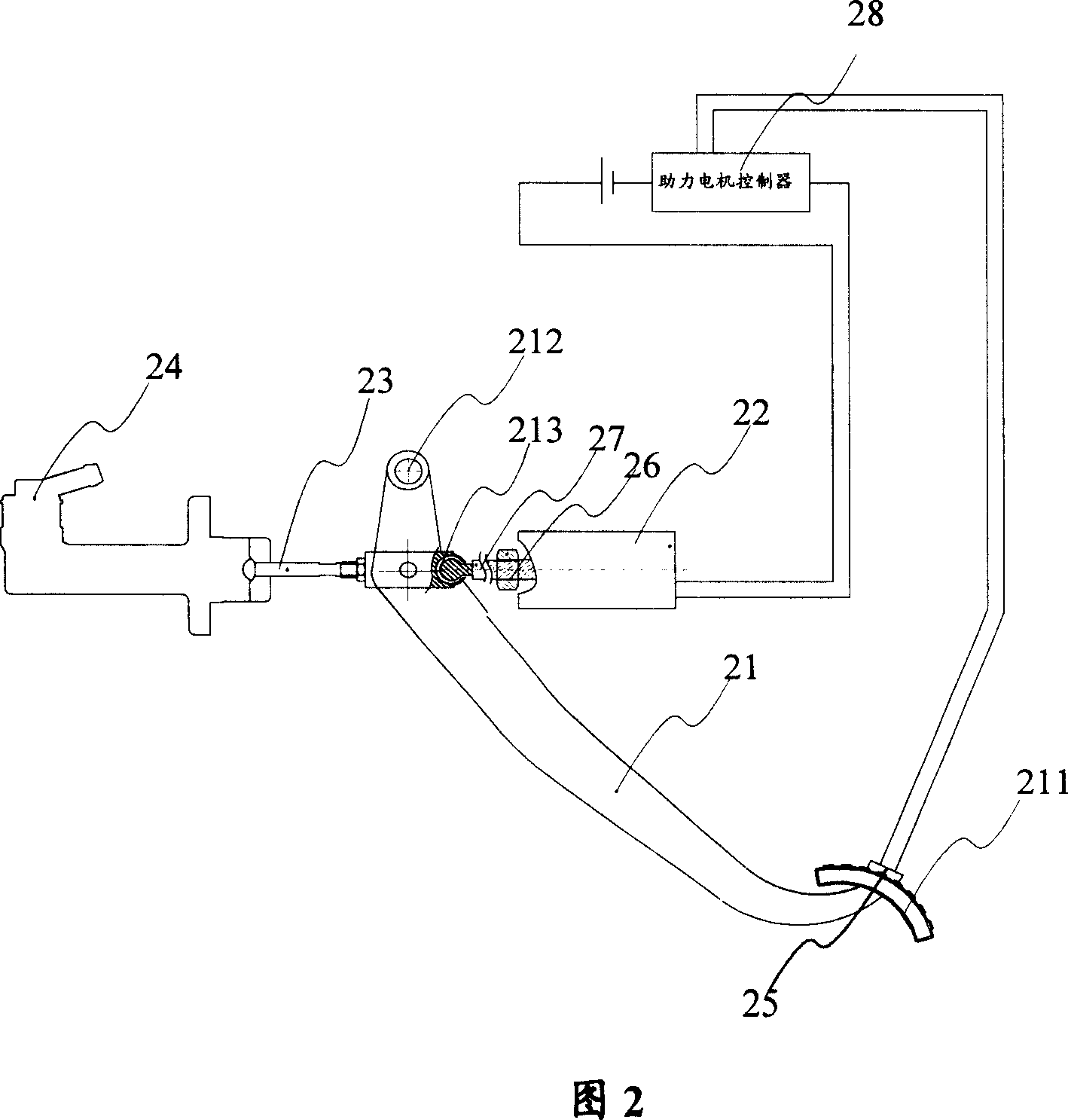

[0030] Please refer to FIG. 2 , which is a structural principle diagram of the first embodiment of the present invention.

[0031] As shown in FIG. 2 , the automobile brake booster system includes a brake pedal 21 , a booster motor 22 , a brake master cylinder 24 , a pressure sensor 25 and a booster motor controller 28 .

[0032] One end of the brake pedal 21 is a foot pedal 211 for receiving the operating force, and the other end is a fixed rotating shaft 212; the brake pedal 21 also has an output end 213, which is hinged with the brake master cylinder push rod 23. When the pedal 212 of the moving pedal 21 is energized, its output end 213 can rotate around the fixed rotating shaft 212, and energizes on the push rod 23 of the brake master cylinder.

[0033] The rotating shaft of the booster motor 22 is fixedly connected with the nut 26 , and meanwhile, the nut 26 cooperates with the lead screw 27 as a screw pair. Therefore, when the booster motor 22 rotates, the nut 26 also r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com