Prestress hole channel grouting quality control method based on double parameters of flow and density

A tunnel grouting and prestressing technology, which is applied in the erection/assembly of bridges, bridges, buildings, etc., can solve problems such as bleeding, not dense grouting, and hidden dangers in the project, and achieve high measurement accuracy, strong anti-interference, highly operable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

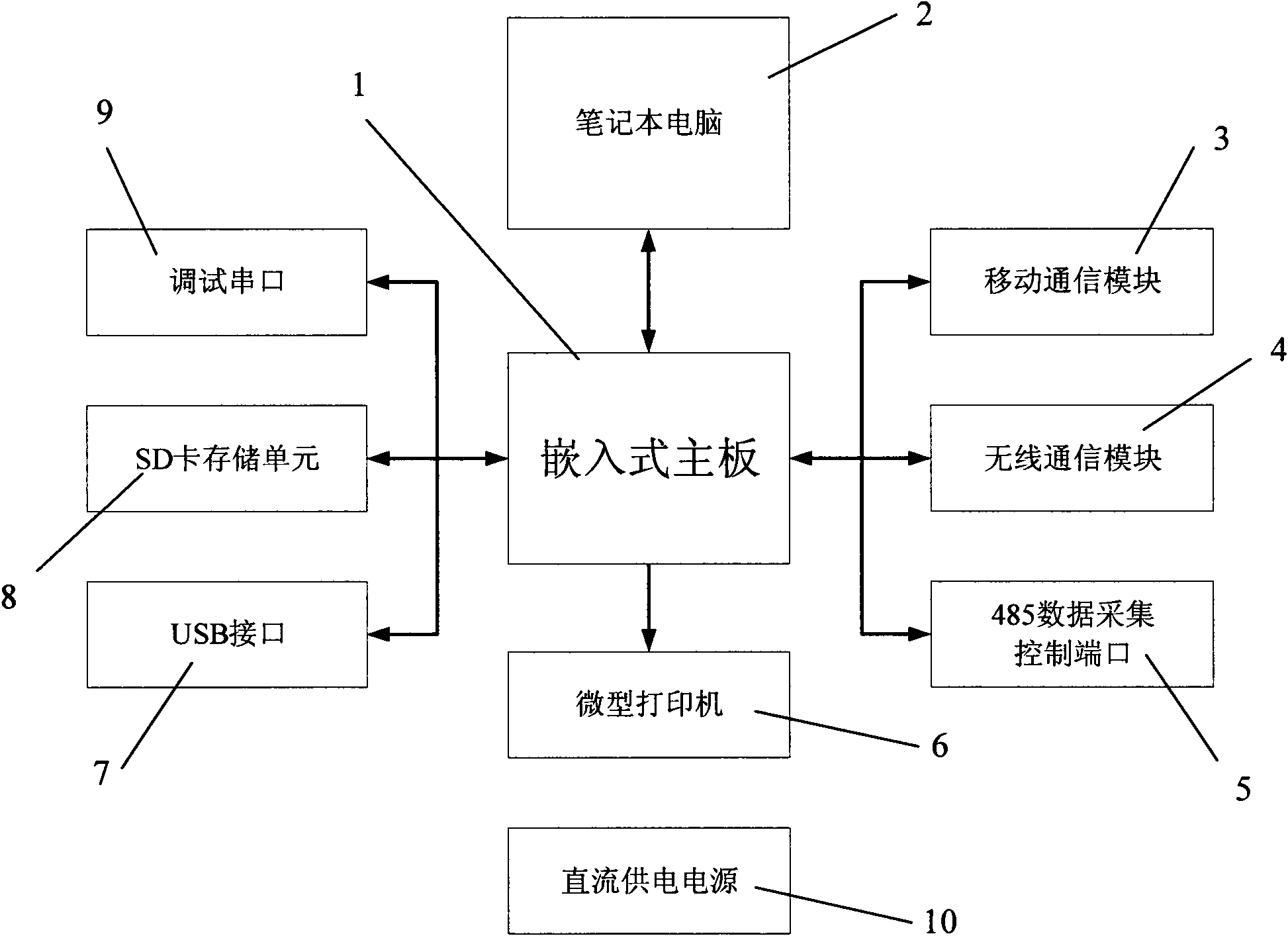

[0020] The present invention is further explained as follows with reference to accompanying drawing in conjunction with specific embodiment:

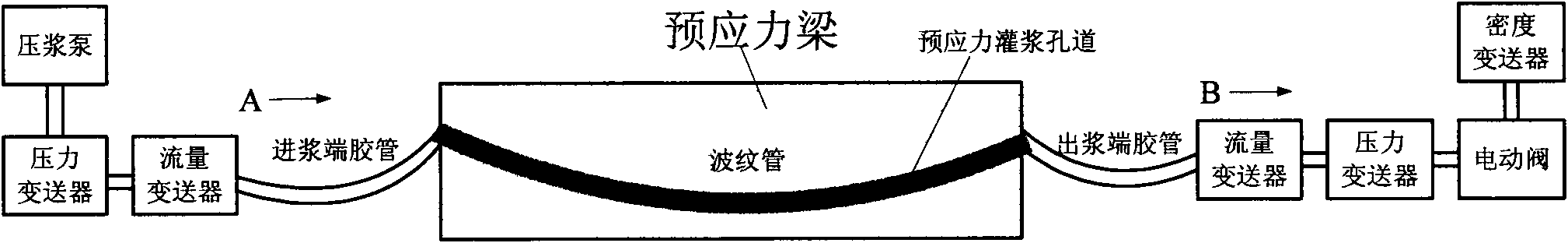

[0021] For the schematic diagram of grouting construction of bridge prestressed tunnel, please refer to the attached figure 1 A quality control method for bridge prestressed tunnel grouting based on the double parameters of flow rate and density. and the density transmitter, by judging the start time t of the screen slurry pressure holding k , to ensure the quality of prestressed channel grouting.

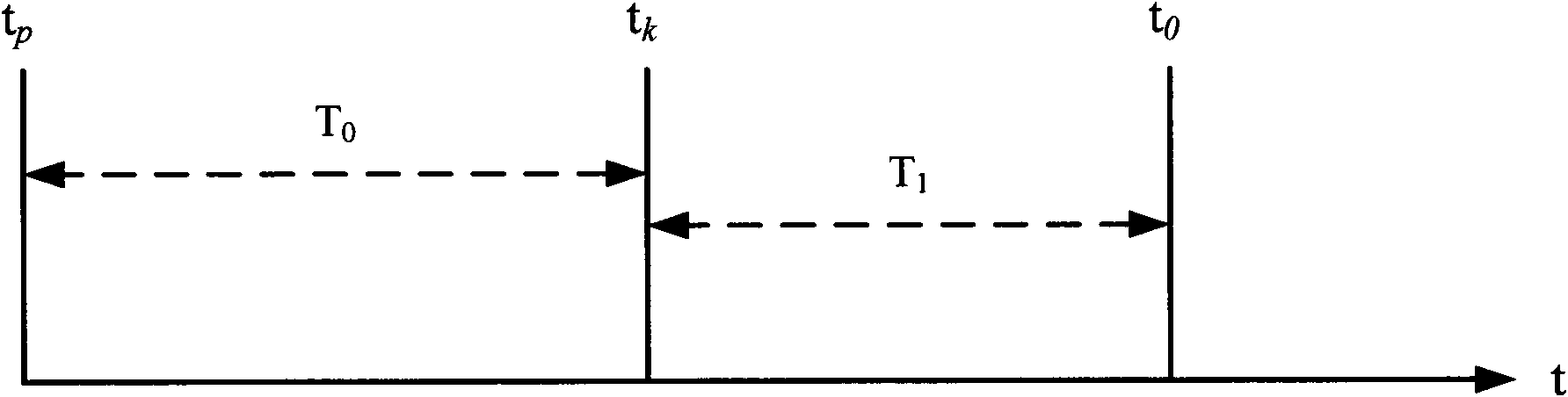

[0022] For the sequence diagram of the construction status of bridge prestressed channel grouting and grouting and pressure holding, please refer to the attached figure 2 , t in the figure p is the start time of grouting, at this time, start the grouting pump at the end A of the grouting end, t k It is the time to keep the pressure of the screen slurry, at this moment, close the electric valve at the end B of the slurry end, t p to t ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com