Half-wet method slag processing system and method

A treatment system and treatment method technology, applied in the semi-wet slag treatment system and treatment field, can solve the problems of high reprocessing cost of slag by-products, large amount of water resources, and difficulty in heat energy recovery, etc., and achieve low mechanical failure rate and active quality Good, even cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The specific implementation manner of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific examples.

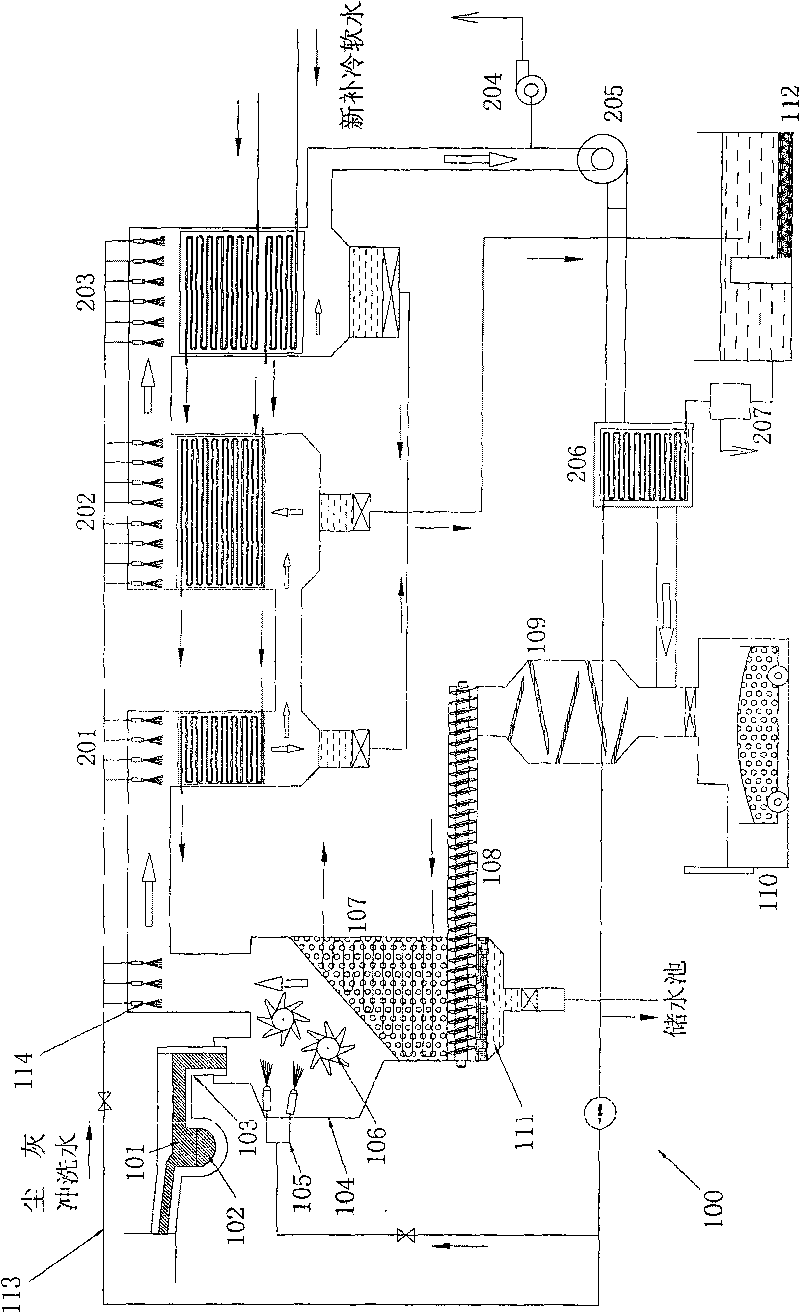

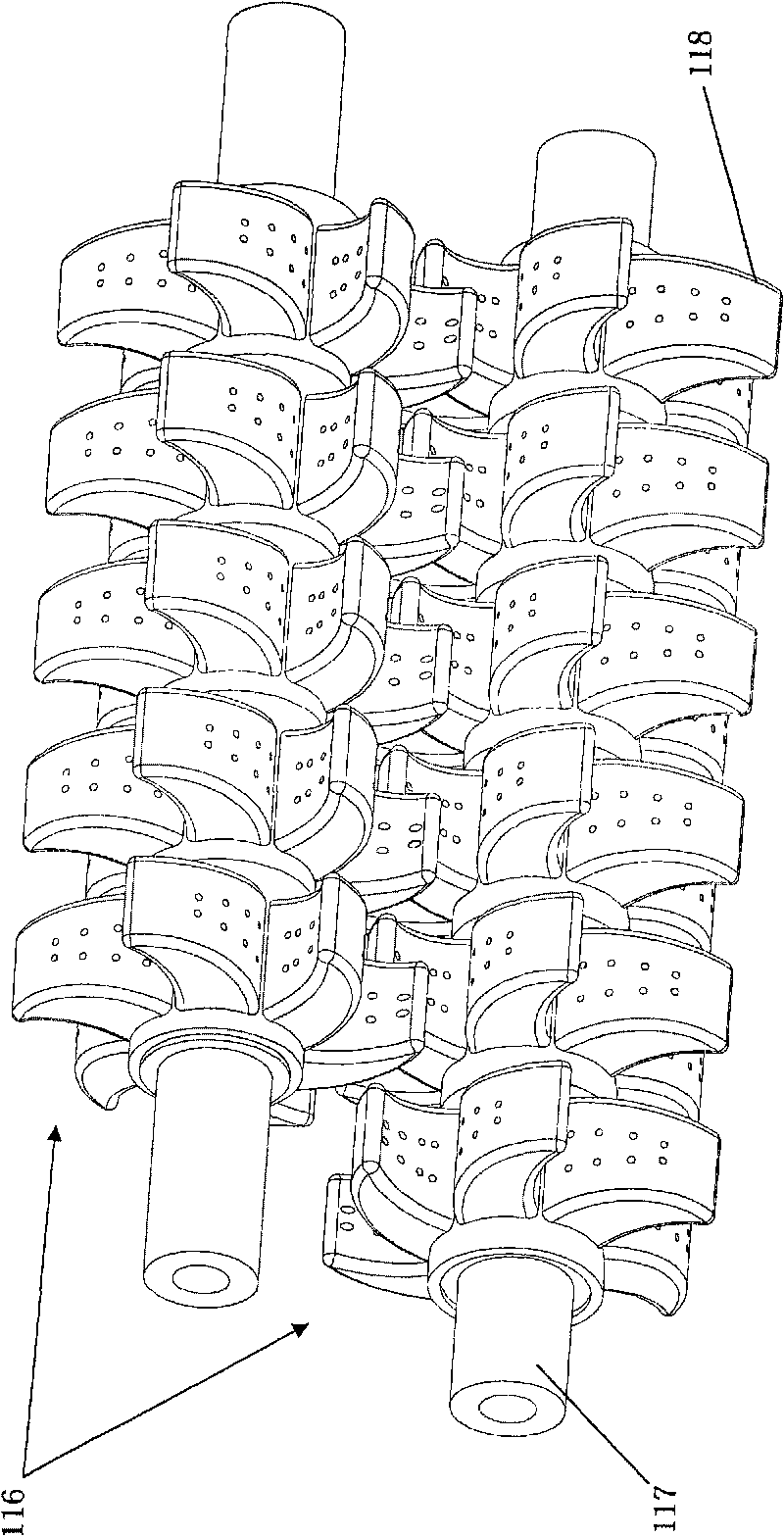

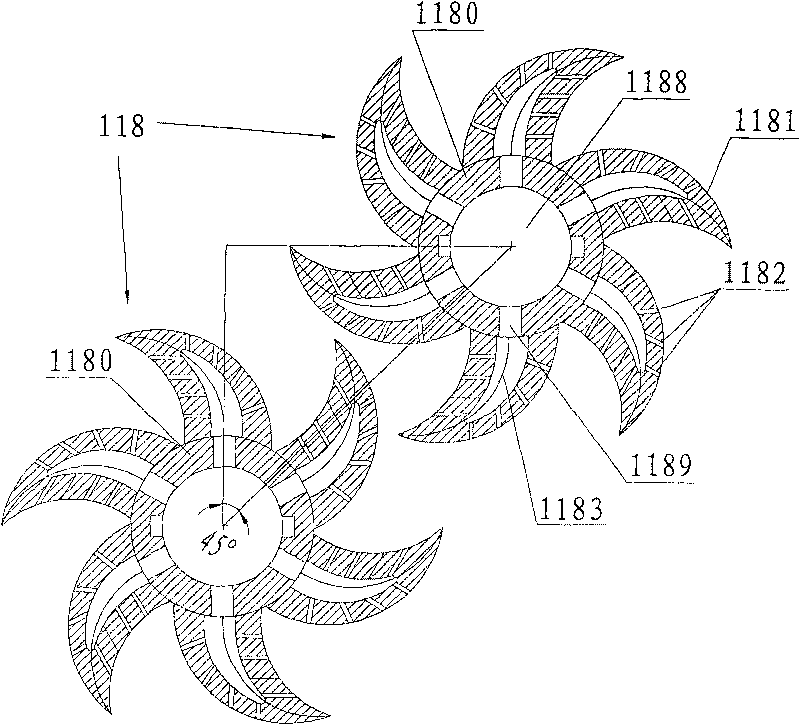

[0050] The present invention proposes a semi-wet slag processing system, which includes a slag buffer bin, a high-pressure gas mist nozzle, and a crushing device capable of high-speed rotation. The upper part of the slag buffer bin has a high-temperature liquid slag inlet, and the The slag inlet is connected to the slag outlet of the blast furnace; the high-pressure gas mist nozzle and the crushing device are arranged in the slag buffer bin and located below the slag inlet, and the high-pressure gas mist nozzle sprays the high-pressure gas mist in the direction of the crushing device to impact and cool the blast furnace The liquid slag is further mechanically crushed by a crushing device, and processed into raw materials for making cement. This system is suitable for the production process of blast f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com