Under-actuated rope-drive mechanical arm

A manipulator, underactuated technology, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of increase of drive motors, reducers and other related parts, mechanical failure rate and cost increase, etc., to reduce the mechanical failure rate. , the structure is simple and reliable, the effect of convenient control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

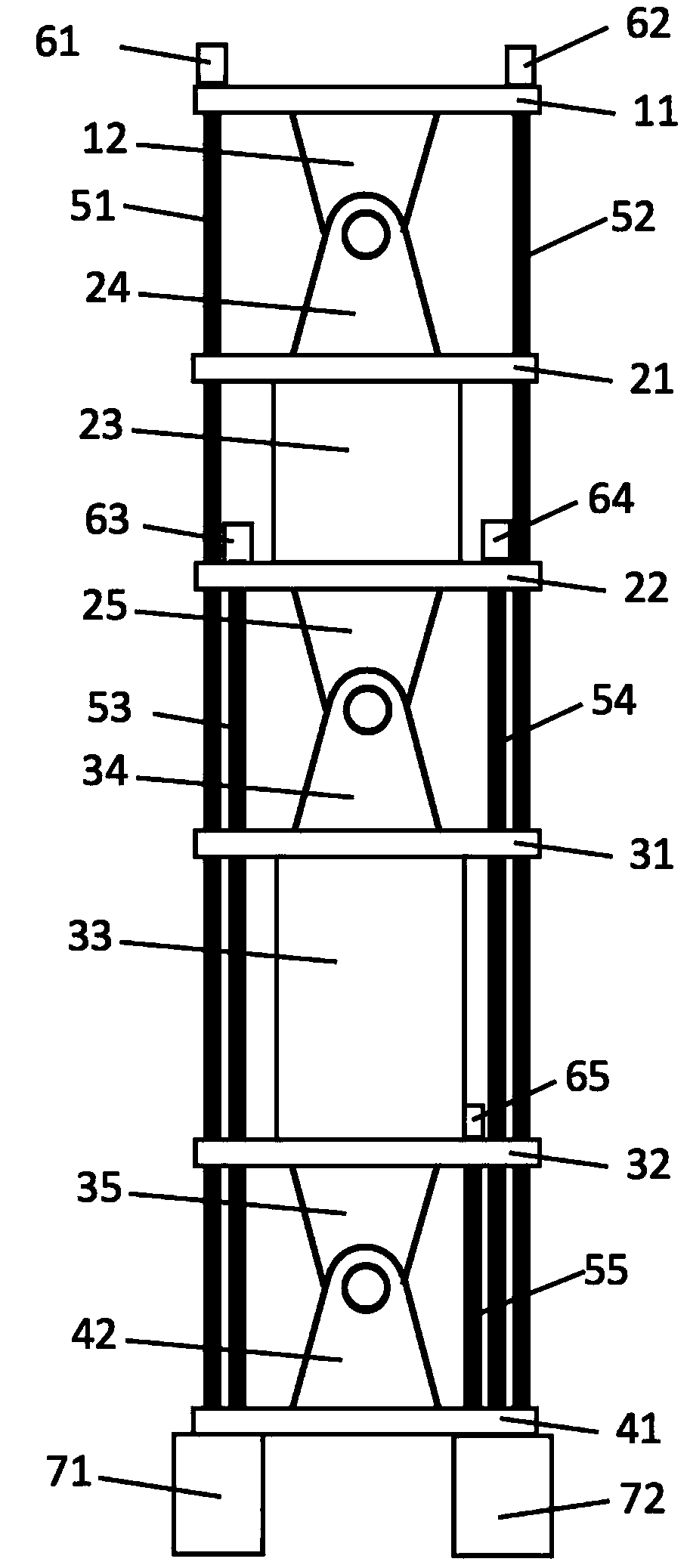

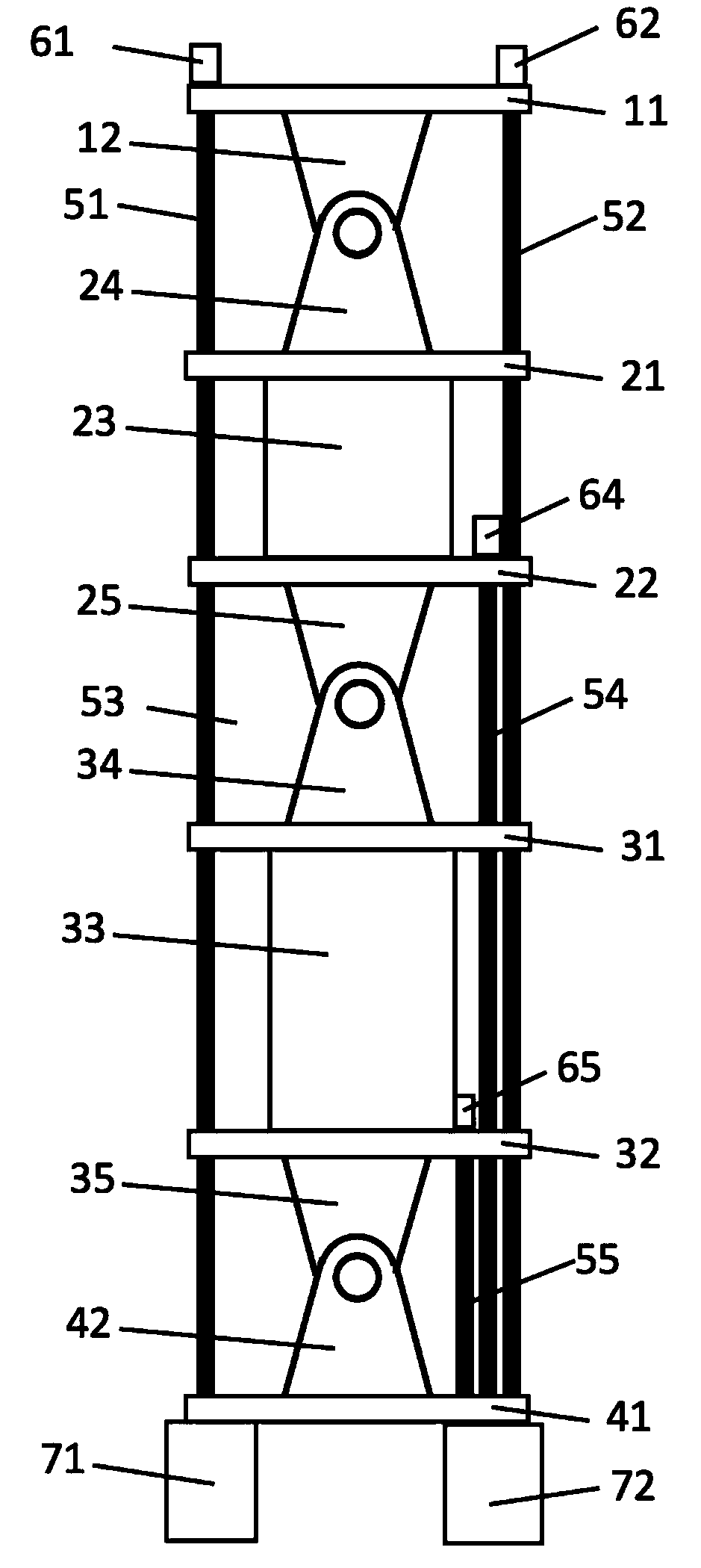

[0028] ginseng figure 1 As shown, an under-actuated rope-driven mechanical arm in this embodiment includes a plurality of rotatable joints, driving ropes connected between the joints, and several ropes for retracting and / or releasing the wires. The joint includes a first joint at the bottom, a second joint at the top, and several third joints between the first joint and the second joint. Directly or indirectly connected, at least one side of the third joint is directly or indirectly connected to the first joint through the second driving rope.

[0029] The joint in this embodiment includes several connecting plates and support frames fixedly installed on the connecting plates, and the joints are installed through the rotating support frame.

[0030] Specifically, this embodiment includes four joints, one first joint, one second joint and two third joints. The first joint includes a first connecting plate 41 and a first support frame 42, the second joint includes a second con...

Embodiment 2

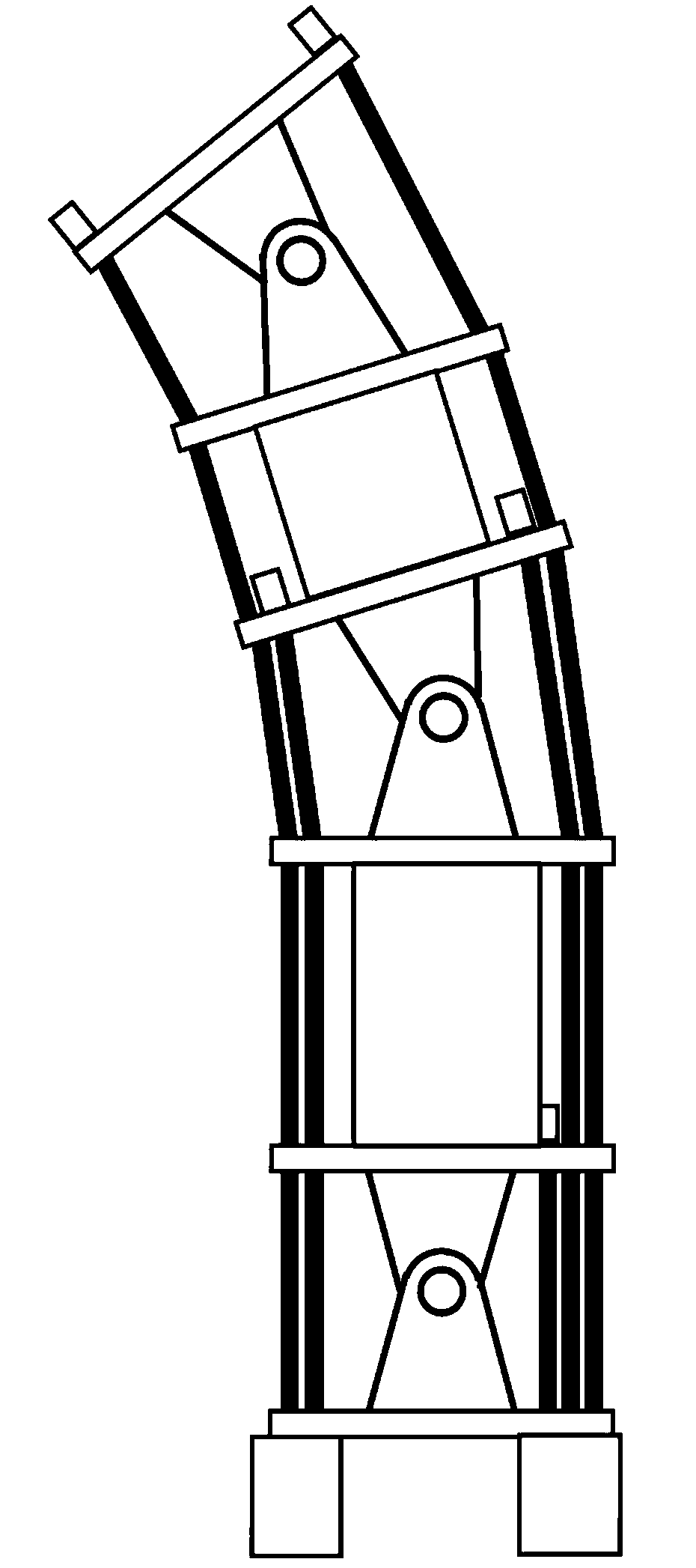

[0046] ginseng image 3 As shown, in the under-actuated rope-driven mechanical arm in this embodiment, the joint structure is exactly the same as in Embodiment 1. The difference from Embodiment 1 is that only four driving ropes are included in this embodiment. The first driving rope 51, 52. The arrangement of the second driving rope 54 and the second driving rope 55 is exactly the same as that in Embodiment 1, and the second driving rope 53 and the corresponding head sealer 63 in Embodiment 1 are not provided in this embodiment.

[0047] to combine Figure 4 As shown, the control principle of the rope-driven mechanical arm in this embodiment is as follows:

[0048] The counterclockwise rotation of the second joint, the upper third joint, and the lower third joint is all realized by pulling the first drive rope 51 through the rope retractor 71. When the rope retractor 71 pulls the first drive rope 51, the rope retracts and retracts. The device 72 releases the first driving ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com