Continuous type stepping motor drive transverse longitudinal sealing roller packing machine and control method thereof

A stepper motor, packaging machine technology, applied in packaging automatic control, packaging, transportation and packaging, etc., can solve the problem of increasing assembly and debugging costs, inconvenience in operation and use, and machining errors in mechanical transmission parts. The bag phenomenon is difficult to overcome and other problems, so as to save assembly and debugging costs, facilitate market users, and improve the level of electrical automation production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

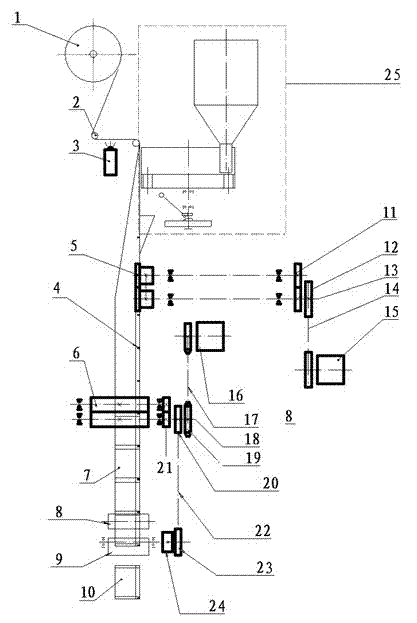

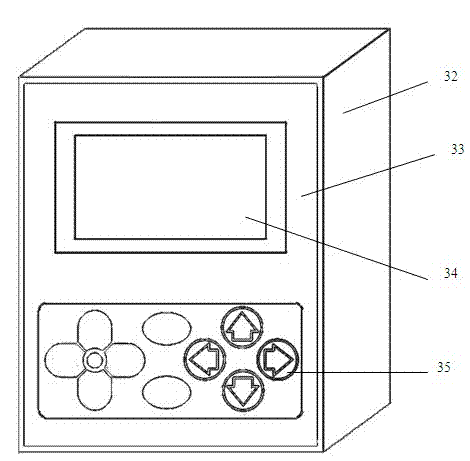

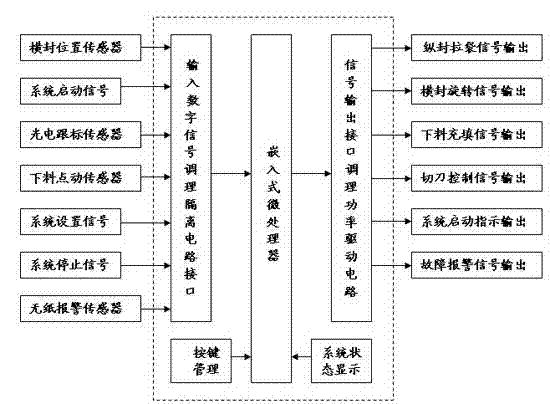

[0048] The specific implementation, structure, features and effects provided by the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

[0049] Such as Figure 1~4 The shown is a continuous stepping motor driven horizontal and vertical sealing roller packaging machine, including a longitudinal sealing traction drive mechanism, a horizontal sealing rotation drive mechanism, a finished bag cutting mechanism, a material filling device and a packaging machine system controller, and a longitudinal sealing traction drive mechanism. The mechanism consists of longitudinal sealing roller 5, longitudinal sealing drive stepper motor 15, composite film coil 1, guide roller 2, longitudinal sealing drive timing belt 14, longitudinal sealing drive timing pulley 12, longitudinal sealing drive direction changing gear 11, longitudinal sealing Composed of transmission shaft 13, the traction of the longitudinal sealing roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com