Gantry type lathe mechanical hand

A manipulator, gantry-type technology, applied in the direction of manipulators, program-controlled manipulators, metal processing, etc., can solve problems such as inability to use, mechanical failure of the Zhuang clamping device, and splashing of processing waste, and achieve the effect of functional improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] To facilitate the understanding of those skilled in the art, the following is attached Figure 1-9 , The technical scheme of the present invention is further explained in detail.

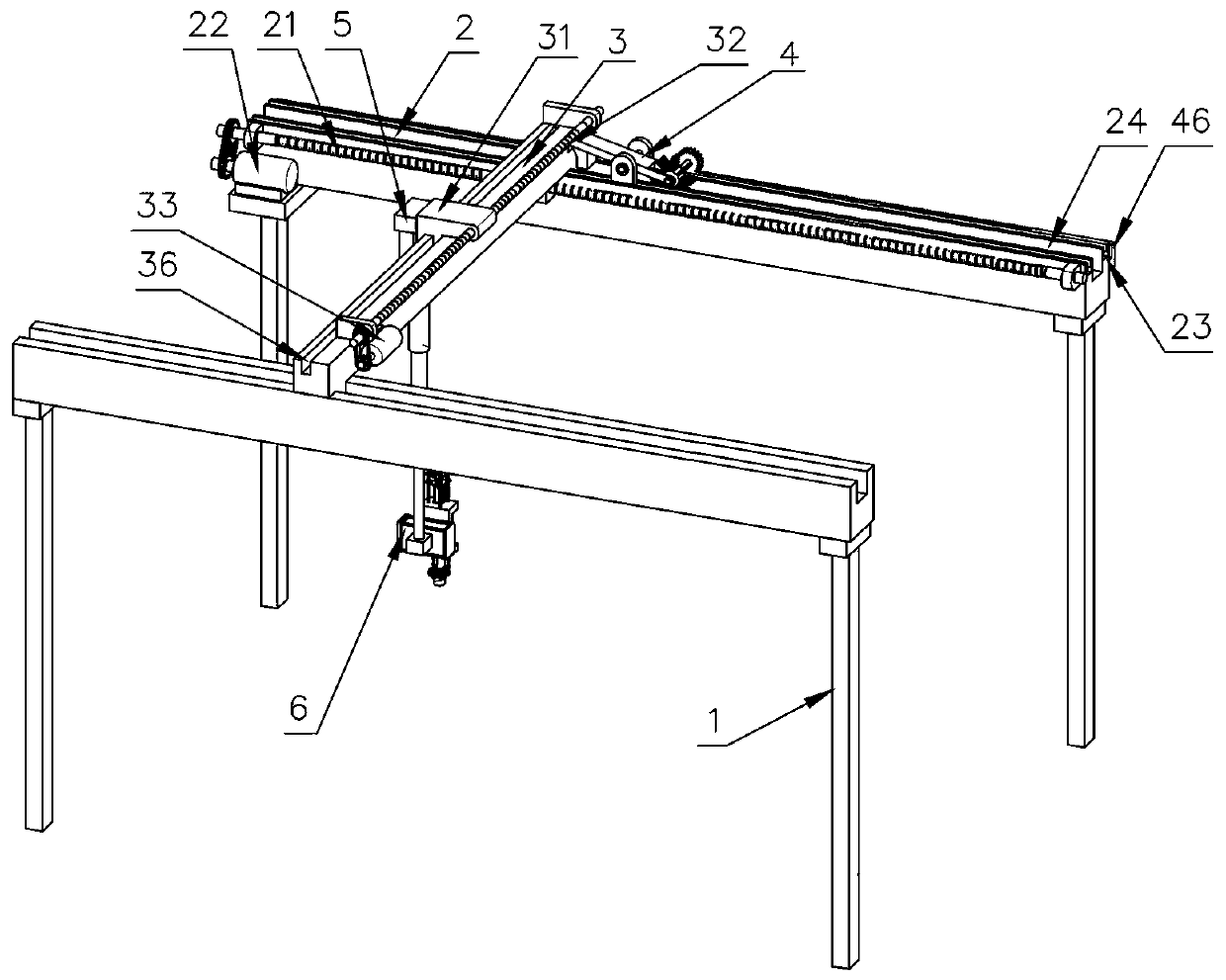

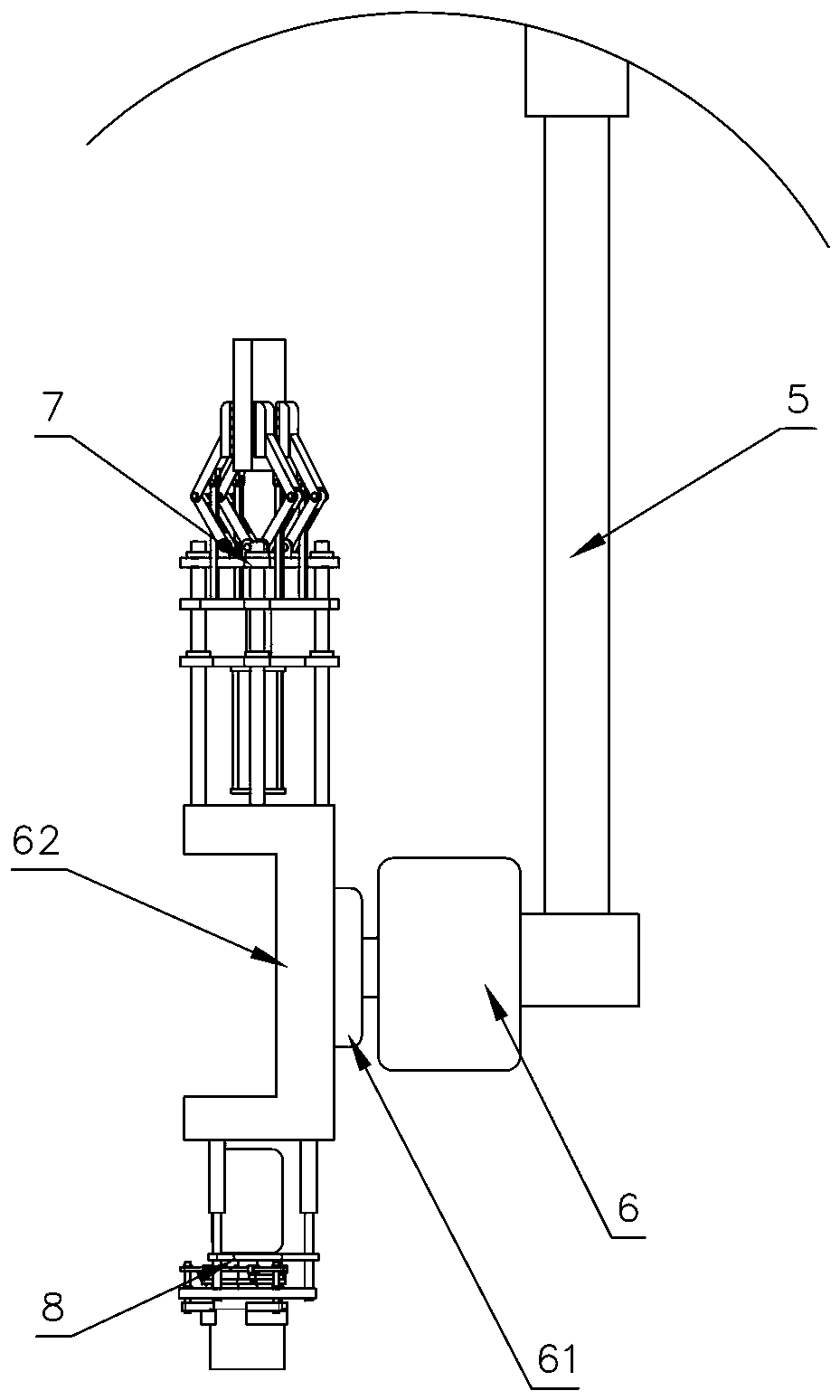

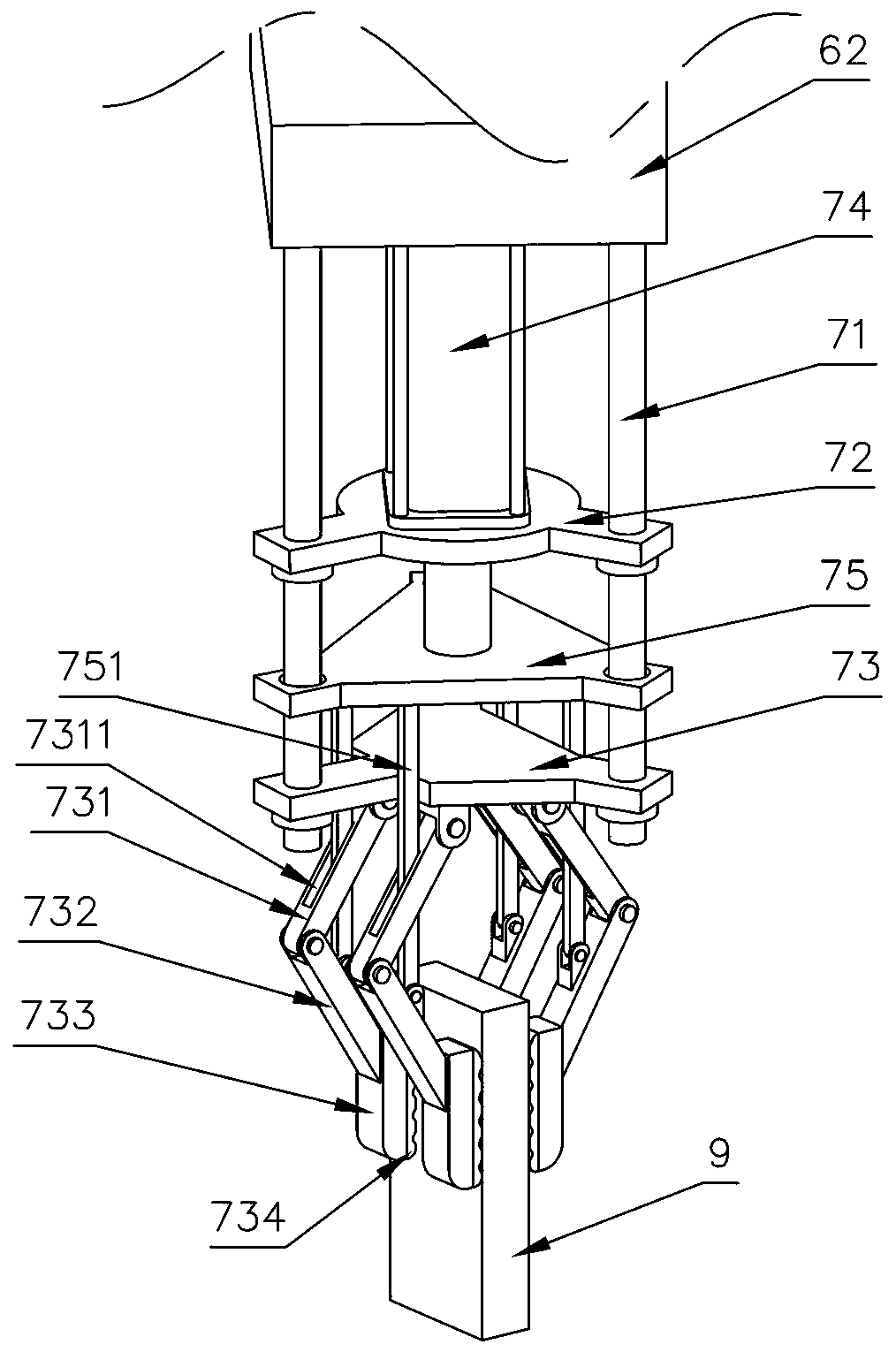

[0031] A gantry type lathe manipulator, comprising a column 1, a beam 2, a longitudinal beam 3, a chip removal device 4, a telescopic electric cylinder 5, a rotary electric cylinder 6, a jaw Ⅰ 7, and a jaw Ⅱ 8. The two ends of the cross beam 2 are fixed on the column 1. At the top end, both ends of the longitudinal beam 3 are movably linked to the beam 2, the chip removal device 4 is located at one end of the longitudinal beam 3 and movably connects the beam 2 and the longitudinal beam 3, and the telescopic electric cylinder 5 is movably connected to the longitudinal beam 3. The rotary electric cylinder 6 is fixedly connected to the telescopic electric cylinder 5, and the jaws I7 and II8 are fixedly connected to the rotary electric cylinder 6 respectively.

[0032] The longitudinal beam 3 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com