Integrated machine for breaking, loading, carrying, spraying and tunneling of rock roadway

A rock roadway and rock breaking technology, which is applied in the field of coal mine excavation equipment, can solve problems such as poor operating safety environment, a lot of time spent, and high labor intensity of employees, so as to reduce the mechanical failure rate, increase the excavation speed, explosion-proof performance and Good safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Describe in detail below in conjunction with accompanying drawing:

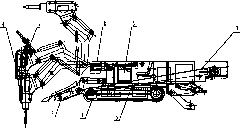

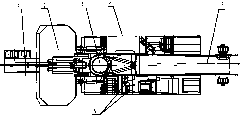

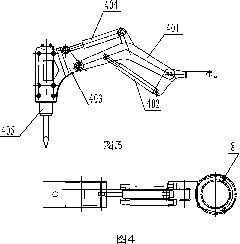

[0039] figure 1 and figure 2 As shown, the rock roadway excavation, breaking, loading and spraying integrated machine of the present invention. The rock roadway excavation, breaking, loading, spraying integrated machine includes a crawler walking part 1 and a belt transporting part 2, a raking rock breaking part 3, a spraying device 4, a hydraulic pressure and an operating system 5, a base 6 and a body platform 7. The part is composed of a belt conveyor, and the pusher and rake shovel are installed in front of the crawler walking part, and the belt conveyor is installed behind the shovel and in the middle of the crawler walking part; the hydraulic pressure and the operating system are installed on the crawler. Part of the upper body platform 7; the base is fixed on the front middle part of the body platform 7, the rock raking part is movably connected to the base 6, and the spraying device is mounte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com