Lifting and transferring machinery for construction of construction site

A construction site and machinery technology, applied in the field of lifting and transferring machinery for construction site construction, can solve the problems of too simple structure, prone to failure, threatening the personal safety of staff, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

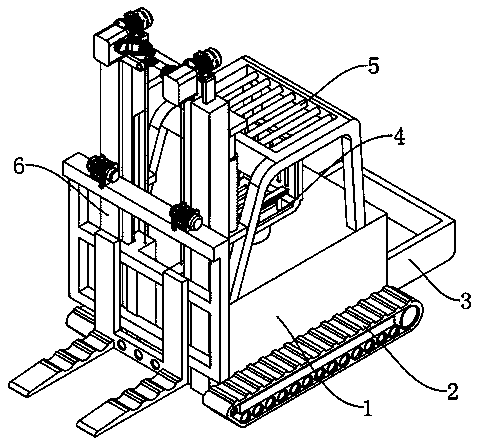

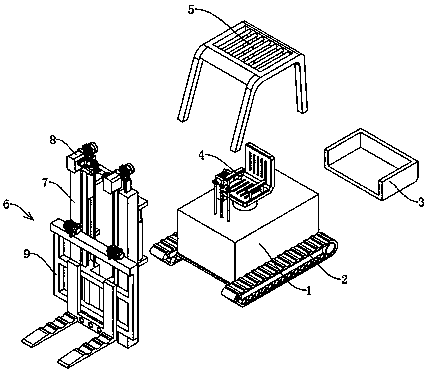

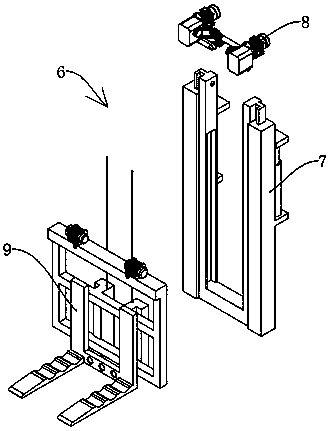

[0027] see Figure 1-4, a lifting transfer machine for construction site construction, comprising a machine main body 1 and a traveling crawler belt 2, the traveling crawler belt 2 is fixedly installed on both sides of the lower end of the machine main body 1, a carrying box 3 is fixedly connected to the tail of the machine main body 1, and the machine main body 1 A driver's cab 4 is arranged above, and a driver's seat and a control device are fixedly installed inside the driver's cab 4, and a protective frame 5 is fixedly connected around the driver's cab 4; a lifting transfer device 6 is connected to the front end of the machine body 1, and the lifting transfer device 6 includes Hydraulic lifting mechanism 7, cable driving mechanism 8 and cable lifting mechanism 9, hydraulic lifting mechanism 7 is connected on the mechanical main body 1, and cable driving mechanism 8 and cable lifting mechanism 9 are connected on the hydraulic lifting mechanism 7.

[0028] The hydraulic lift...

Embodiment 2

[0031] see Figure 5 , based on Embodiment 1, the difference is that;

[0032] The cable driving mechanism 8 includes a servo lifting motor 801, the servo lifting motor 801 is fixedly connected to the top of the connecting rod 703, the tail of the servo lifting motor 801 is fixedly connected with an electromagnetic brake 817, and the end of the servo lifting motor 801 away from the electromagnetic brake 817 is provided with a Mounting case 802, mounting case 802 is also fixedly connected with connecting rod 703, the inside of mounting case 802 is provided with pinion 803, pinion 803 is fixedly connected on the output shaft of servo lifting motor 801, and pinion 803 is meshed with big gear 804 .

[0033] The large gear 804 is fixedly connected to the first worm 805, and the first worm 805 rotates inside the installation shell 802. The first worm 805 is meshed with the first worm wheel 806, and the first worm wheel 806 is fixedly connected to the first connecting shaft 807. A ...

Embodiment 3

[0037] refer to Figure 6 ; Based on Embodiment 1 or 2, the difference is that;

[0038] The cable lifting mechanism 9 includes a fixed rod 901 and a lifting cable 902. The fixed rod 901 is slidably connected to the mounting groove 707. The bottom end of the lifting cable 902 is fixedly connected to the top of the fixing rod 901. The upper end of the lifting cable 902 is wound and connected to On the winding roller 816, the fixed rod 901 is also fixedly connected with a connecting frame 903, the connecting frame 903 is fixedly connected with a lifting transfer frame 904, and the bottom of the lifting transfer frame 904 is fixedly connected with an auxiliary fixing frame 905, and the auxiliary fixing frame 905 is set There are fixing holes, and an electric winch 906 is fixedly installed on the top of the connecting frame 903 , and the electric winch 906 is matched with the auxiliary fixing frame 905 .

[0039] The cable lifting mechanism 9 of the present invention is matched w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com