Small forced vibrating asynchronous-clamping hydraulic tamper

A technology of forced vibration and tamping machine, which is applied in the direction of roads, tracks, ballast layers, etc., and can solve the problems of poor ability of eccentric vibration to disturb the ballast bed, inability to guarantee the quality of tamping operations, and failure to achieve the effect of asynchronous clamping operations, etc. , to achieve the effect of light weight, simple structure and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

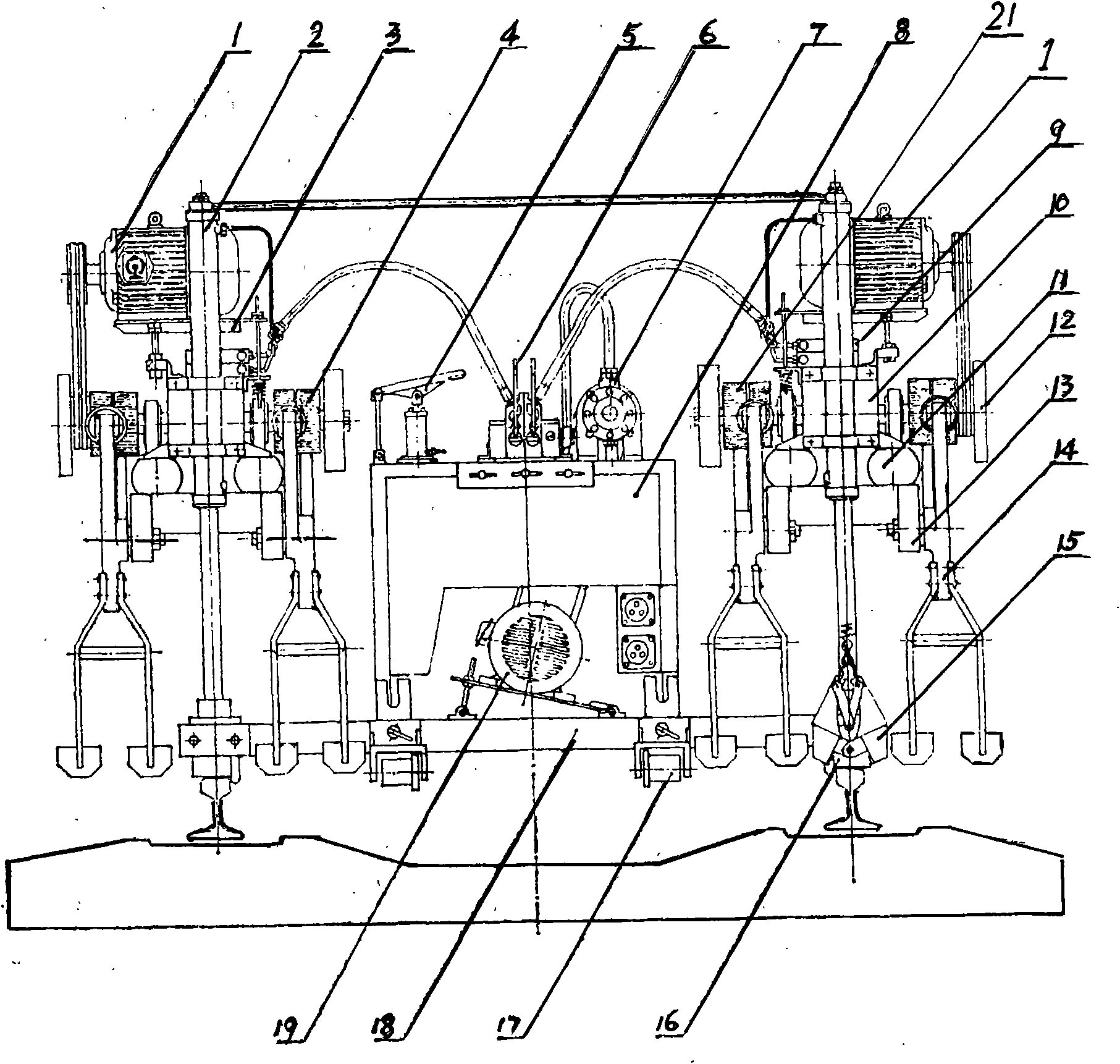

Embodiment 1

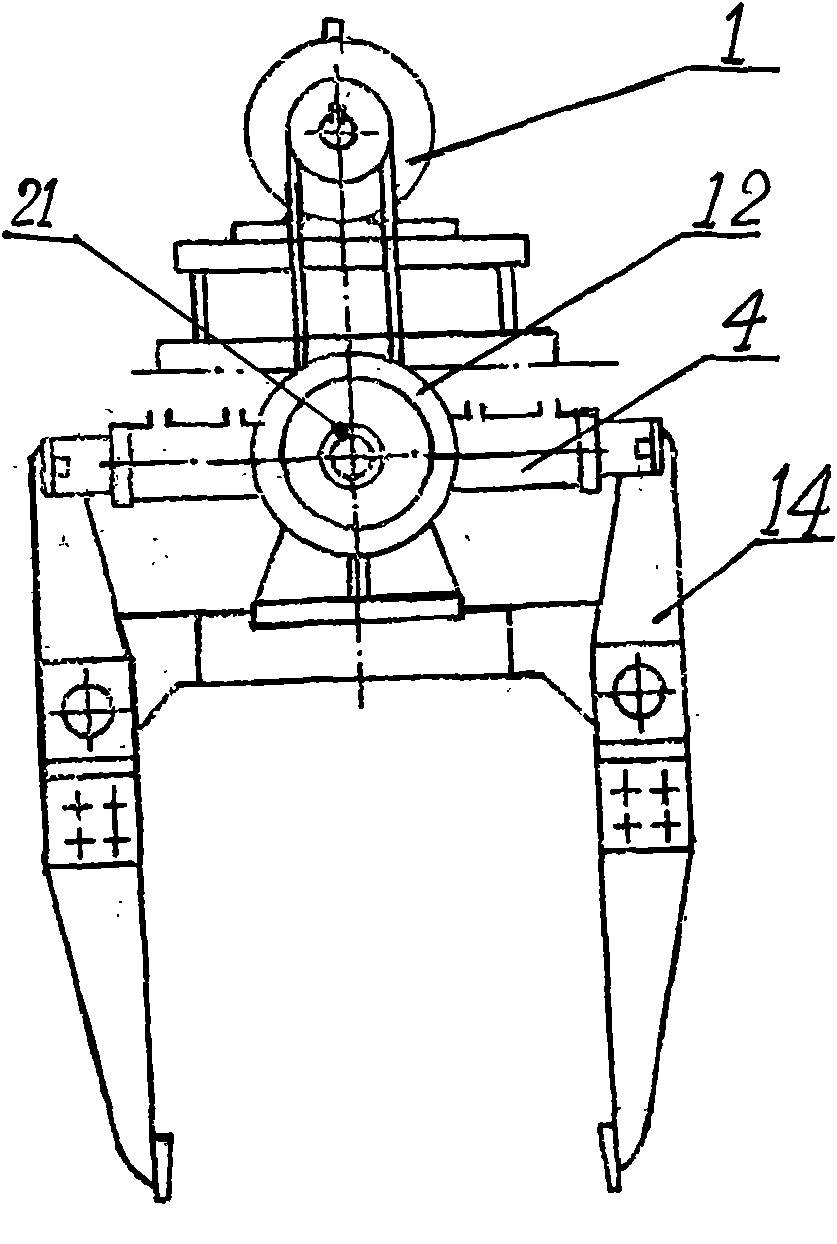

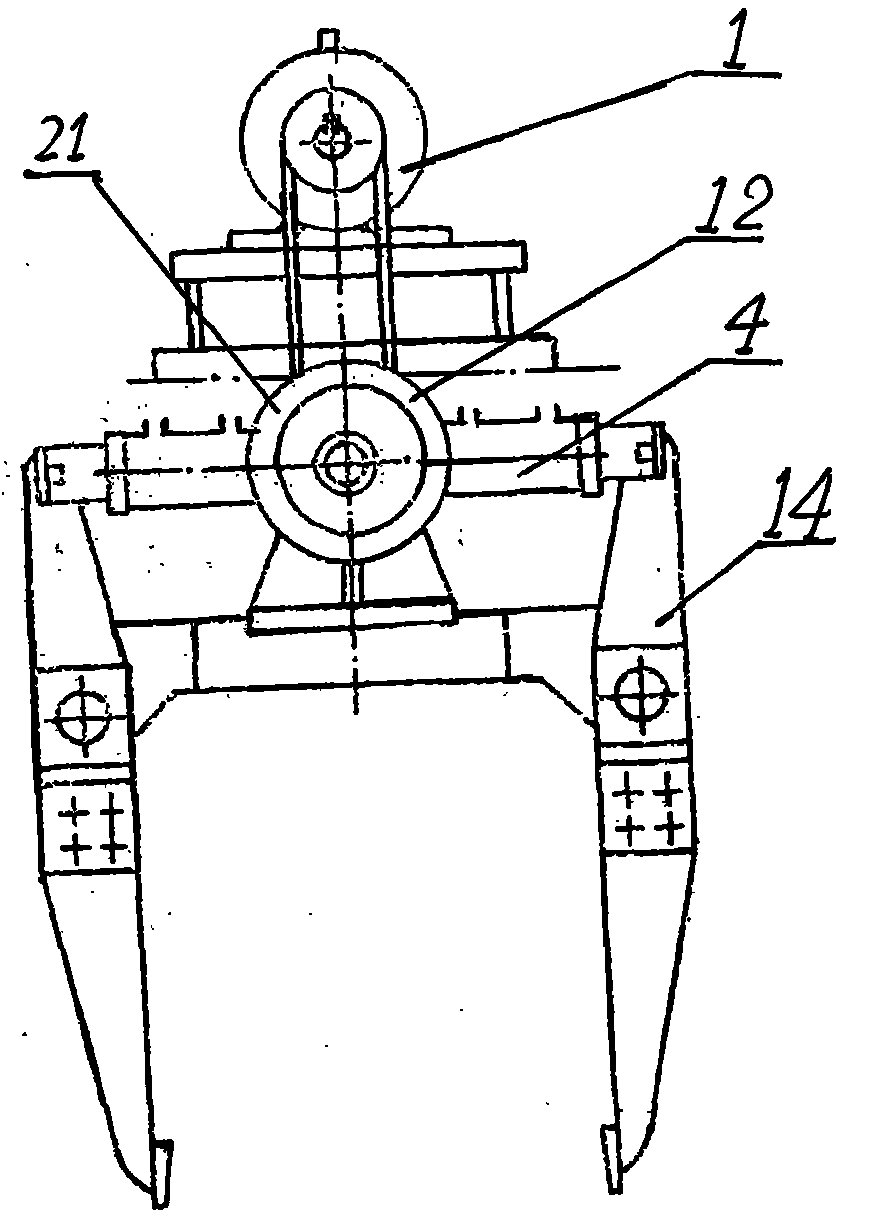

[0015] The number of ramming picks in this embodiment is 16 picks / set, which is composed of a lifting part, a running part, and an exciting and clamping part. It consists of a motor 1, a lifting cylinder 2, a frame 3, a back pressure clamping cylinder 4, and a hand pump 5. Combination reversing valve 6, vane pump 7, fuel tank 8, back pressure valve 9, upper frame 10, rubber shock absorber 11, flywheel 12, lower frame 13, pick plate 14, rail clamp 15, traveling wheel 16 , The lower wheel 17, the underframe 18 and the oil pump motor 19. The vibration excitation clamping part is composed of a flywheel 12, a spline shaft 20, an eccentric bearing 21, a clamping oil cylinder 4 and a pick plate 14. One end of the motor 1 belt is sleeved on the output shaft of the vibrating motor 1, and the other end is sleeved on a spline shaft 20. The outer end of the spline shaft 20 is sleeved with a flywheel 12, and four eccentric bearings 21 are sequentially installed on the spline shaft 20, each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com