Flour milling device for flour milling

A flour and flour milling technology, which is applied in magnetic separation, solid separation, grain processing, etc., can solve the problems affecting the quality of flour and the bran of grains that cannot be effectively removed, so as to avoid personal injury and improve the quality of flour

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

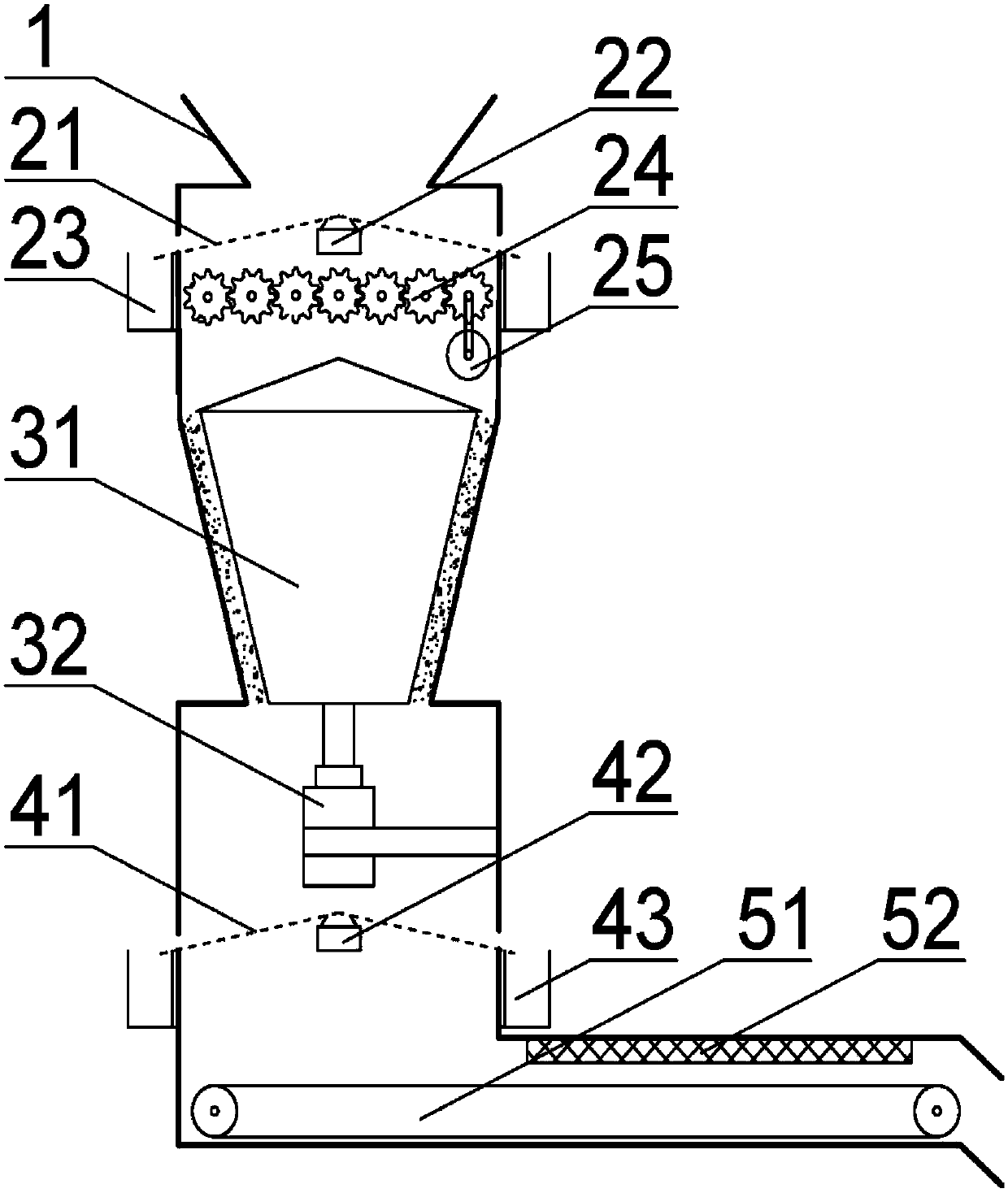

[0013] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of a milling device for flour processing proposed by the present invention.

[0014] refer to figure 1 , a milling device for flour processing proposed by the present invention, comprising a feed hopper 1, a primary impurity removal chamber and an abrasive chamber connected sequentially from top to bottom; the primary impurity removal chamber is provided with a first vibrating sieve 21 and seven crushing Gear 24, the first vibrating screen 21 removes impurities from the materials to be ground, such as bran, straw, etc., and the grinding gear 24 is used for pre-rolling the materials to be ground. The first vibrating screen 21 is located at the outlet of the feeding hopper 1 and seven Between the crushing gears 24, the first vibrating screen 21 is connected to the first vibrator 22, and the first vibrator 22 drives the first vibrating screen 21 to vibrate. Seven crushing gears 24 are rotatably inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com