Flame-retardant heat conductive insulation silicone rubber product for power equipment and preparing method of flame-retardant heat conductive insulation silicone rubber product

A heat-conducting insulation and power equipment technology, applied in the field of flame-retardant heat-conducting insulating silicone rubber products and its preparation, can solve the problems of burning insulating materials, fire, short-circuit fault economy, etc., and achieve the effect of preventing materials from gelling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

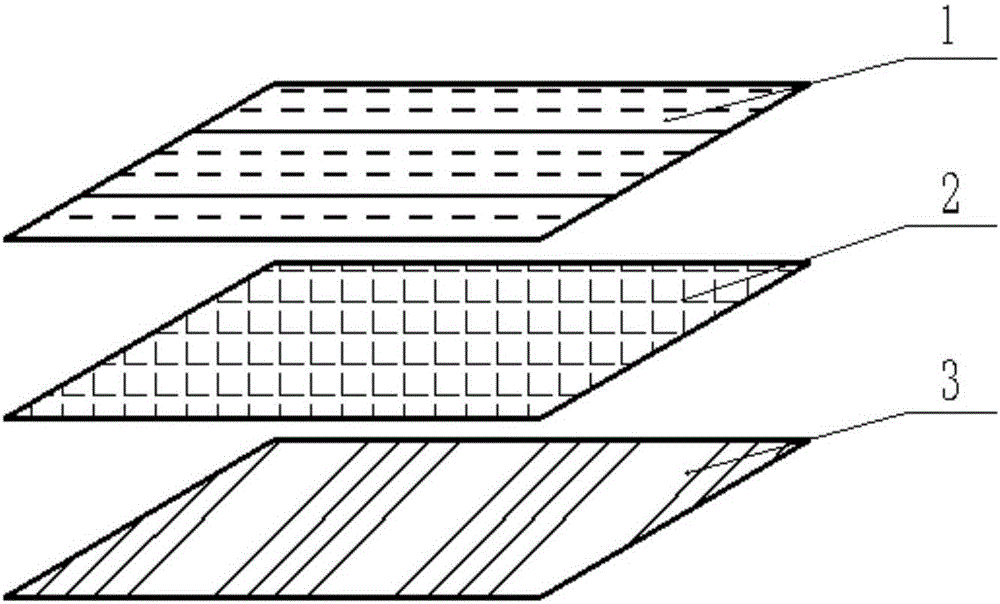

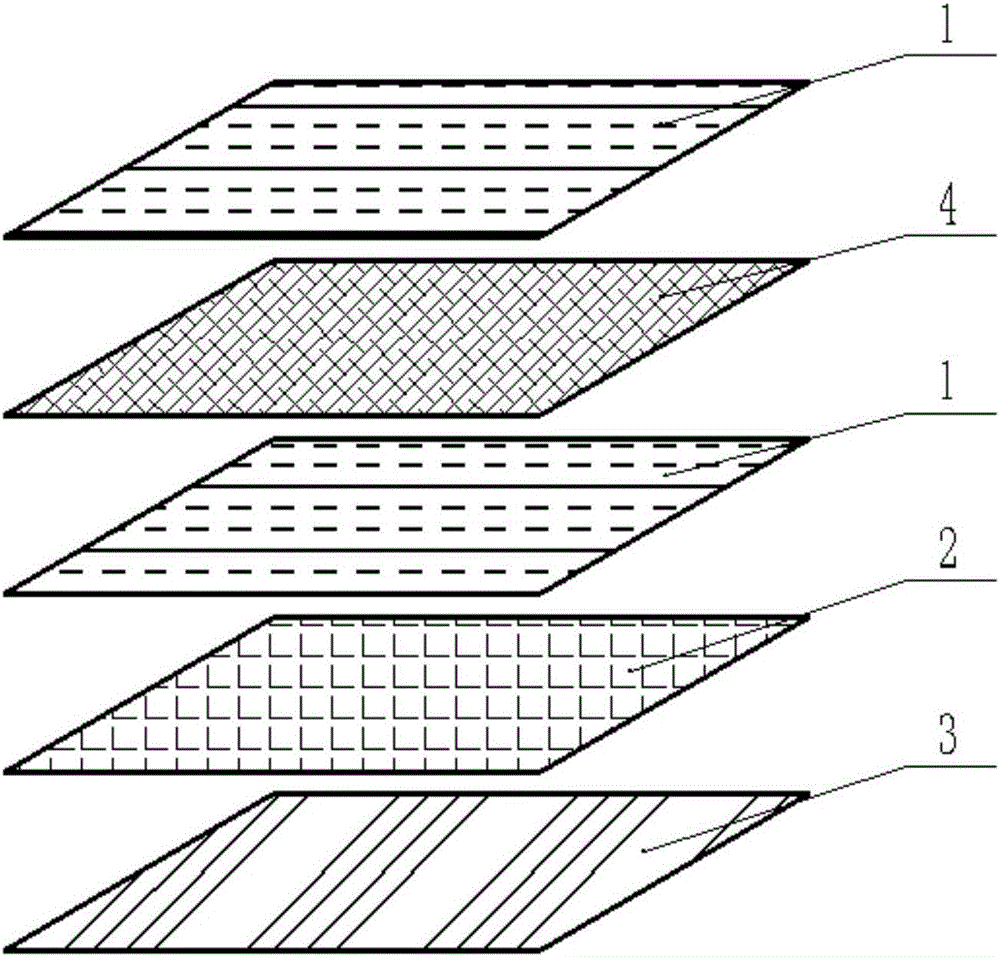

Image

Examples

preparation example Construction

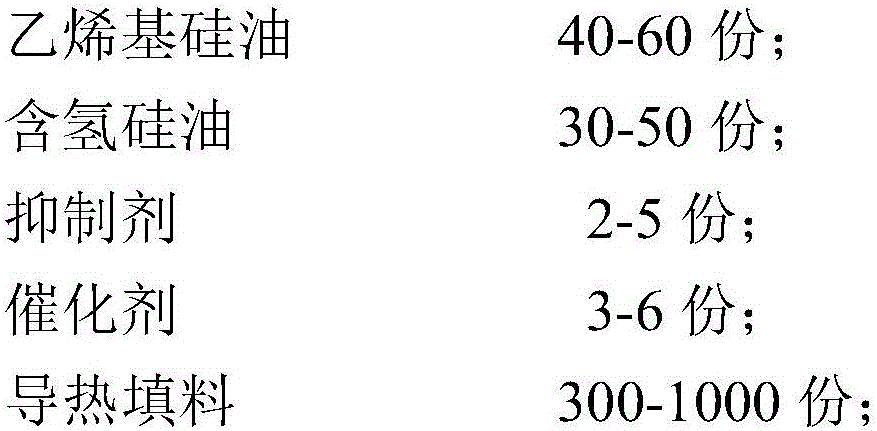

[0051] A method for preparing a flame-retardant and heat-conducting silicone rubber insulating silicone rubber product for power equipment, comprising the steps of:

[0052] b. Add the formulated amount of vinyl silicone oil and hydrogen-containing silicone oil into the stirring tank, stir evenly at a speed of 40-60rpm, then add the prepared alumina filler, adjust the speed to 50-120rpm; heat to 80-120°C Finally, turn on the vacuum to remove air bubbles and small molecular substances, and maintain it for 1.5-2 hours at a speed of 50-120rpm, so that the materials in the stirring tank are evenly mixed;

[0053] c. After the material obtained in step b is cooled to room temperature, first add the formulated amount of inhibitor, stir evenly at a speed of 40-80rpm, then add the formulated amount of catalyst, mix evenly at a speed of 40-80rpm, and then vacuumize Until the air bubbles in the material are completely extracted, the rubber material is obtained;

[0054] d. Place the ru...

Embodiment 1

[0060] a. Pre-preparation of various raw materials: First, mix 50 μm large-sized alumina particles and 6 μm small-sized alumina particles in a mixer according to the mass ratio of 4:6 to obtain alumina fillers, and pack them for use;

[0061] Stir and mix 99 kg of vinyl silicone oil with a viscosity of 500 mPa·s and 1 kg of acetylene cyclohexanol at a speed of 40 rpm to obtain a vinyl silicone oil inhibitor containing 0.1% of acetylene cyclohexanol, which is ready for use;

[0062] Mix 2.3kg of methyl silicone oil with a viscosity of 100mPa·s and 1kg of a platinum catalyst with a content of 0.005wt% at a speed of 45rpm to obtain a catalyst containing 0.0015wt% platinum per kilogram, which is ready for use;

[0063] b. According to the formula requirements, add 55 parts of vinyl silicone oil with a viscosity of 3000mPa·s and a vinyl content of 1.2, and 45 parts of hydrogen-containing silicone oil with a viscosity of 100mPa·s and a hydrogen content of 0.1% into the stirring tank ...

Embodiment 2

[0070] Embodiment 2 is different from Embodiment 1 in that, taking the production of a 2mm flat silicone rubber sheet as an example, in step d, the distance between the pressure roller in the calender and the transmission belt is adjusted to 2 ± 0.2mm and the transmission belt is adjusted to The transmission speed is 20m / min, and then pour the rubber compound obtained in step c onto the PE film pre-laid on the conveyor belt, and vulcanize and mold it at a temperature of 120°C and a vulcanization time of 30s to obtain a sheet-shaped barrier. Semi-finished products of heat-conducting insulating silicone rubber products.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com