Heating furnace flue gas and steam waste heat recycling and power generating system and power generating method

A flue gas waste heat and waste heat recovery technology, applied in the field of metallurgy, to achieve good social and economic benefits, increase power generation, and reduce product costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

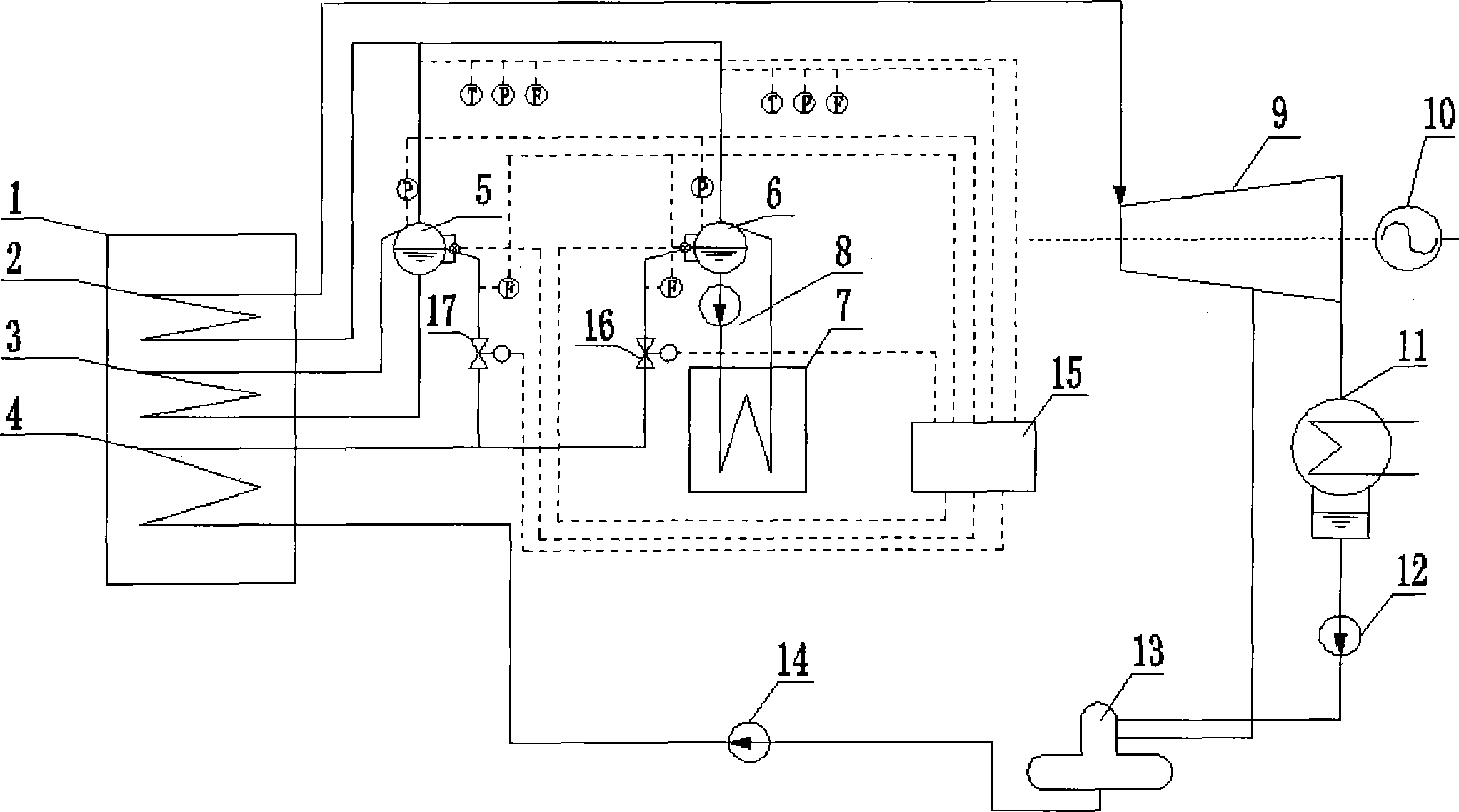

[0054] The system of the present invention mainly includes flue gas waste heat boiler 1, superheater 2, evaporator 3, economizer 4, flue gas waste heat boiler steam drum 5, vaporization cooling steam drum 6, heating furnace water beam vaporization cooling circuit 7, vaporization cooling Forced circulation pump 8, steam turbine 9, generator 10, condenser 11, condensate pump 12, thermal deaerator 13, boiler feed water pump 14, combined control system 15, vaporization cooling drum feed water regulating valve 16, flue gas waste heat boiler Drum feedwater regulating valve 17, etc.

[0055] This system introduces the 400-500°C flue gas at the tail of the main exhaust flue of the heating furnace into the flue gas waste heat boiler 1, and the flue g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com