Special welding fixture for copper aluminum tube and welding method and copper aluminum welded tube utilizing the same

A special fixture and welding fixture technology, applied in welding equipment, manufacturing tools, resistance welding equipment, etc., can solve the problems of low production efficiency and high production cost, and achieve the effect of improving service life, increasing strength, and reducing demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

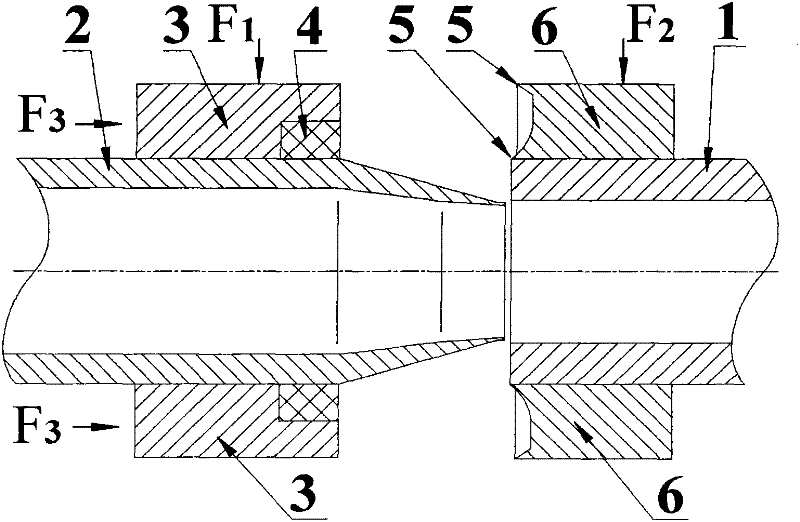

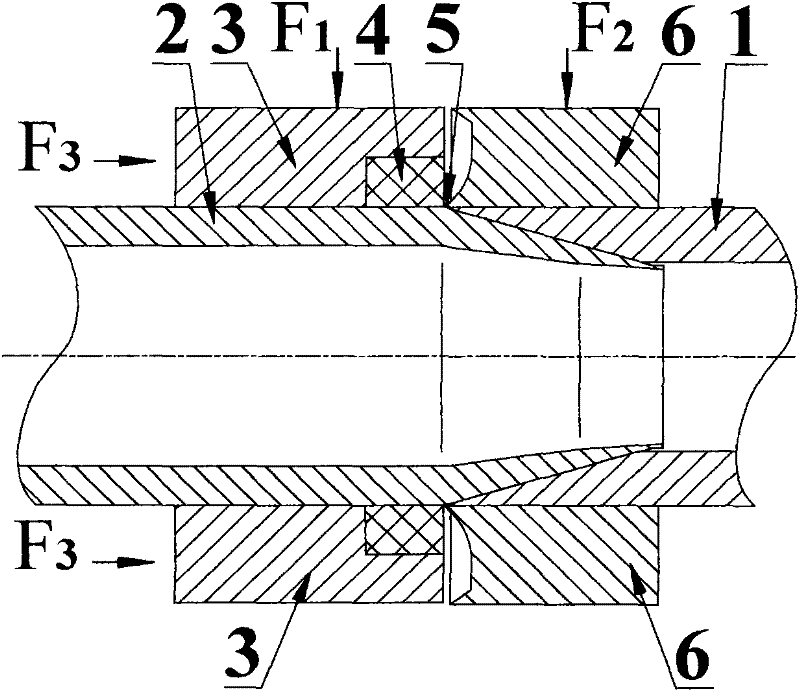

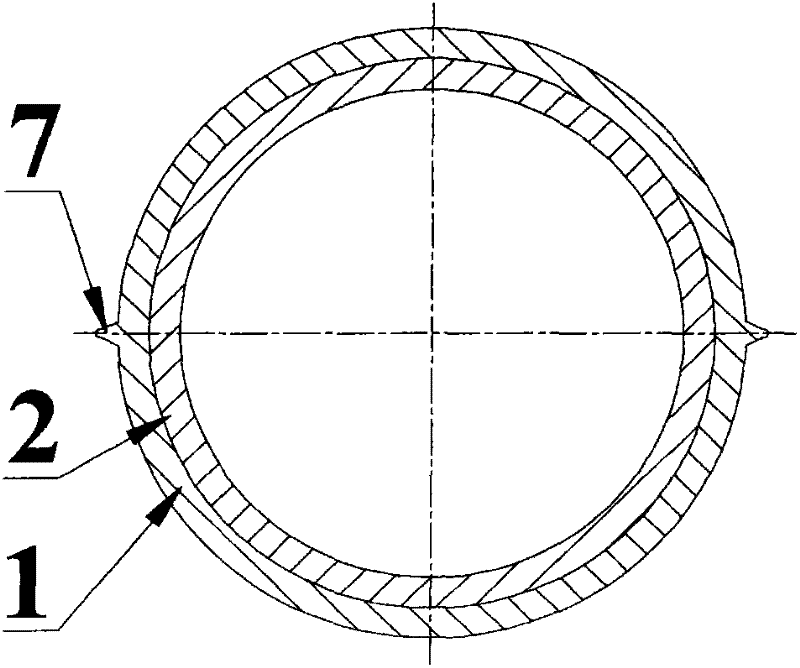

[0016] Such as Figure 1 to Figure 4 As shown, the specific embodiment of the invention is as follows: a special fixture for copper-aluminum pipe welding, including a grinding and cutting clamping mold 6 and a backing plate clamping mold 3 that can be used for welding positive and negative electrodes at the same time, and the grinding and cutting clamping mold 6 points It is an upper mold and a lower mold, the upper mold and the lower mold are symmetrical structures, the upper and lower molds respectively include the clamping body of the rear section and the grinding and cutting tool 5 at the front end, and the backing plate clamping mold 3 is also divided into It is an upper mold and a lower mold, and a rigid pad 4 is provided at the front end of the contact part between the backing plate clamping mold 3 and the pipe.

[0017] The grinding and cutting tool 5 is a truncated cone structure, and the front end of the tool or the front end of the rigid spacer 4 is respectively ali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com