Production method of antibacterial coating, antibacterial coating and ventilated antibacterial film containing antibacterial coating

An antibacterial paint, production method technology, applied in the direction of biocide-containing paint, antifouling/underwater paint, chemical instruments and methods, etc. To achieve the effect of simple production process, strong adhesion and little environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

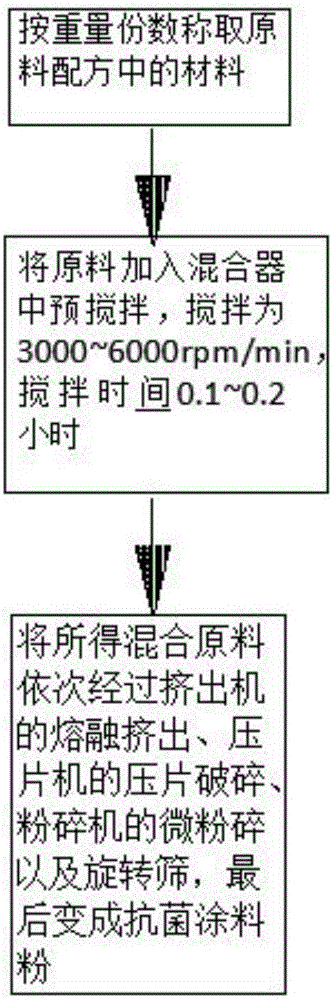

[0031] The invention discloses a method for producing an antibacterial coating, such as figure 1 Shown: including the following steps:

[0032] S1: Weigh the materials in the raw material formula by parts by weight.

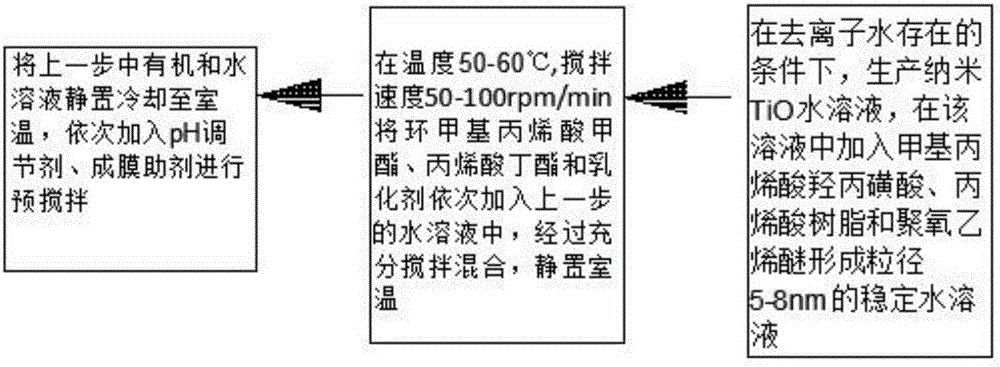

[0033] S2: Add cyclomethyl methacrylate, butyl acrylate, nano-TiO, methacrylic acid hydroxypropanesulfonic acid, acrylic resin, polyoxyethylene ether, emulsifier, deionized water, pH regulator, and film-forming aids to mix Pre-stirring in the container, the stirring is 3000-6000rpm / min, the preferred stirring speed is 4500rpm / min; the stirring time is 0.1-0.2 hours, the preferred stirring time is 0.15 hours; under the conditions of the optimum rotational speed and optimum stirr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com