Method of removing film from edge of coated glass

A coating glass and edge technology, applied in the direction of coating, etc., can solve problems such as complicated operation, rising cost, affecting product quality, etc., and achieve the effect of reliable quality, beautiful edge line, simple and feasible operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

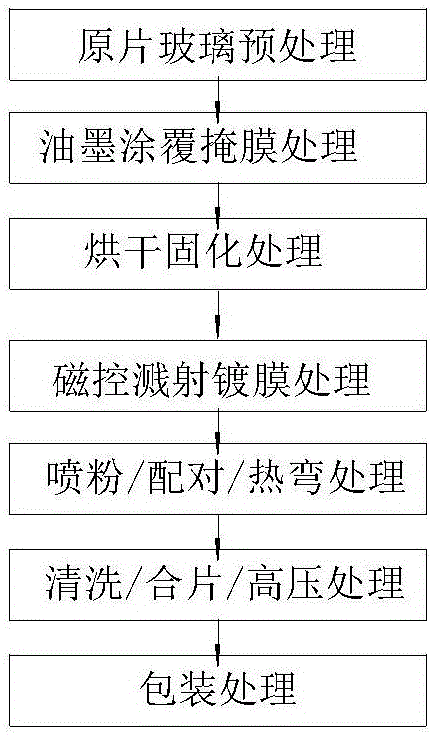

[0045] A method for removing film from the edge of coated glass, comprising the steps of:

[0046]1) Pretreatment of the original glass: the original glass is obtained through pretreatment processes such as cutting, edging, cleaning, drying, and loading;

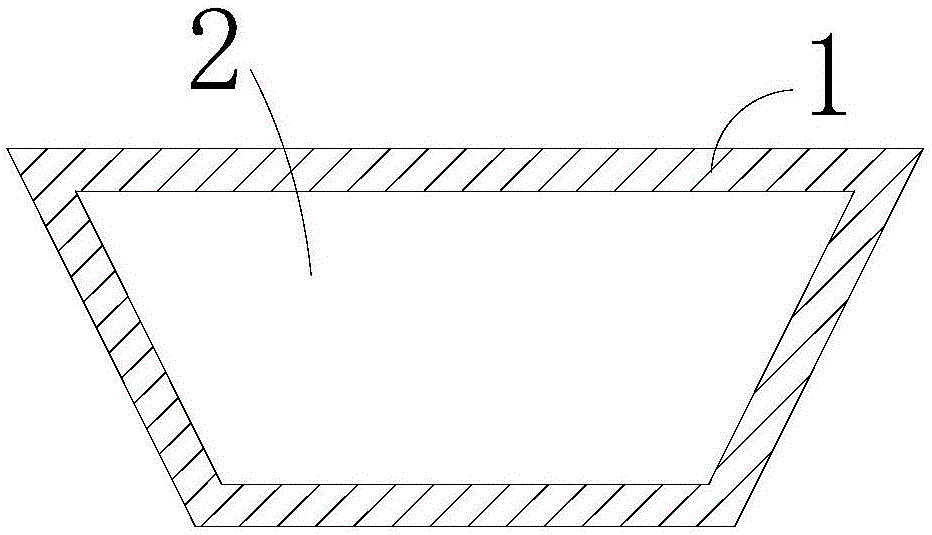

[0047] 2) Masking treatment: Apply low-temperature pyrolysis ink to the area of the original glass surface that does not need to be coated by screen printing process (such as figure 2 2 regions shown);

[0048] 3) Drying and curing treatment: drying the low-temperature decomposition ink on the original glass at a temperature of 95°C to make it solidify;

[0049] 4) Cleaning and coating treatment: On the surface of the original glass coated with low-temperature pyrolysis ink, use the magnetron sputtering coating method to coat the required film layer (the coated film layer is located at figure 2 Middle 1 area);

[0050] 5) Subsequent processing process: the original glass is made into a finished product through powder ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com