Optical fiber Bragg grating temperature sensor for measuring temperature of dry type air-core reactor and application method of optical fiber Bragg grating temperature sensor

A technology of temperature sensors and reactors, applied in thermometers, measuring devices, measuring heat, etc., to achieve the effects of strong corrosion resistance, guaranteed protection measures, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

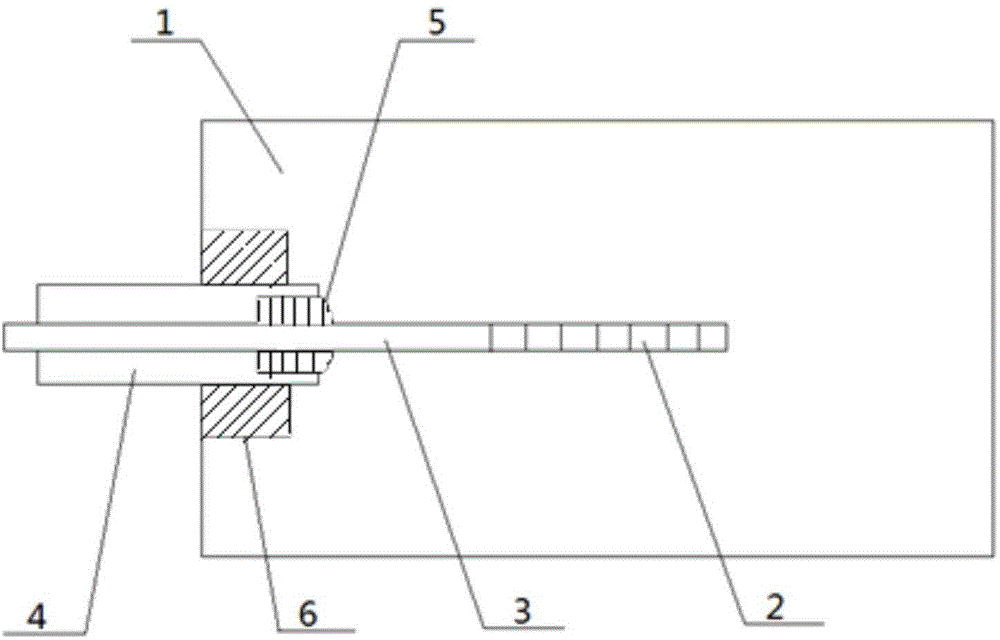

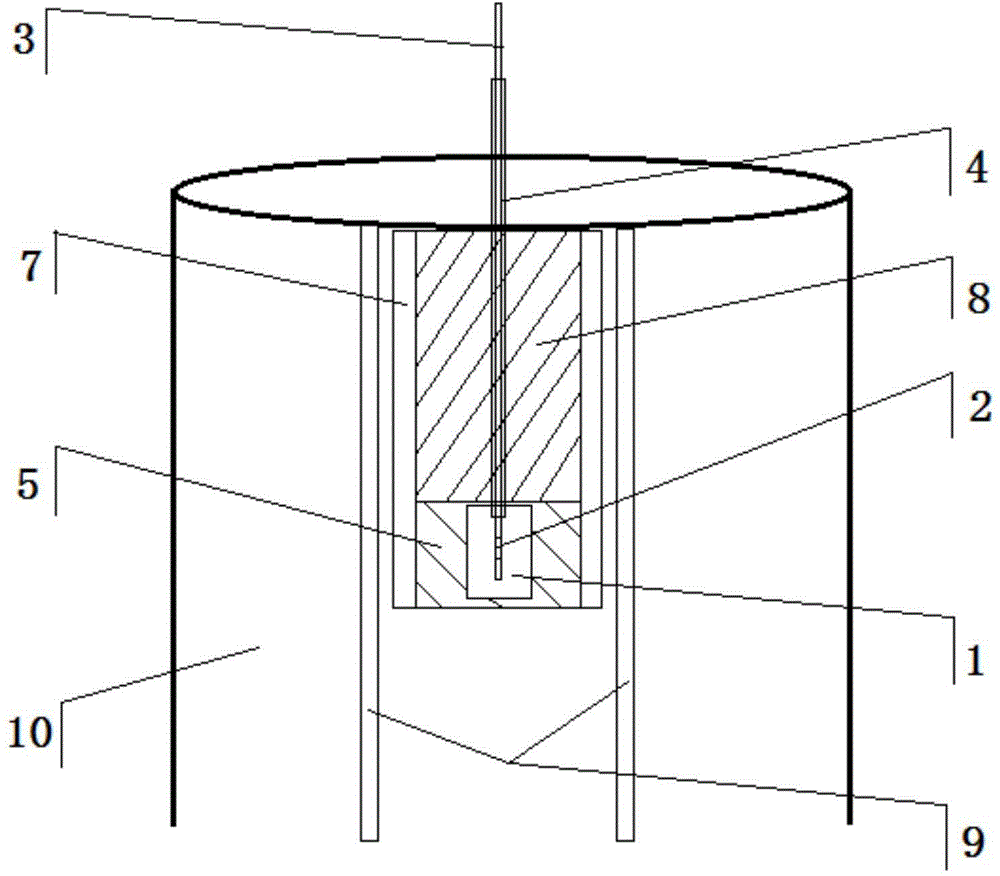

[0043] Embodiment 1: as Figure 1-2As shown, an optical fiber Bragg grating temperature sensor for measuring the temperature of a dry-type air-core reactor includes a polytetrafluoroethylene plate 1, an optical fiber Bragg grating 2, an optical fiber 3, a polytetrafluoroethylene sleeve 4, epoxy resin glue 5, Polytetrafluoroethylene material 6; wherein the optical fiber Bragg grating 2 tail is connected with an optical fiber 3, and the drawn optical fiber 3 passes through the polytetrafluoroethylene sleeve 4, and is adhered and fixed with epoxy resin glue 5 to protect the optical fiber 3 There is a rectangular notch in the middle of the left end of the polytetrafluoroethylene plate 1, and a transverse circular hole is drilled in the notch, which is used for planting the optical fiber Bragg grating 2, and the optical fiber Bragg grating 2 has a cantilever beam structure in the circular hole; The vinyl fluoride material 6 is filled in the rectangular gap, and is integrally packag...

Embodiment 2

[0052] Embodiment 2: as Figure 1-2 As shown, an optical fiber Bragg grating temperature sensor for measuring the temperature of a dry-type air-core reactor includes a polytetrafluoroethylene plate 1, an optical fiber Bragg grating 2, an optical fiber 3, a polytetrafluoroethylene sleeve 4, epoxy resin glue 5, Polytetrafluoroethylene material 6; wherein the optical fiber Bragg grating 2 tail is connected with an optical fiber 3, and the drawn optical fiber 3 passes through the polytetrafluoroethylene sleeve 4, and is adhered and fixed with epoxy resin glue 5 to protect the optical fiber 3 There is a rectangular notch in the middle of the left end of the polytetrafluoroethylene plate 1, and a transverse circular hole is drilled in the notch, which is used for planting the optical fiber Bragg grating 2, and the optical fiber Bragg grating 2 has a cantilever beam structure in the circular hole; The vinyl fluoride material 6 is filled in the rectangular gap, and is integrally packa...

Embodiment 3

[0065] Embodiment 3: as Figure 1-2 As shown, an optical fiber Bragg grating temperature sensor for measuring the temperature of a dry-type air-core reactor includes a polytetrafluoroethylene plate 1, an optical fiber Bragg grating 2, an optical fiber 3, a polytetrafluoroethylene sleeve 4, epoxy resin glue 5, Polytetrafluoroethylene material 6; wherein the optical fiber Bragg grating 2 tail is connected with an optical fiber 3, and the drawn optical fiber 3 passes through the polytetrafluoroethylene sleeve 4, and is adhered and fixed with epoxy resin glue 5 to protect the optical fiber 3 There is a rectangular notch in the middle of the left end of the polytetrafluoroethylene plate 1, and a transverse circular hole is drilled in the notch, which is used for planting the optical fiber Bragg grating 2, and the optical fiber Bragg grating 2 has a cantilever beam structure in the circular hole; The vinyl fluoride material 6 is filled in the rectangular gap, and is integrally packa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com