Prestressed concrete pipe pile anticorrosion joint

A concrete pipe pile, prestressing technology, applied in sheet pile wall, construction, infrastructure engineering and other directions, can solve the problems of poor anti-corrosion ability, narrow welding seam, hidden dangers of engineering safety, etc., to ensure quality and safety, prolong use Longevity and the effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

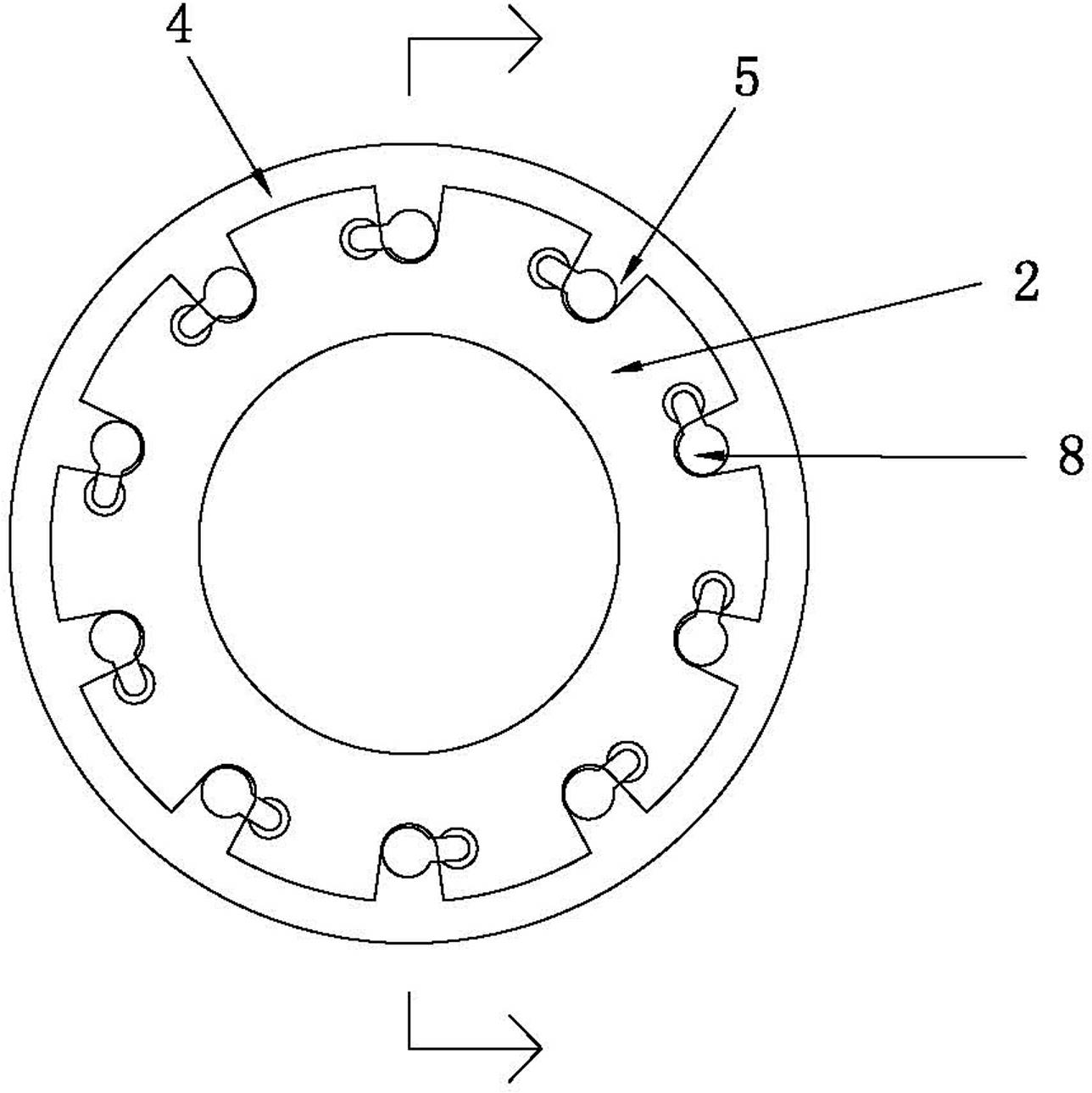

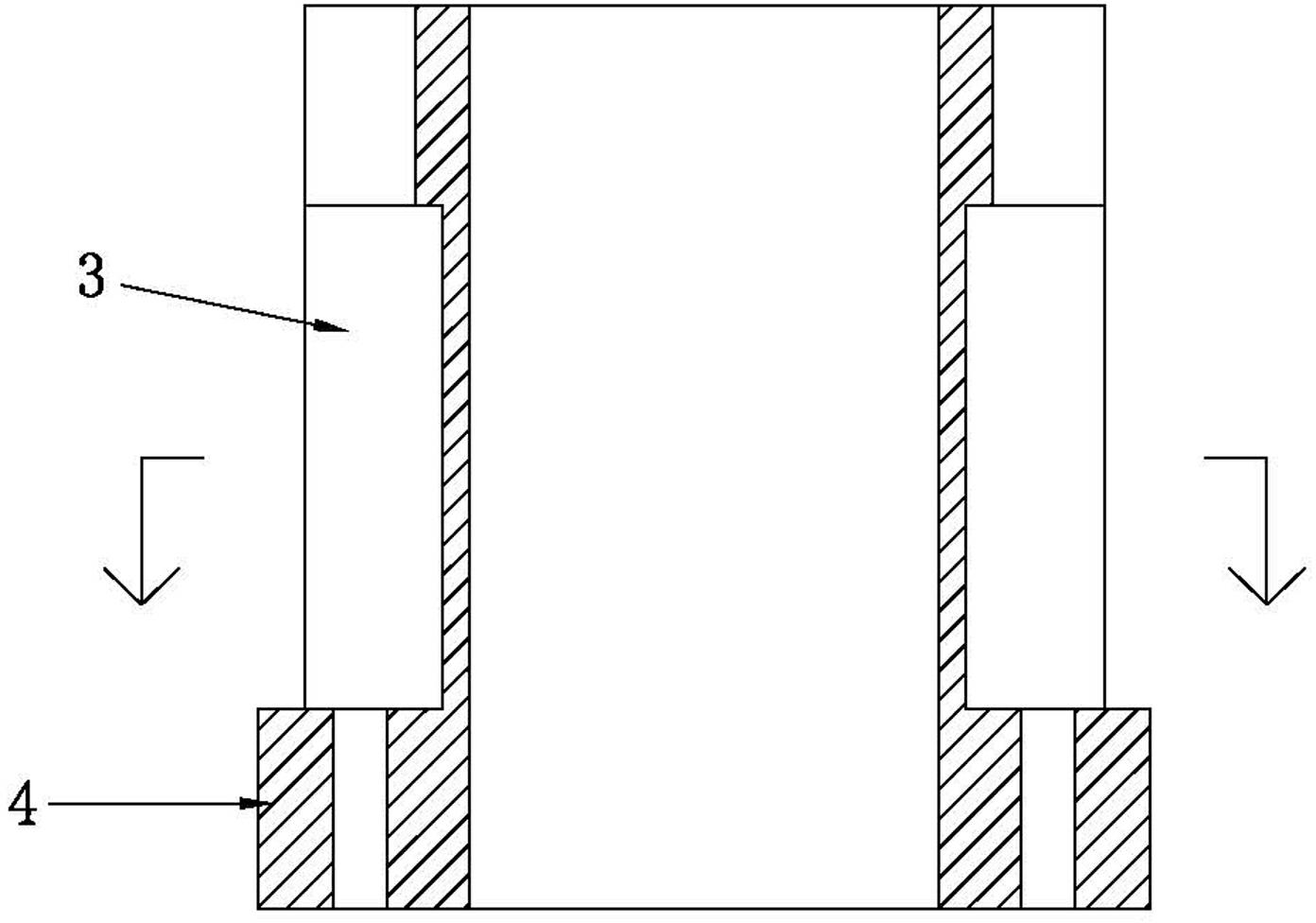

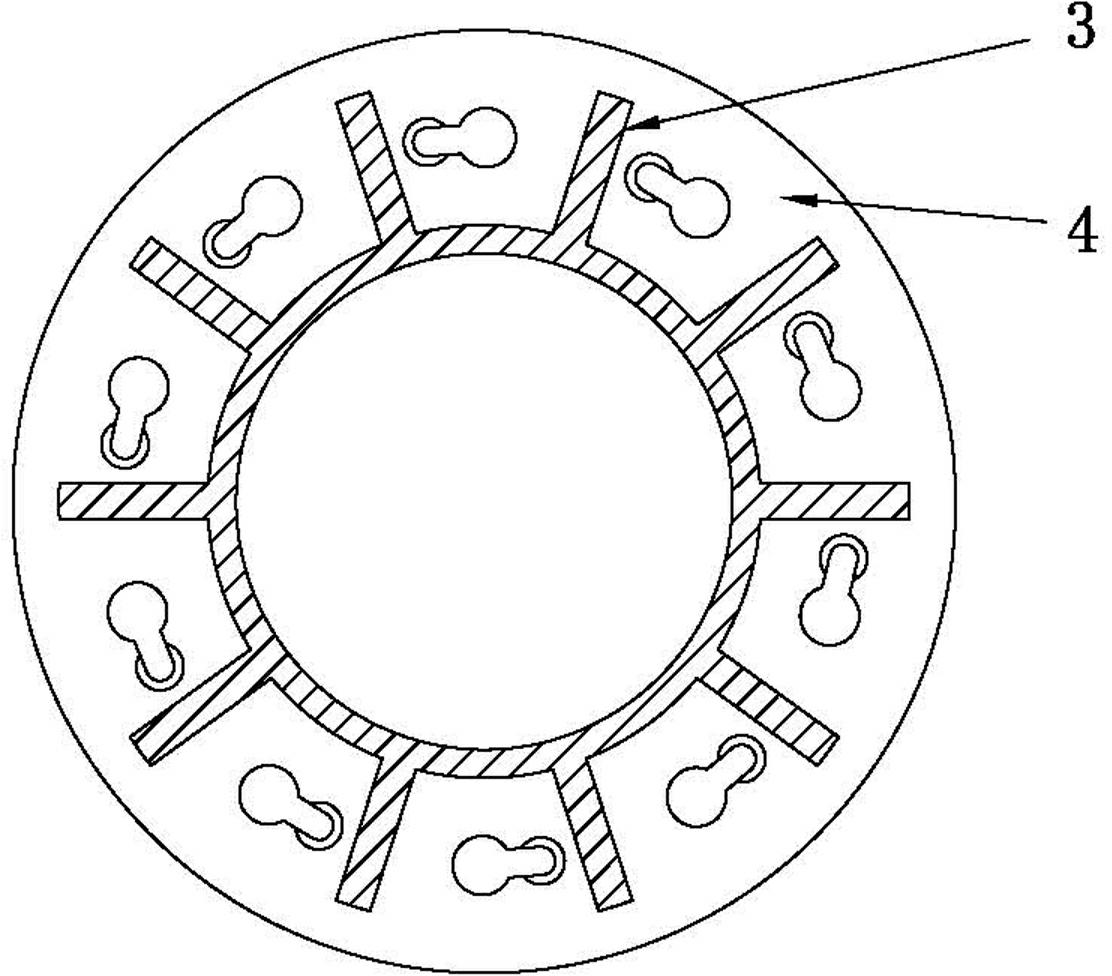

[0014] refer to figure 1 , figure 2 , image 3 , prestressed concrete pipe pile anticorrosion joint, including end plate 1 and connecting flange 2, rib frame 3 is arranged on connecting flange 2, and connecting plate 4 connected with pipe pile is arranged at one end of rib frame, and end plate 1 is provided with A number of screw holes are provided, and the connecting flange 2 is provided with a number of bolt insertion positions 8 corresponding to the screw holes 4 .

[0015] As shown in the figure, in order to facilitate the installation of bolts, the flange at the bolt insertion position is provided with an opening groove 5 communicating with the bolt insertion position.

[0016] The connecting parts of the end plate and the connecting flange are coated with different anti-corrosion coatings for different corrosive environments, and the anti-corrosion coatings will not be damaged by friction and extrusion during the process of driving the pipe pile into the ground.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com