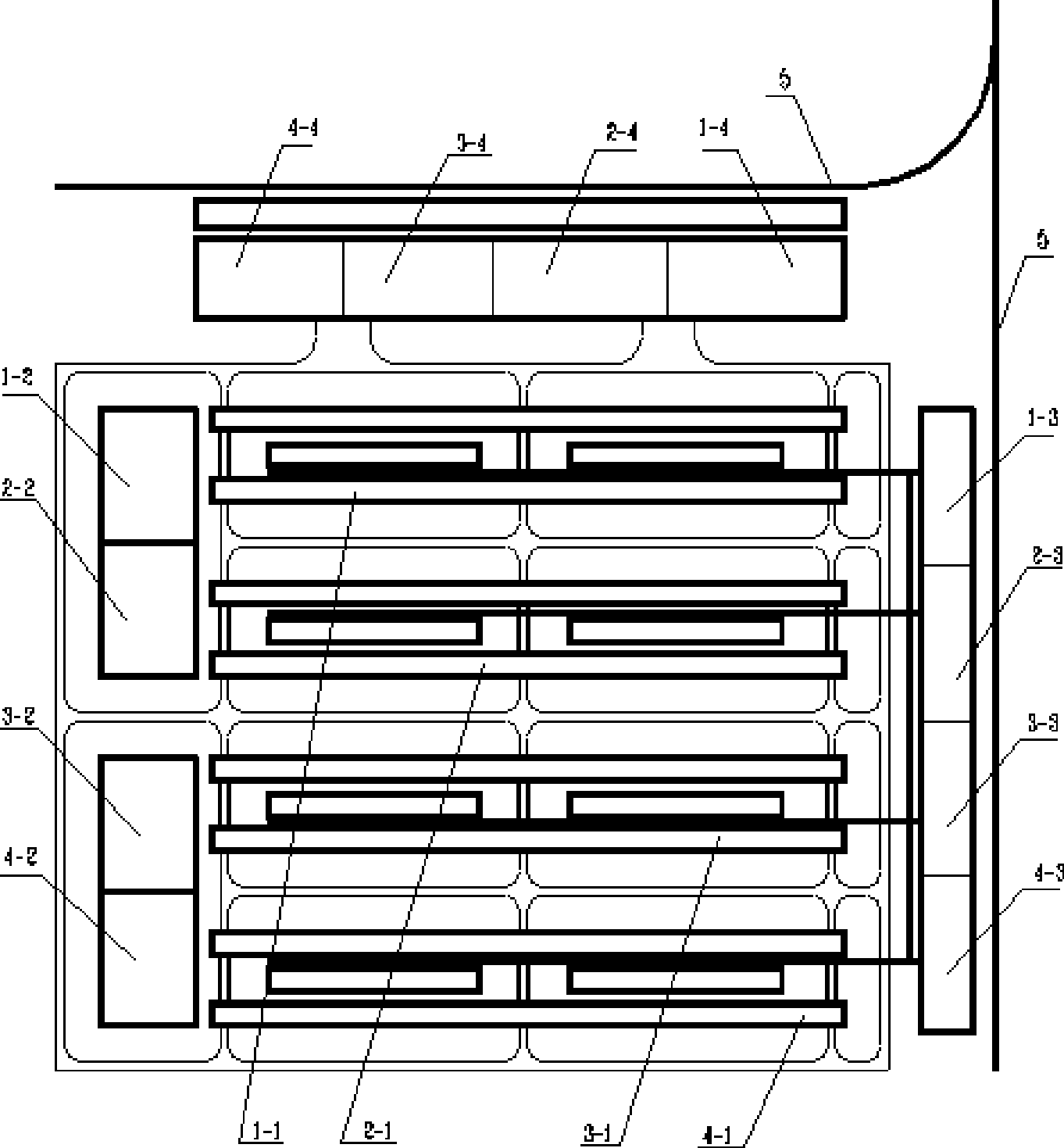

Electrolytic aluminum plant collocation form of series layout

A series, aluminum plant technology, applied in the field of general layout of industrial enterprises, can solve the problem of no longer adapting to the requirements of its production and development, and achieve the effect of saving the length of engineering pipelines, being beneficial to production and construction, and reducing the floor space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The embodiment of the present invention: design and layout a planned electrolytic aluminum plant, and divide it into four production series. First, the electrolysis production area 1-1 of the first production series is arranged. This area includes two electrolysis workshops, the flue gas purification facility in the middle, and the alumina storage bin and feeding system. At one end of the electrolysis production area 1 is arranged. —2. Arrange the alumina unloading, storage and transportation area 1-3 at the other end, which is close to the railway transportation system 5, so that the alumina raw material enters the feeding system in the middle of the workshop from the end of the electrolysis workshop, and the transportation distance The shortest; the casting and storage areas 1-4 are arranged in parallel with the electrolysis production area 1-1, and are close to the transportation railway system 5.

[0013] Secondly, the electrolysis production area 2-1 of the second prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com