Numerical control machine tool wear monitoring method

A tool wear and CNC machine tool technology, applied in the field of real-time monitoring and online tool wear status, can solve problems such as affecting the normal processing of the machine tool, changing the structure of the machine tool, and not being a fixed value, so as to monitor the tool wear status in real time, improve the application range, Easy to install effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing:

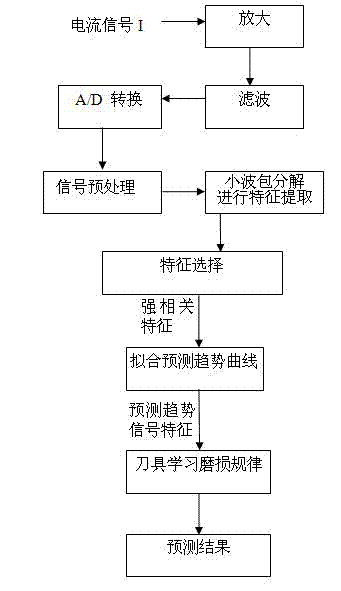

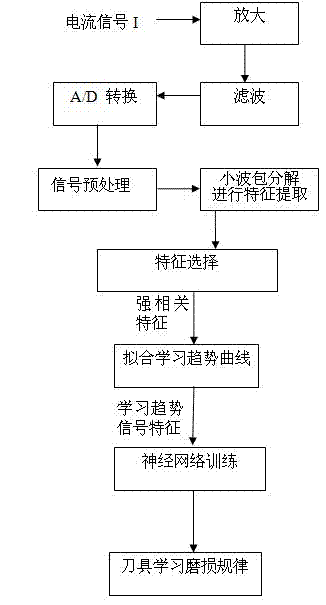

[0022] The tool wear state monitoring method of the present invention realizes the monitoring of the tool wear VB by acquiring the current signal of the machine tool drive motor, a series of signal processing and feature extraction selection processes, and finally through the tool wear monitoring process.

[0023] First, establish the tool learning wear law in the learning library through the following steps:

[0024] (1) Use the Hall current sensor to measure the three-phase output current of the drive motor of the CNC machine tool respectively;

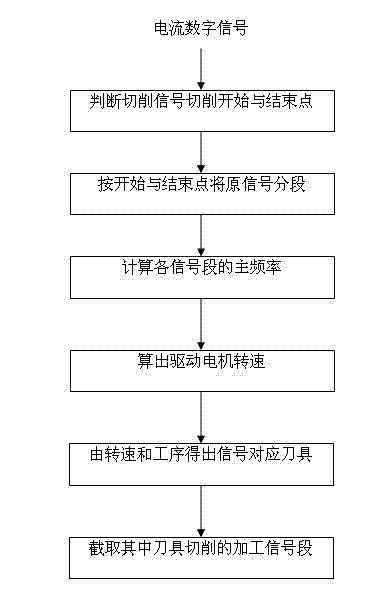

[0025] (2) The measured output current is respectively amplified, filtered and A / D converted to obtain a current digital signal, which is the processing signal;

[0026] (3) Preprocessing the processing signal to obtain the current signal segment when the learning tool is cutting;

[0027] The processing signals obtained throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com