Polypropylene composite material and preparation method thereof

A composite material, polypropylene pellet technology, applied in the field of polymer materials, can solve the problems of reducing the oxidation resistance and hydrolysis resistance of the material, destroying the interface between the fiber and the polypropylene resin, reducing the mechanical properties of the material, etc., to achieve long-term water resistance. effect of hydrolysis properties, excellent mechanical properties, good mechanical properties and hydrolysis resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

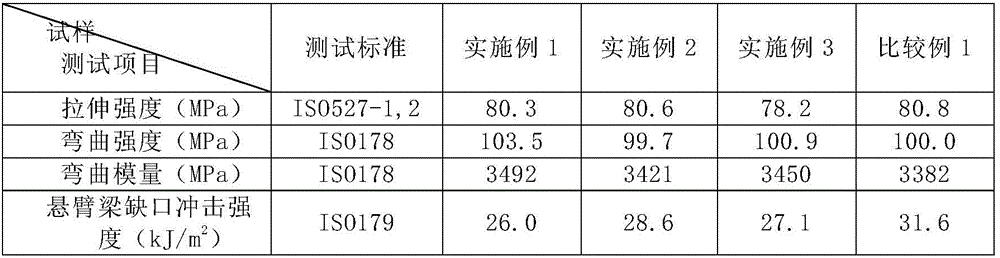

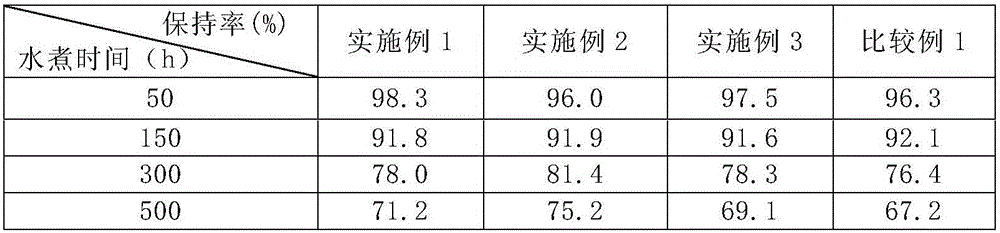

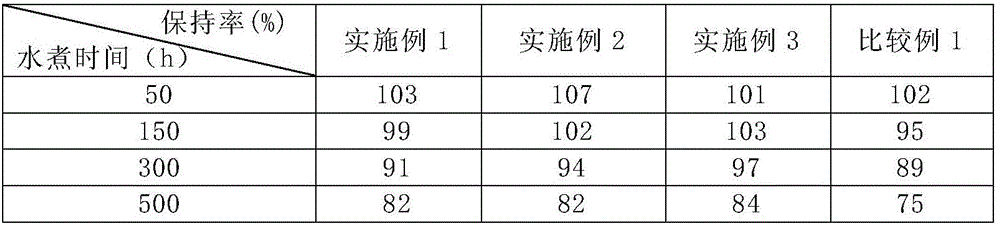

Examples

preparation example Construction

[0064] Specifically, the preparation method of the polypropylene composite material of the present invention comprises the following steps:

[0065] (1) According to the weight portion of the present invention, after mixing polypropylene, compatibilizer, antioxidant and lubricant through a high mixer, they are added to the extruder for melt mixing, and the temperature range of the extruder is 180 ~250℃;

[0066] (2) impregnating the continuous fiber with the molten polypropylene mixture in the dipping tank, and then drawing, cooling and pelletizing to obtain the long-fiber-reinforced polypropylene masterbatch;

[0067] (3) According to the parts by weight of the present invention, after mixing polypropylene, antioxidant and fluoropolymer through a high-speed mixer, they are added to an extruder for melting and mixing, and then cooled and pelletized to obtain the modified Non-toxic polypropylene pellets;

[0068] (4) According to the parts by weight of the present invention, ...

Embodiment 1

[0077] 47 parts by weight of polypropylene, 2 parts by weight of maleic anhydride grafted polypropylene compatibilizer, 0.5 part by weight of hindered phenolic antioxidant 1010 (purchased from Rianlon (Rianlon) company), 0.3 part by weight of phosphite antioxidant Oxygen 168 (purchased from Rianlon (Rianlon) company) and 0.2 parts by weight of calcium stearate lubricant were mixed for 15 minutes through a high mixer, and then added to a twin-screw extruder for melting and mixing, and the temperature range of the extruder was 180~230℃.

[0078] The molten polypropylene mixture was impregnated with 50 parts by weight of continuous non-alkali glass fibers in an impregnation tank. After drawing, cooling and pelletizing, long fiber reinforced polypropylene masterbatches are obtained. In this masterbatch, the glass fiber content is 50%, and the length is 10mm.

[0079] 93.5 parts by weight of polypropylene, 0.25 parts by weight of hindered phenolic antioxidant 1010, 0.25 parts by ...

Embodiment 2

[0082] 95.5 parts by weight of polypropylene, 0.25 parts by weight of hindered phenolic antioxidant 1010, 0.25 parts by weight of phosphite antioxidant 168 and 2 parts by weight of polyvinylidene fluoride were mixed for 15 minutes by a high mixer, and then added to the twin-screw Melting and mixing in the extruder, the temperature range of the extruder is 180-230°C. Modified polypropylene pellets are obtained after cooling and pelletizing.

[0083] The long-fiber reinforced polypropylene masterbatch obtained in Example 1 and the modified polypropylene pellets obtained in Example 2 were added to a high mixer in a ratio of 30:70 and mixed for 5 minutes to obtain the polypropylene composite Material. In this composite, the glass fiber content is 15% and the polyvinylidene fluoride content is 1.4%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface energy | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com