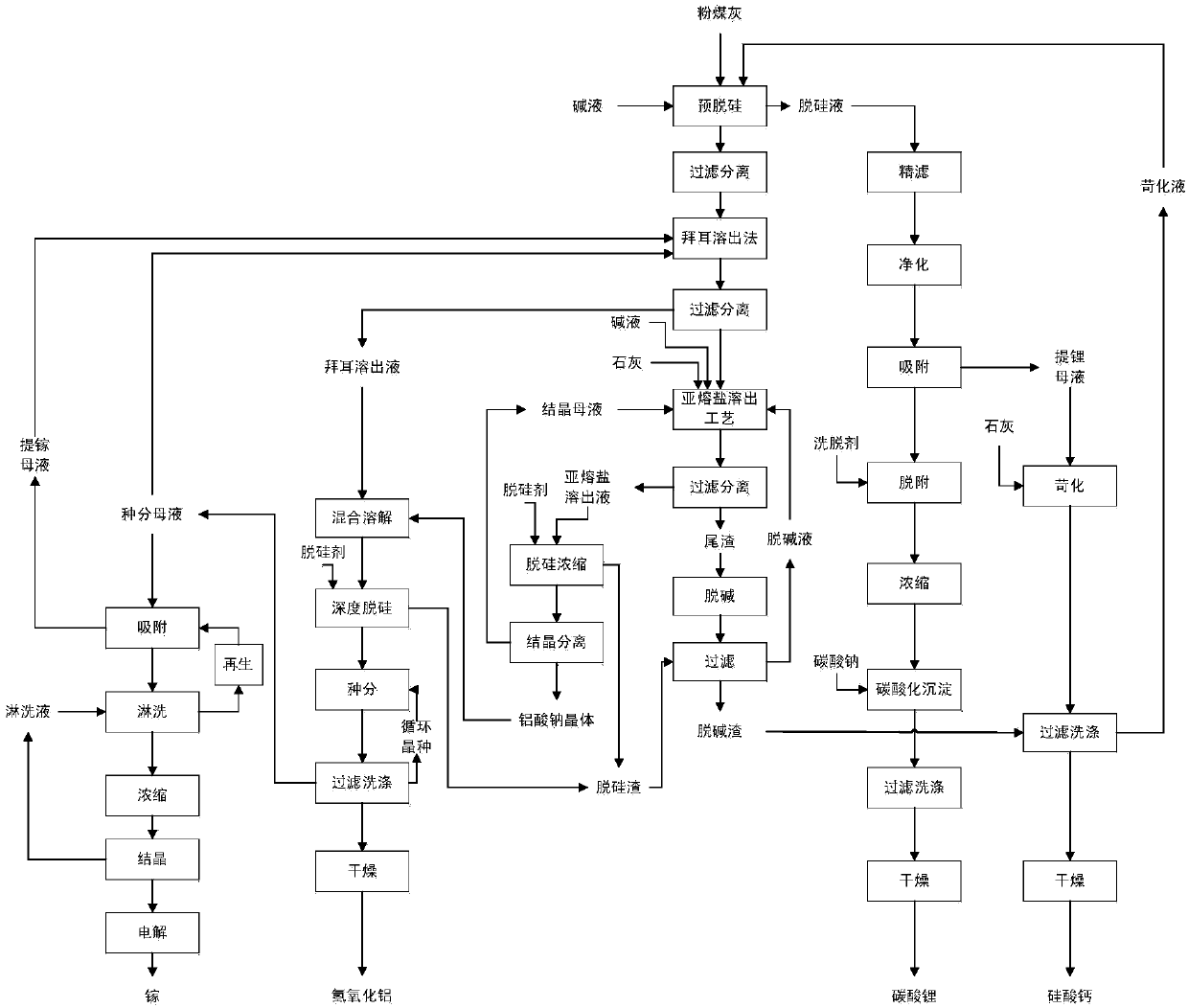

Extraction method for cooperating with aluminum-silicon-lithium-gallium combination method in coal ash

A fly ash, aluminum-silicon technology, applied in silicate, alkaline earth metal silicate, improvement of process efficiency, etc., can solve the problems of high energy consumption, long treatment process, failure to fully utilize lithium resources, etc. The effect of high extraction selectivity, low cost and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

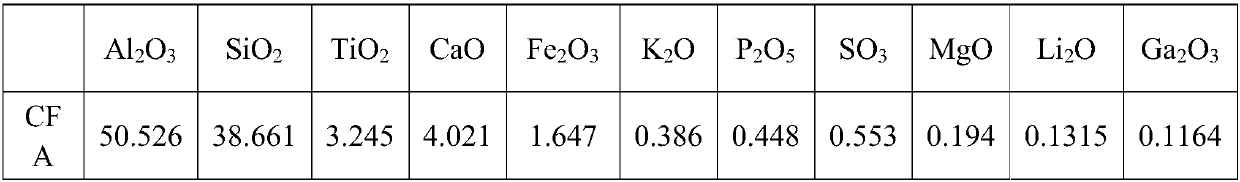

[0050] (1) Pre-desilication reaction: the fly ash described in Table 1 is mixed with 15% sodium hydroxide solution in mass fraction, and alkali dissolution reaction is carried out in the reactor, and the liquid-solid ratio of lye and fly ash is 3:1, the temperature of the alkali dissolution reaction is 90°C, the process of the alkali dissolution reaction is accompanied by stirring, the stirring speed is 300r / min, the time of the alkali dissolution reaction is 120min, and the desiliconization solution (lithium ion concentration 110ppm) and the Mixed slurry of silica fume and coal ash; then separated by filtration

[0051] (2) Bayer stripping: mix the desiliconized fly ash obtained in step (1) with the mother liquor for extracting gallium. The first Bayer stripping process uses a sodium aluminate solution with a caustic ratio of 3.5 for stripping, and the liquid-solid ratio is 2:1. , the reaction temperature is 200°C, and the reaction time is two hours; after the reaction, the B...

Embodiment 2

[0058] (1) Pre-desilication reaction: the fly ash described in Table 1 and the mass fraction are mixed with 20% sodium hydroxide solution, and the pre-desilication reaction is carried out in the reactor, the liquid-solid ratio of lye and fly ash The temperature is 2:1, the temperature of the alkali dissolution reaction is 100°C, the alkali dissolution reaction is accompanied by stirring, the stirring speed is 600r / min, the time of the alkali dissolution reaction is 90min, and the desiliconization solution (lithium ion concentration 140ppm) and Mixed slurry of desiliconized fly ash; separated by filtration

[0059] (2) Bayer stripping: mix the desiliconized fly ash obtained in step (1) with the mother liquor for extracting gallium. The first Bayer stripping process uses a sodium aluminate solution with a caustic ratio of 3.5 for stripping, and the liquid-solid ratio is 2:1. , the reaction temperature is 220°C, and the reaction time is two hours; after the reaction, the Bayer el...

Embodiment 3

[0066] (1) Pre-desilication reaction: the fly ash described in Table 1 and the mass fraction are mixed with 10% sodium hydroxide solution, and the pre-desilication reaction is carried out in the reactor, the liquid-solid ratio of lye and fly ash 4:1, the temperature of the alkali dissolution reaction is 120°C, the alkali dissolution reaction is accompanied by stirring, the stirring speed is 600r / min, the time of the alkali dissolution reaction is 150min, and the desiliconization solution (lithium ion concentration 70ppm) and Mixed slurry of desiliconized fly ash; separated by filtration

[0067](2) Bayer stripping: mix the desiliconized fly ash obtained in step (1) with the mother liquor for extracting gallium. The first Bayer stripping process uses a sodium aluminate solution with a caustic ratio of 3.5 for stripping, and the liquid-solid ratio is 2:1. , the reaction temperature is 180°C, and the reaction time is two hours; after the reaction, the Bayer eluate and Bayer eluat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com