Zero-formaldehyde wood adhesive and preparation method thereof

A wood adhesive, zero-formaldehyde technology, applied in the field of zero-formaldehyde wood adhesive and its preparation, can solve the problems of formaldehyde pollution, harm to health, unsatisfactory, etc., achieve good bonding performance and water resistance, solve the problem of formaldehyde pollution, The effect of good development momentum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

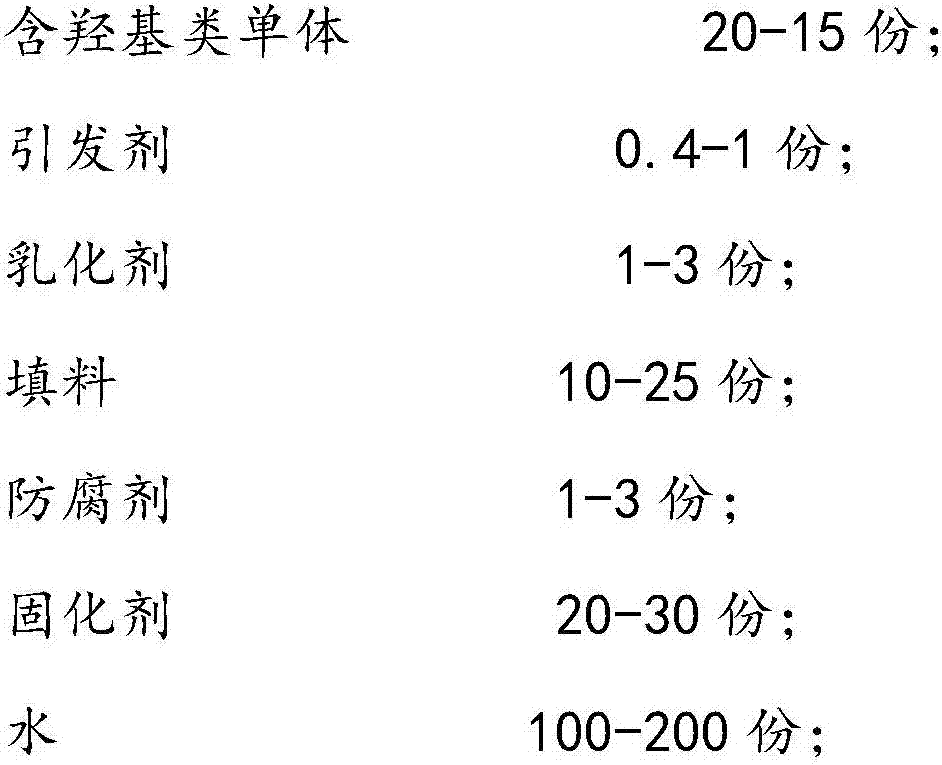

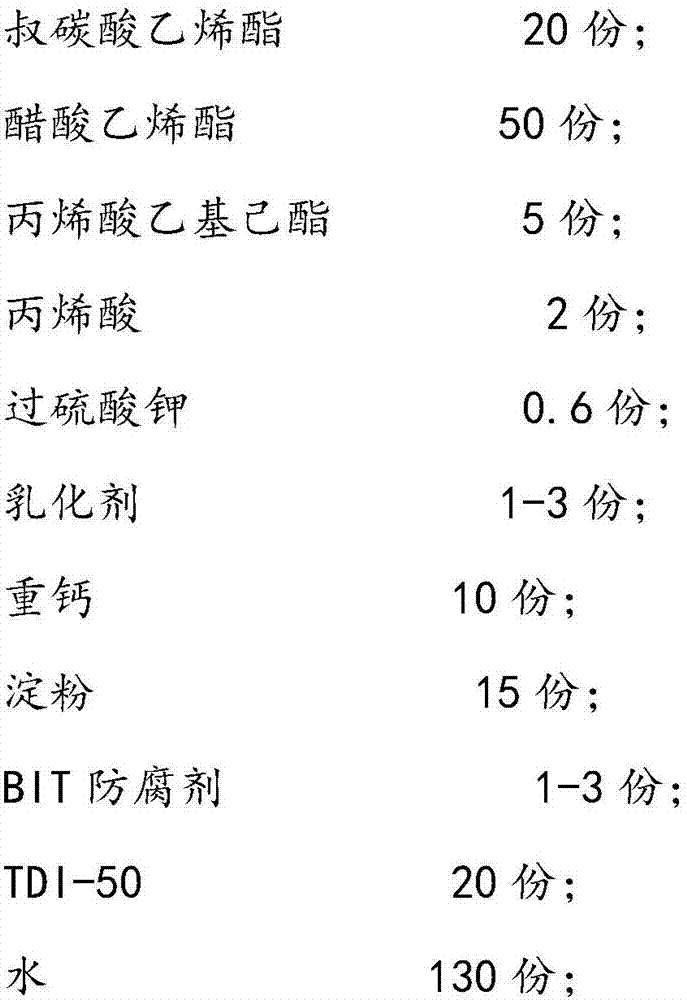

[0029] A kind of zero-formaldehyde wood adhesive, its formula is calculated as:

[0030]

[0031] Both starch and heavy calcium are fillers, and the filler composition includes one or more mixtures of starch, heavy calcium, light calcium, etc.;

[0032] TDI-50 is toluene diisocyanate.

[0033] (1) Add 4 / 5 parts by mass of vinyl tertiary carbonate, vinyl acetate, ethylhexyl acrylate, and acrylic acid monomers to the emulsifier in turn according to their hydrophilicity to form a stable milky white emulsification liquid.

[0034] (2) After mixing the remaining 1 / 5 parts by mass of each monomer, add it into a reaction kettle that has been heated to 60-65°C, add 1 / 3 parts by mass of potassium persulfate solution, and keep warm for 0.5-1h.

[0035] (3) When the temperature is raised to 75-80°C until blue fluorescence appears in the system, add an appropriate amount of pH regulator, and start to drop the emulsion and the remaining 2 / 3 parts by mass of the initiator, and control ...

Embodiment 2

[0039] A kind of zero-formaldehyde wood adhesive, its formula is calculated as:

[0040]

[0041] (1) Add 4 / 5 parts by mass of styrene, butyl acrylate, hydroxypropyl acrylate, and acrylic acid monomers into the emulsifier in turn according to their hydrophilicity to emulsify to form a stable milky white emulsion.

[0042] (2) After mixing the remaining 1 / 5 parts by mass of each monomer, add it into a reaction kettle that has been heated to 60-65°C, add 1 / 3 parts by mass of potassium persulfate solution, and keep warm for 0.5-1h.

[0043] (3) When the temperature is raised to 75-80°C until blue fluorescence appears in the system, add an appropriate amount of pH regulator, and start to drop the emulsion and the remaining 2 / 3 parts by mass of the initiator, and control the dropping time to 4-6h.

[0044] (4) After the emulsion is added dropwise, raise the temperature to 85°C, keep it warm for 30 minutes, and carry out vacuum treatment. The vacuum degree in the kettle is contro...

Embodiment 3

[0047] A kind of zero-formaldehyde wood adhesive, its formula is calculated as:

[0048]

[0049] (1) Add 4 / 5 parts by mass of vinyl butyrate, vinyl acetate, hydroxyethyl methacrylate, and acrylic acid monomers to the emulsifier in sequence according to their hydrophilicity to form a stable milky white emulsion.

[0050] (2) After mixing the remaining 1 / 5 parts by mass of each monomer, add it into a reaction kettle that has been heated to 60-65°C, add 1 / 3 parts by mass of potassium persulfate solution, and keep warm for 0.5-1h.

[0051] (3) When the temperature is raised to 75-80°C until blue fluorescence appears in the system, add an appropriate amount of pH regulator, and start to drop the emulsion and the remaining 2 / 3 parts by mass of the initiator, and control the dropping time to 4-6h.

[0052] (4) After the emulsion is added dropwise, raise the temperature to 85°C, keep it warm for 30 minutes, and carry out vacuum treatment. The vacuum degree in the kettle is contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com