A process for wood-plastic composite manufacturing of formaldehyde-free bending and gluing parts

A technology of wood-plastic composites and parts, which is applied in the direction of manufacturing tools, wood processing appliances, and the joining of wooden veneers. It can solve the problems of inability to make curved furniture parts, reduce the bending performance of veneers, and affect the environmental protection of furniture, etc. problems, to achieve the effect of improving the surface decoration effect, solving the problem of formaldehyde pollution, and low requirements for equipment and molds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] (1) Preparation of "C" type chair back curved parts: According to the large radius of curvature of the part (650mm), select Eucalyptus veneer, the thickness of the veneer is 1.5mm, and the moisture content of the veneer is 10%, and glued on the veneer The surface is processed by rolling holes, the pores are irregularly distributed, and the number of pores is 20-30 / cm 2 Between, the veneer is cut into specifications length × width: 400 × 250mm;

[0016] (2) Cutting the prefabricated polyethylene plastic film to a size 2mm larger in width than the veneer;

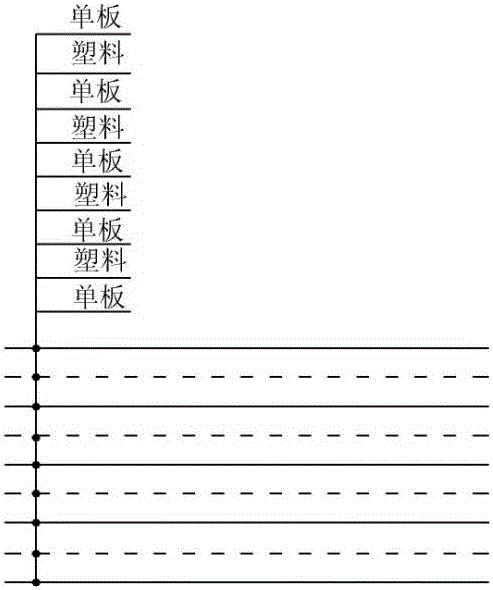

[0017] (3) According to the thickness of the part is 15mm, combined with the thickness of the veneer, plastic film and the compression rate of the pressurization and bending process, the layers of 11 layers of veneer and 10 layers of plastic film are alternately stacked to form the billet. After the billet is formed, the upper and lower sides for the veneer;

[0018] (4) Place the slab in a hard mold made of "C" type...

Embodiment 2

[0022] (1) Preparation of "L" shaped chair back and seat integrated curved parts: According to the large radius of curvature of the part (100mm), birch veneer is selected, the thickness of the veneer is 1.5mm, the moisture content of the veneer is 10%, and Carry out rolling hole treatment on the veneer glued surface, the pores are irregularly distributed, and the number of pores is 20-30 / cm 2 , the veneer is cut into specifications length × width: 1000 × 400mm;

[0023] (2) Cutting the prefabricated polyethylene plastic film to a size 2mm larger in width than the veneer;

[0024] (3) According to the thickness of the part is 15mm, combined with the thickness of the veneer, plastic film and the compression rate of the pressurization and bending process, the layers of 11 layers of veneer and 10 layers of plastic film are alternately stacked to form the billet. After the billet is formed, the upper and lower sides for veneer

[0025] (4) Place the slab in a hard mold made of "L...

Embodiment 3

[0029] (1) Preparation of curved parts of armrest of "U" leisure chair: according to the small radius of curvature (60mm) of the part, choose ash veneer, the thickness of the veneer is 1.5mm, and the moisture content of the veneer is 12%. The gluing surface of the board is processed by rolling holes, the pores are irregularly distributed, and the number of pores is 20-30 / cm 2 Between, the veneer is cut into a specification length×width: 800×220mm;

[0030] (2) Cutting the prefabricated polyethylene plastic film to a size 2mm larger in width than the veneer;

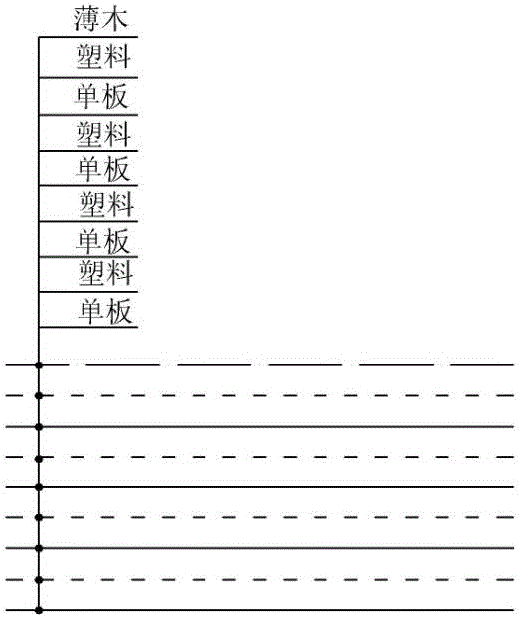

[0031] (3) According to the thickness of the part is 10mm, combined with the thickness of the veneer and plastic film and the compression rate of the pressurization and bending process, the layers of 9 layers of veneer and 8 layers of plastic film are alternately stacked to form the billet. After the billet is assembled, the upper and lower sides for veneer

[0032] (4) Place the slab in a hard male and female mold made...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com