Patents

Literature

30results about How to "Improve the surface decoration effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

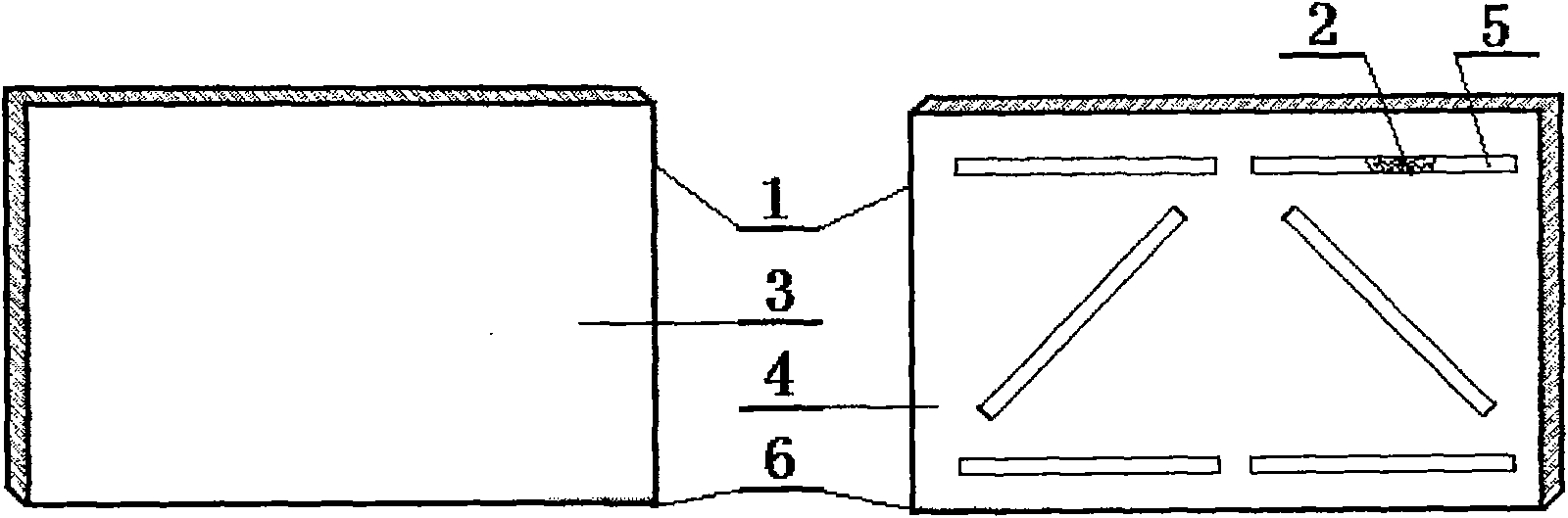

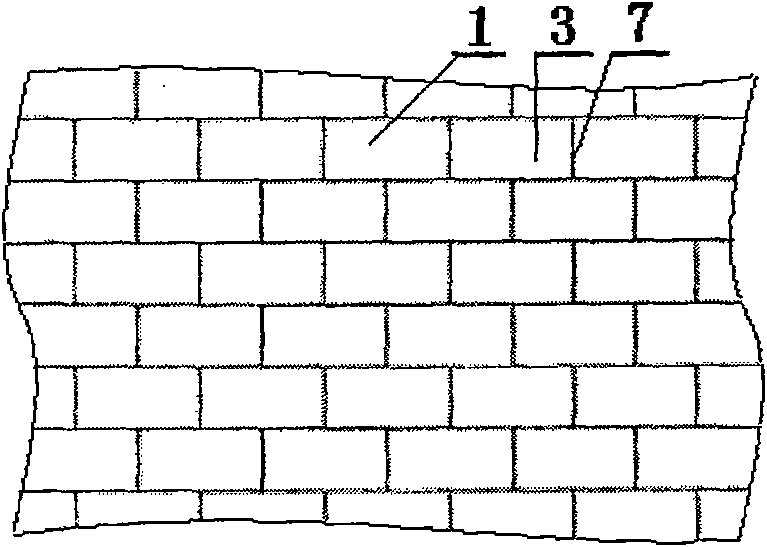

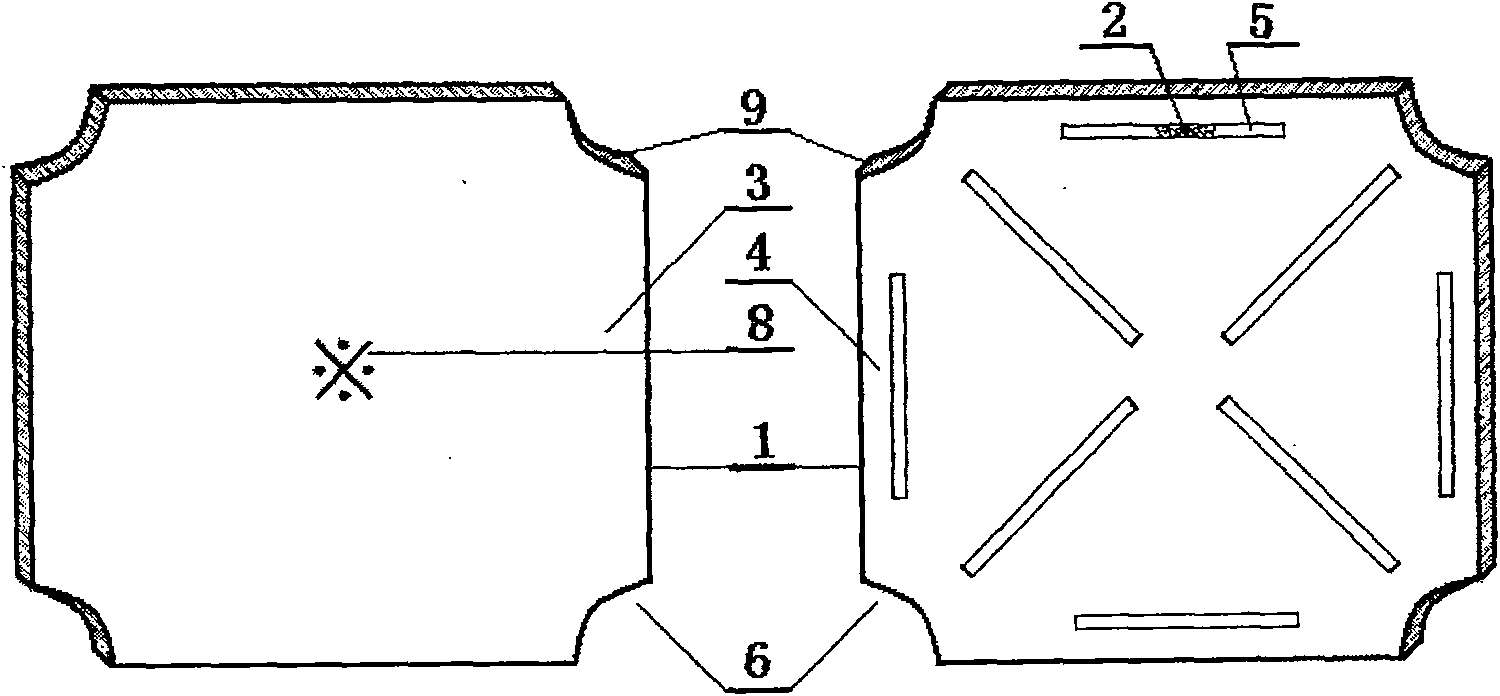

Foamed ceramics energy saving and heat preservation decorative wall brick and manufacture method thereof

InactiveCN101560111ALow thermal conductivityLow densityCeramic materials productionCeramicwareBrickSlurry

The invention discloses a foamed ceramics energy saving and heat preservation decorative wall brick and a manufacture method thereof, including the steps of conducting ball milling on 15-65 percent wt of industrial residues, 10-45 percent wt of plastic clay, 15-60 percent wt of solvent, 10-45 percent wt of pore-forming agent with the fineness being 1-100mum and proper amount of water to form slurry; spray drying or dehydration and clay preparation, and forming powder material or clay segment through staleness; and implementing pressure forming to make billet which is burned under heat preservation at temperature of 1140-1240 DEG C to finally form the foamed ceramics wall brick. The wall brick can be used not only for the heat preservation and decoration of external walls, but also for indoor heat preservation and decoration, and the external wall and the indoor space can realize the organic combination of uniform heat preservation and decoration, which agrees with the development direction of heat preservation material industry of external walls. The wall brick has the advantages of: I. high temperature resistance, acid and alkali-resistance, good chemical stability, no ageing, strong durability, long service life, no generation of heat channel and good adhesive fixity; and II. difficult water seepage and crack, strong anti-corrosion capacity, uneasy deformation and damage, simplification of mounting, laying and sticking procedures, convenience for construction, relief of labor intensity and decrease of material consumption quantity.

Owner:吴汉阳

Composition and method for finishing surface of preservative-treated wood engineering material used outdoors

InactiveCN103013328AResist decayResist mildewAnti-corrosive paintsCoating impregnationLoss rateOrganic film

The invention relates to a composition and method for finishing thwe surface of a preservative-treated wood engineering material used outdoors. The composition comprises an organo-silicon polymer, a holy polymer resin, a titanic oxide, an organic solvent component and a monomer mixture. An organic film is formed on the surface of the preservative wood engineering material through a surface finishing technology so that the surface ornamental feature of the wood engineering material is increased, simultaneously the preservative wood engineering material is endowed with good water-resisting property and weather resistance property, the outdoor use performance of the preservative wood engineering material is increased, the service life of the preservative wood engineering material is effectively prolonged, and the damage to environments is reduced. The preservative wood engineering material obtained by the invention has the advantages that the loss rate of an effective constituent copper is reduced from above 90% to 8%-15%, wherein the loss rate of the copper in an untreated material is above 90%, and after aging tests, the chromaticity indexes delta a*, delta b*, luminosity equation delta L* and chromatism delta E*of the surface of the treated material are obviously less than that of the untreated material, the weight loss rate of the treated material is 5%-8%, and the strength loss of the treated material is 5%-12%.

Owner:TIANJIN UNIV OF SCI & TECH

Composition for chemical Cu plating onto timber surface and the chemical Cu plating process

InactiveCN1974840AImprove the surface decoration effectLiquid/solution decomposition chemical coatingChemical reactionCopper coating

The present invention discloses one kind of composition for chemical copper plating onto timber surface and the chemical copper plating process. The composition contains copper compound, complexing agent and reductant. The chemical copper plating process is to set the timber in the composition solution, so that copper ion is reduced through chemical reaction and deposited homogeneously onto the surface of the timber and the timber surface possesses metal decoration effect and conducting performance. The present invention can reach copper coating thickness over 3.5 microns and square resistivity as low as 0.06 ohm, being comparable with copper foil.

Owner:BEIJING FORESTRY UNIVERSITY

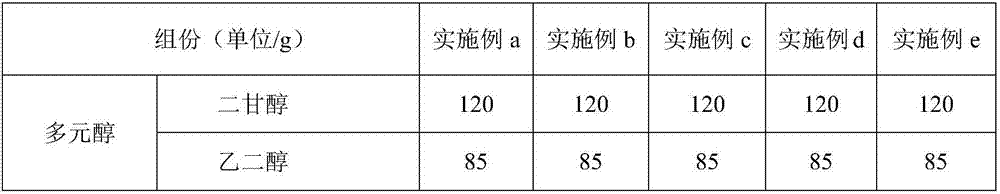

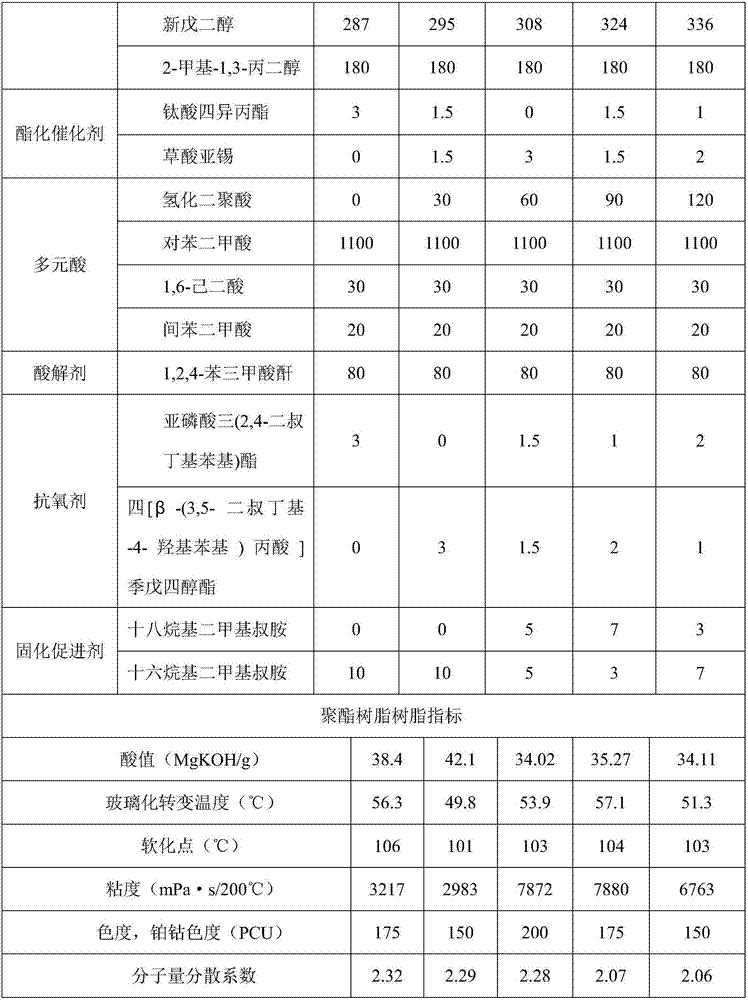

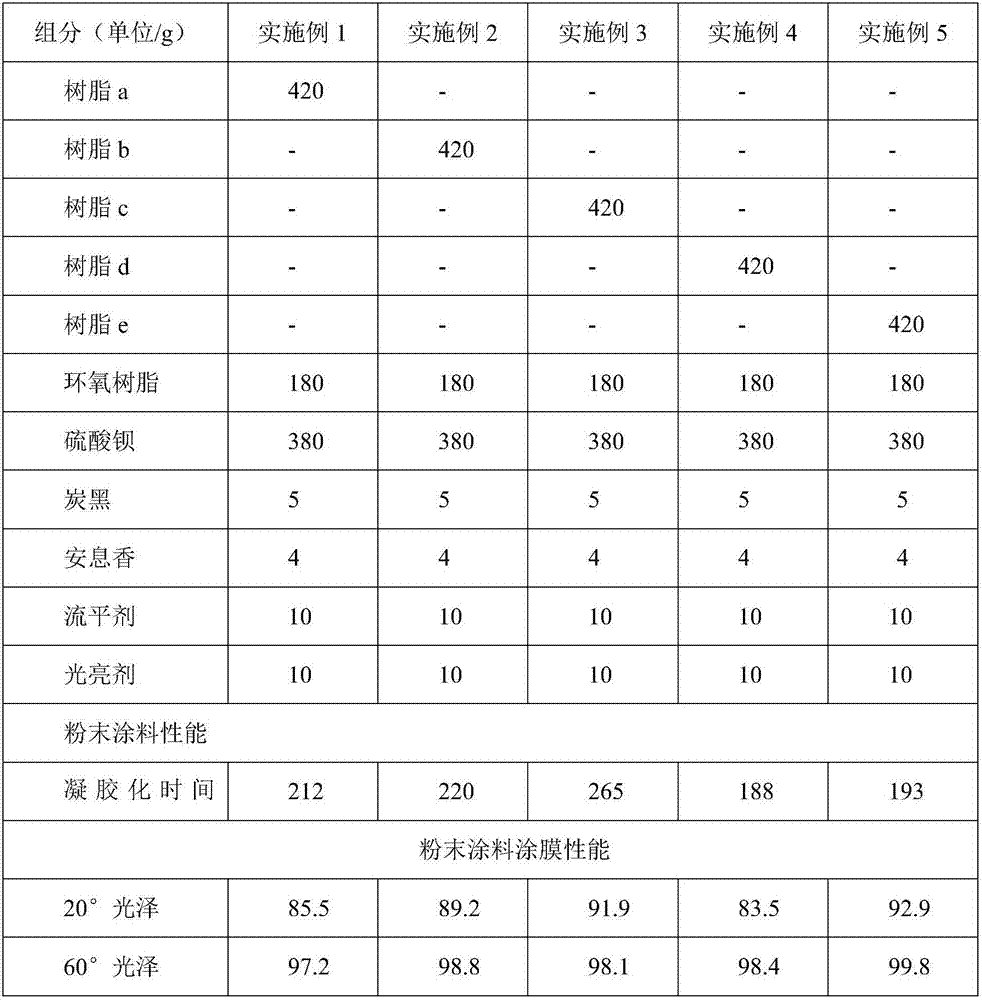

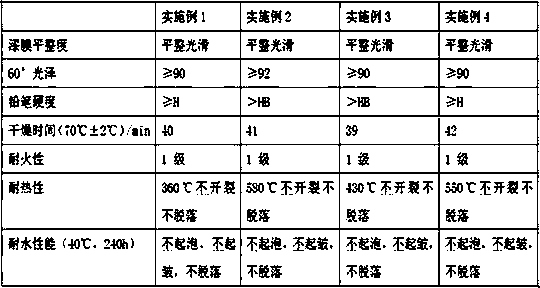

Epoxy cured polyester resin used for powdery paint having high surface decorative performance and high water resistance and preparation method thereof

ActiveCN107254240AThe temperature is 50.0~54.0℃, the rotational viscosity is highIncrease viscosityPowdery paintsPolyester coatingsEpoxyDistillation

The invention relates to epoxy cured polyester resin used for a powdery paint having high surface decorative performance and high water resistance and a preparation method thereof. The provided polyester resin has appropriate glass-transition temperature, a prepared powdery paint film has excellent dynamic mechanical properties, high surface decoration performance and high water resistance. The polyester resin is prepared by melt phase polycondensation of the raw materials of polyol, polyprotic acid, an acidulate agent, an esterification catalyst, an anti-oxidant and a curing accelerator. The method of the polyester resin comprises the following steps: 1) the polyol is delivered into a reaction kettle at a needed ratio, rapid heating esterification is carried out, water is generated, and is removed via distillation; 2) temperature is increased gradually, and an obtained material is maintained to be clear; 3) sample examination is carried out; 4) negative pressure polycondensation is carried out; and 5) cooling is carried out, the antioxidant and the curing accelerator are added, stirring dispersing is carried out, and an obtained product is cooled, and is collected.

Owner:ZHEJIANG CHUANHUA TIANSONG NEW MATERIAL CO LTD

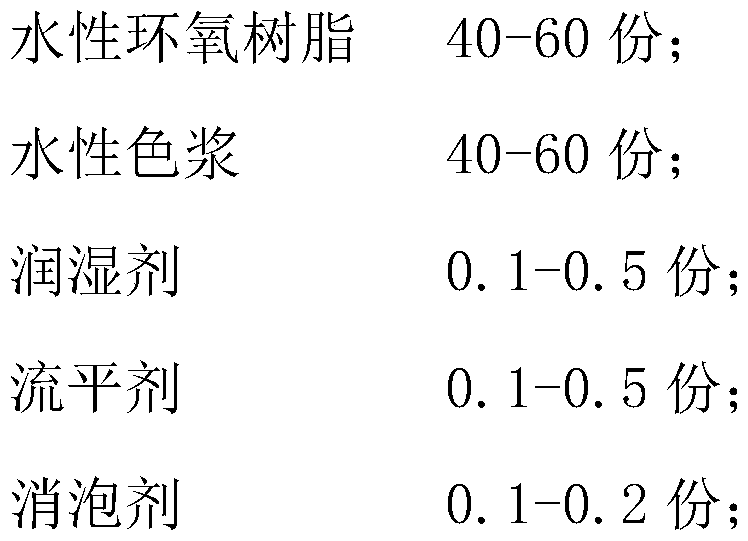

Dual-component water-based bright colorized tile decorative crack-sealer

The invention discloses a dual-component water-based bright colorized tile decorative crack-sealer. The decorative crack-sealer is prepared from an ingredient A and an ingredient B by mixing according to a weight ratio of 1: 1-2. The ingredient A comprises, by weight, 70-90 parts of epoxy resin, 5-20 parts of an emulsifier, 0.5-2 parts of a rheology modifier, 3-20 parts of a flexible additive and 2-4 parts of a surfactant. The ingredient B comprises, by weight, 50-90 parts of a curing agent, 10-30 parts of pigments with different colors and fillers, 4-30 parts of deionized water, 4-10 parts of a brightening agent, 0.1-1.5 parts of a dispersant, 1-5 parts of a crack-resistant agent, 0.1-2 parts of a thickening agent, 0.1-1.5 parts of a dispersant, 0.25-2 parts of an antifoaming agent, 0.5-2 parts of a leveling agent, 1-5 parts of an anti-settling agent and 2-6 parts of an anti-sagging agent. The decorative crack-sealer has high brightness and high hardness, does not mildew, blacken, shrink, collapse, sag and fall, can resist water, oil stain, acid, alkali, etch, scrubbing and water immersion, has good adhesion and has excellent aesthetic feeling.

Owner:SHANGHAI YOUJIN COMPOSITE NEW MATERIAL CO LTD

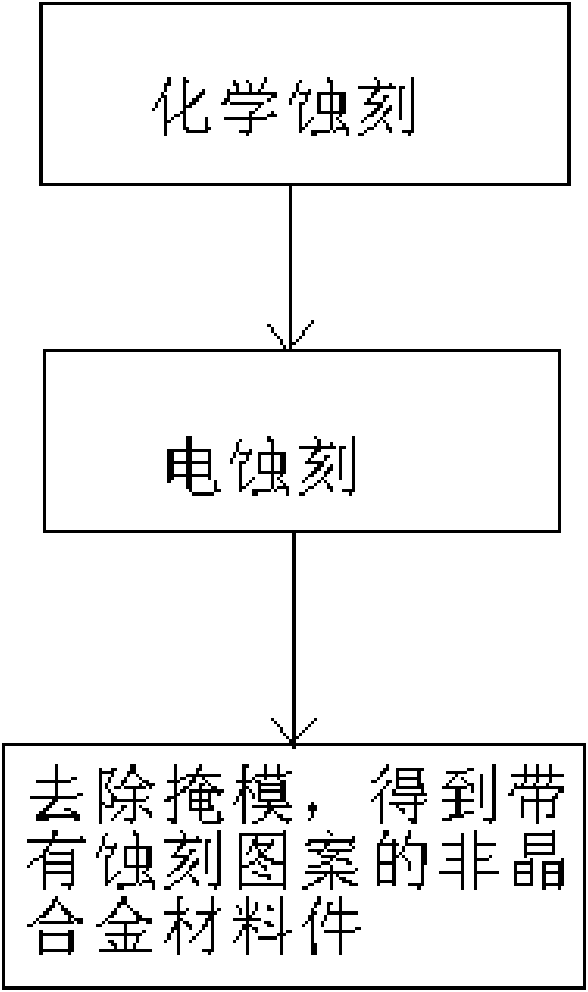

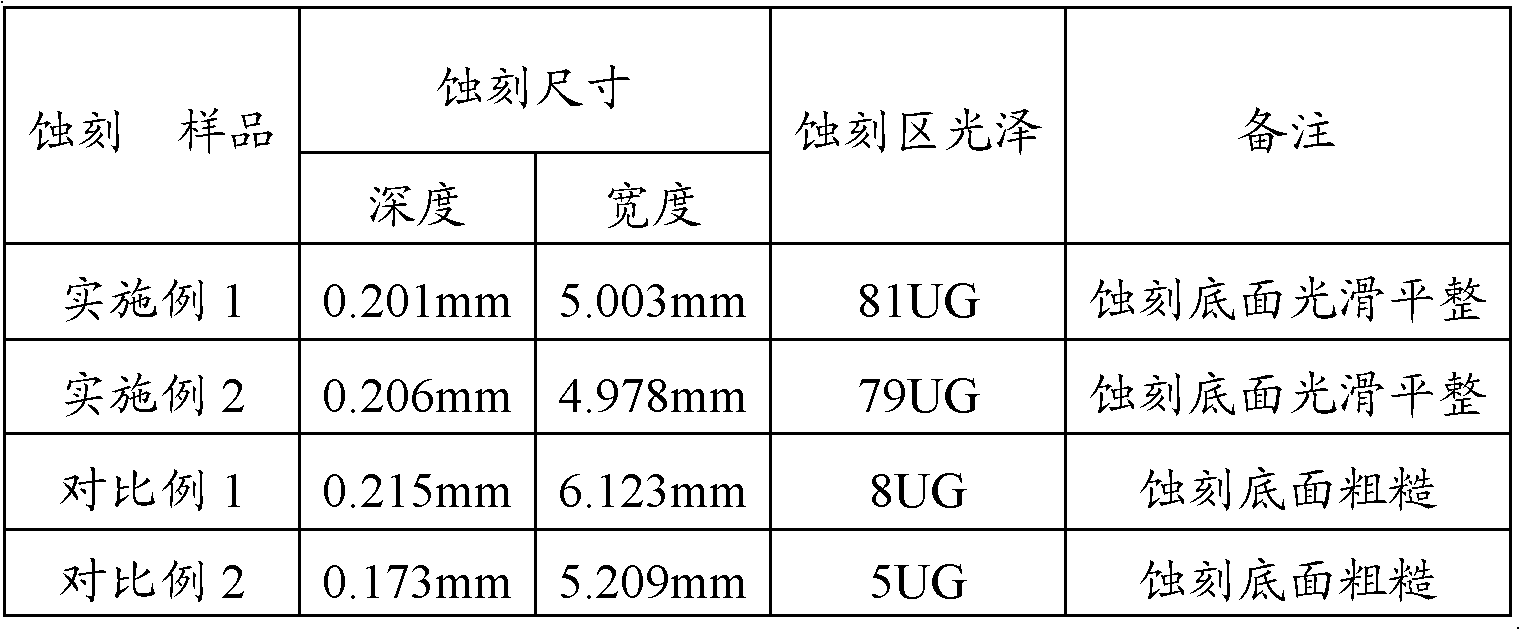

Electroetching solution used for electroetching of amorphous alloy member and etching method

The invention discloses an electroetching solution used for electroetching of an amorphous alloy member and an etching method. The electroetching solution contains 5 to 15 wt% of a polishing agent, 5 to 15 wt% of an etchant and 0.7 to 7 wt% of a corrosion inhibitor. The etching method comprises the following steps: arranging a mask on the surface of the amorphous alloy member; carrying out chemical etching on the amorphous alloy member provided with the mask on its surface by using a chemical etching solution; carrying out electroetching on the amorphous alloy member having undergone chemical etching by using the electroetching solution; and removing the mask on the surface of the amorphous alloy member after electroetching so as to obtain the amorphous alloy member with an etched pattern. With the etching method for the amorphous alloy member in the invention, etching precision and dimension can be effectively controlled, an etched region is allowed to have smooth shading and high glossiness, and surface decorative performance of the amorphous alloy member is improved.

Owner:BYD CO LTD

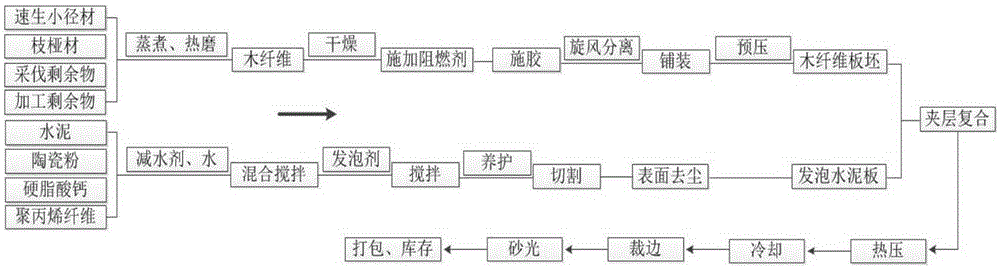

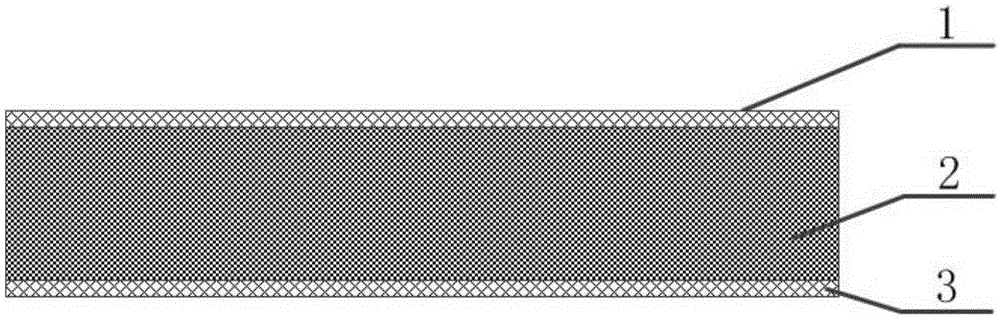

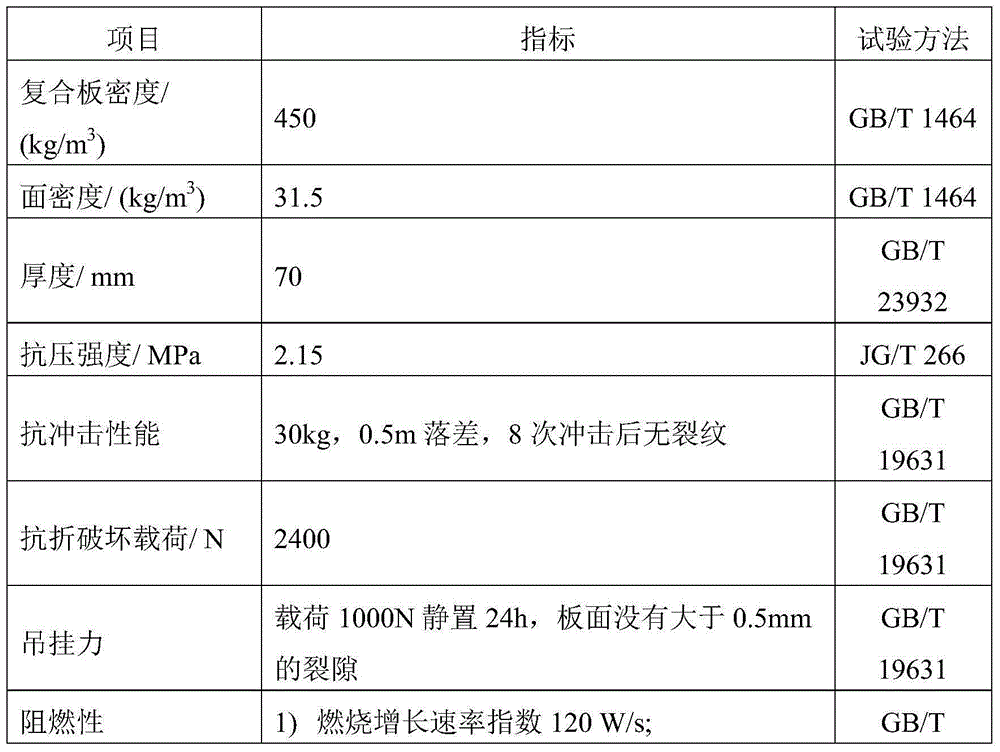

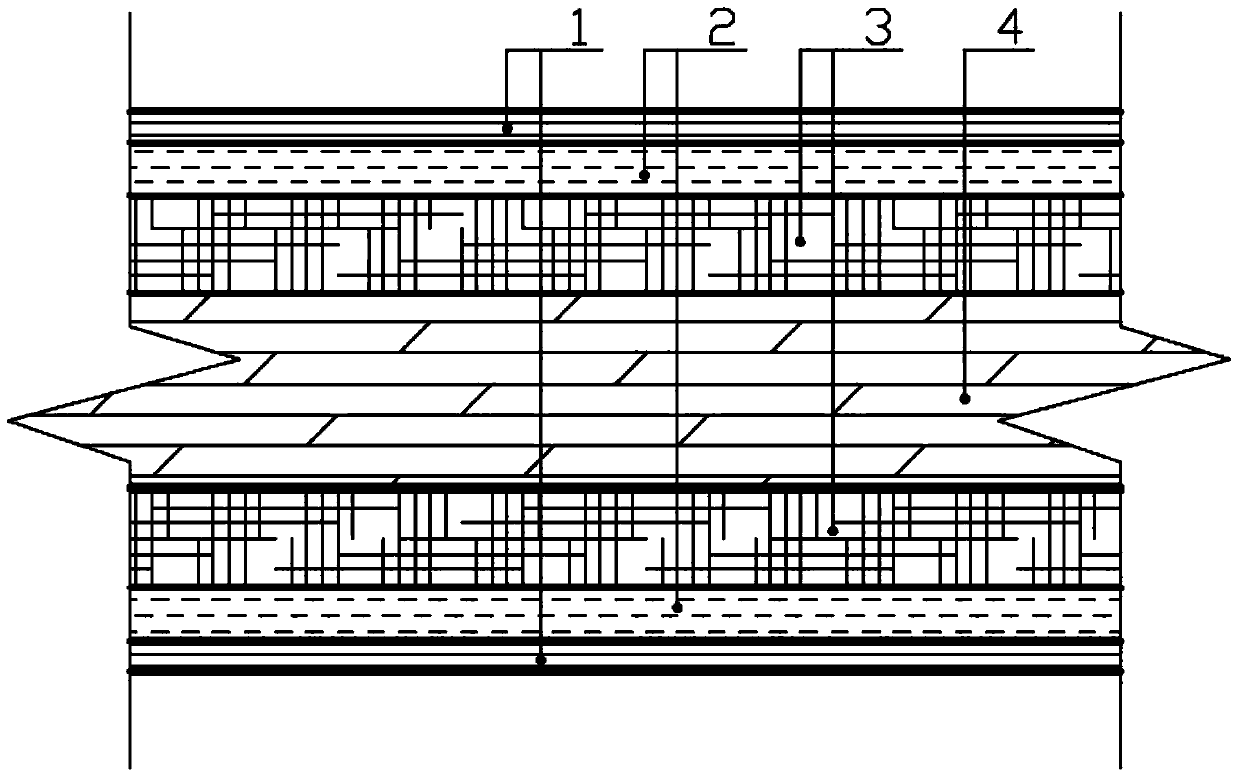

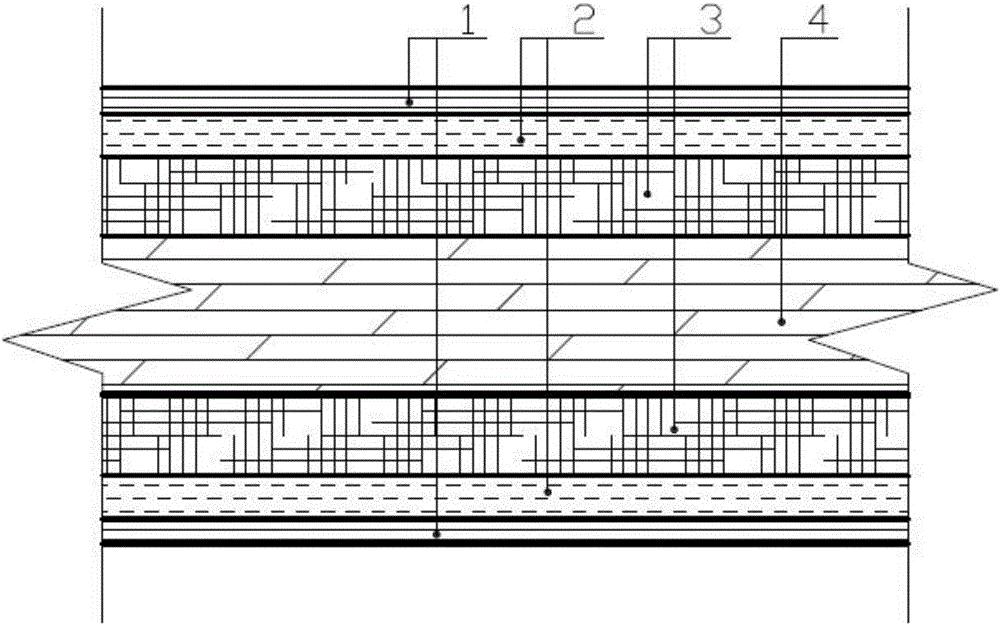

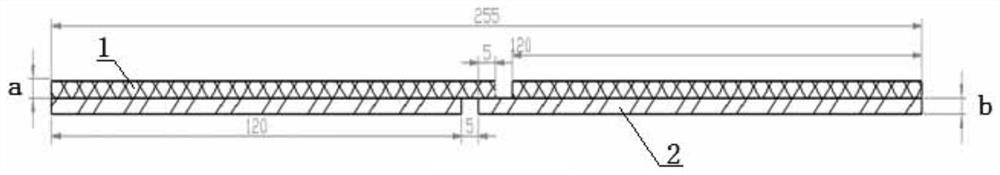

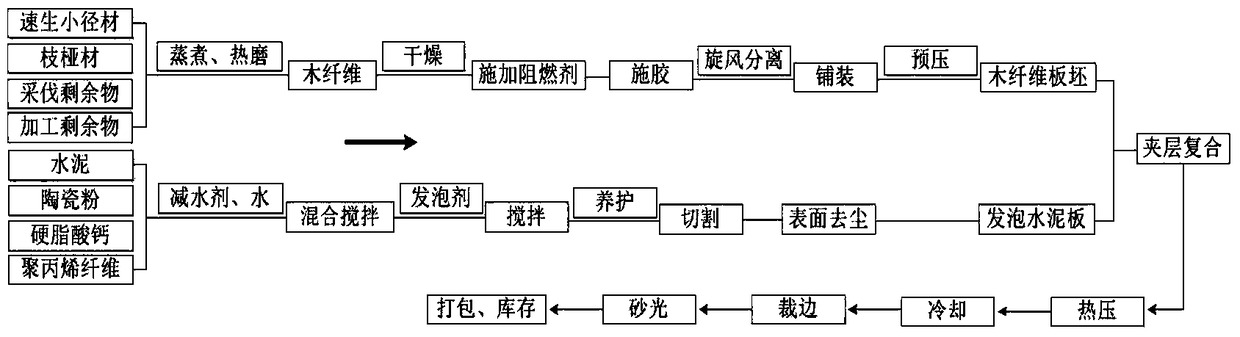

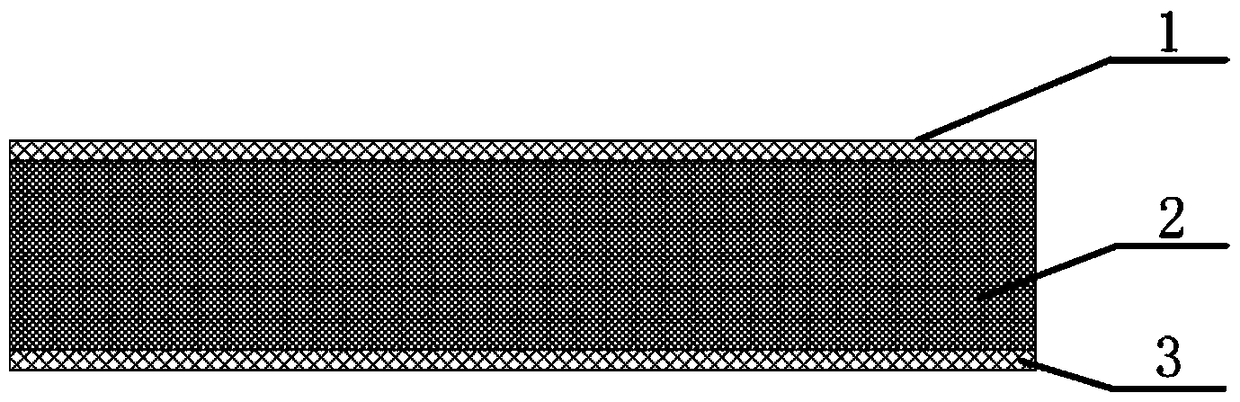

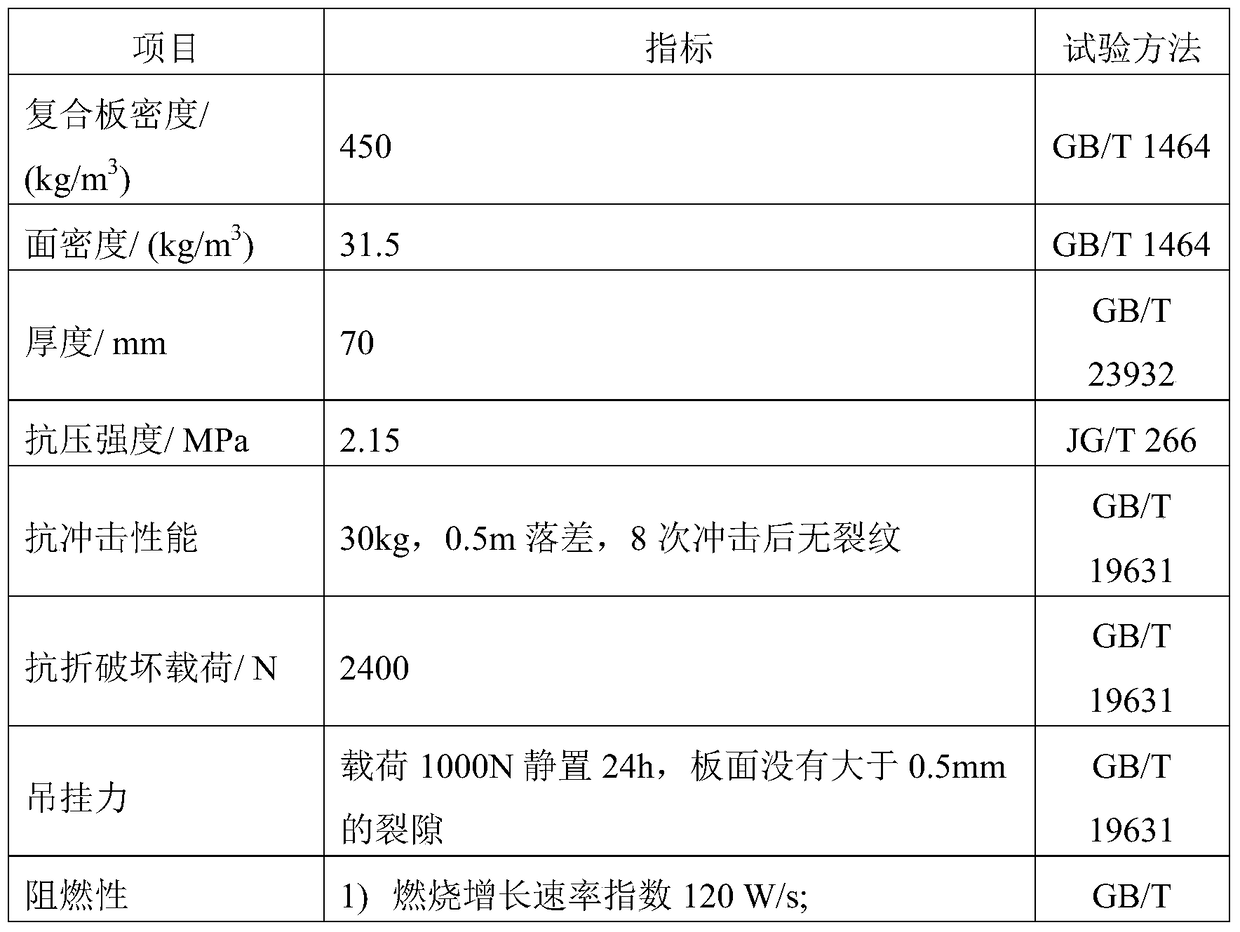

Composite board and preparation method thereof

ActiveCN105201085AHigh strengthHigh tensile strengthLaminationLamination apparatusSocial benefitsSurface layer

The invention relates to a composite board which comprises a wood fiber surface layer and a foaming cement sandwich layer. Preferably, the wood fiber surface layer comprises a wood fiber, a flame retardant and an adhesive. The invention also provides a preparation method of the composite board, which comprises the following steps: preparing a foaming cement board; providing the wood fiber; applying the adhesive on the wood fiber; applying the flame retardant on the wood fiber on which the adhesive is applied; paving the wood fiber obtained in the step D for forming, and pre-pressing to obtain formed slabs; and putting the foaming cement board between the two formed slabs, pre-pressing, and then molding by hot pressing. The composite board provided by the invention has improved overall mechanical properties and enhanced surface decoration property, can be applied to the fields of thermal insulation of industrial and civil building walls, internal decorative sheets of buildings, internal partition walls of offices, fireproof wallboards, sound insulation and noise reduction and the like, and has relatively good economical and social benefits.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

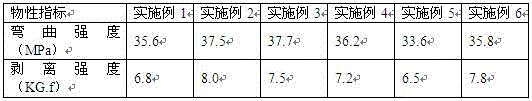

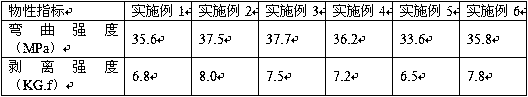

Polypropylene edge banding and preparation method

The invention belongs to the technical field of edge banding, and in particular relates to polypropylene edge banding and a preparation method. The polypropylene edge banding comprises the following raw materials in parts by weight: 80-120 parts of polypropylene, 5-25 parts of polyamide 6, 2-10 parts of a polyolefin graft, 5-25 parts of nano calcium carbonate, 0.2-1 part of an outer lubricant, 0.2-0.6 part of ultraviolent absorbant and 0.2-0.6 part of an antioxidant. The peeling strength with a plate, of the polypropylene edge banding provided by the invention, is increased to be 6.5 Kgf or above from an average value of 4.5 Kgf of an identical product of the prior art, that is, the peeling strength with the plate is increased by 40% or above.

Owner:SINOWOLF PLASTIC DEKOR

Woodiness function gradient laminate for high size-stability structure and manufacturing method of woodiness function gradient laminate for high size-stability structure

InactiveCN103802175AHigh strengthHigh gel contentWood veneer joiningWood layered productsSurface layerSingle plate

The invention discloses a woodiness function gradient laminate for a high size-stability structure and a manufacturing method of the woodiness function gradient laminate for the high size-stability structure. The woodiness function gradient laminate is characterized in that fast-growing woodiness recombination units serve as core layers, high-strength woodiness recombination units or bamboo recombination units serve as outer layers, inorganic solutions soaked by the units on the adjacent layers are in contact and are hot-pressed to produce gel, and the woodiness function gradient laminate is formed. The woodiness function gradient laminate has the advantages that use materials are structural woods or low-quality man-made forest small-diameter grade woods or branch woods or leftover materials or bamboo woods, the product structure is reasonable and designable, the material use rate is high, the product cost is low, the mechanical strength is high, the size stability is high, the service life is long, the product is anticorrosion and capable of preventing insects, and has the functionality such as inflaming retarding, and the woodiness function gradient laminate can be used as building wall materials, a floorboard or a roof board; the surfaces of the materials are covered with a whole chemical woodiness single plate to serve as the surface layer and the secondary surface layer, the attractive appearance decoration effect can be achieved, and the woodiness function gradient laminate can be completely used for replacing traditional woodiness laminate materials such as a plywood and laminated veneer lumber and can be used as furniture and home decoration materials.

Owner:NANJING UNIV OF TECH

Method and process of steel structure arc spraying composite corrosion proof coating system

ActiveCN101451243BUndamagedDecorativeLiquid surface applicatorsMolten spray coatingCoating systemChemical products

The invention provides a method and a process for spraying a composite anticorrosive coating system by electric arc for a steel structure, which belong to the method and the process for anticorrosion of the steel structure. In the anticorrosive coating system, first, rust removal and coarsing are carried out on the surface of the steel structure; then, an anode metal coating is sprayed by electric arc; then, a nanometer modified epoxy seal paint as a primer coating, an MIO epoxy paint or nanometer modified MIO epoxy paint as an intermediate paint coating, and a nanometer modified fluorine-containing polyurethane paint or fluorine-containing polysiloxane paint or siloxane modified acrylic polyurethane as a finishing coating are coated on the metal coating in sequence. The composite anticorrosive coating system has excellent performances of corrosion resistance, weather resistance, stain resistance, chemical product resistance, decoration and the like, and can obviously reduce or remit anticorrosive maintenance work and cost of the steel structure in late stage.

Owner:JIANGSU CUMT DAZHENG SURFACE ENG TECH

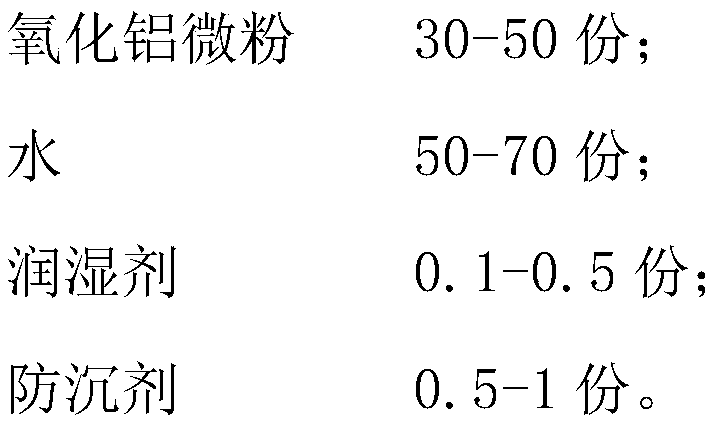

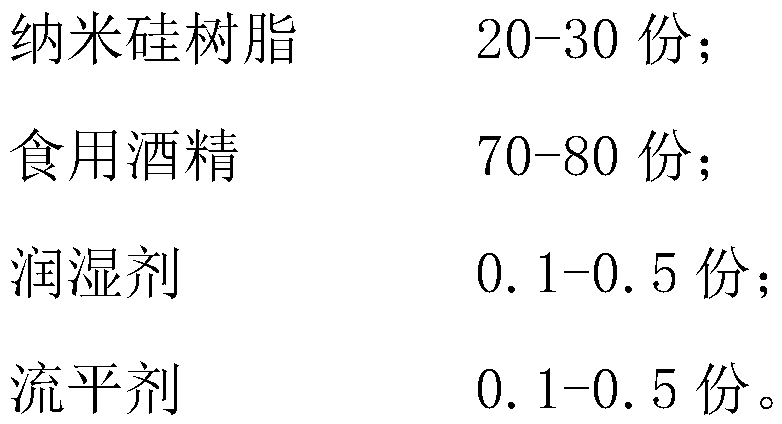

Ceramic composite material for thermal spraying on metal surface and preparation and application method thereof

A ceramic composite material for thermal spraying on metal surface comprises the following components in percentages by weight: 50%-60% of TiO2, 20%-30% of Al2O3, 5%-8% of ZrO2, 0.5%-1.0% of Y2O3, 0.8%-1.0% of Cr2B, 8%-10% of Ni, and 0.8%-1.0% of Mo. A preparation method of the ceramic composite material for thermal spraying on metal surface comprises the following steps of: 1) preparing a ceramic component material; 2) using the ceramic component material to prepare a ceramic slurry that contains composite powder through high-energy ball milling; 3) performing dispersing and ball milling on the composite powder; and 4) evaporating water in the ceramic slurry through ball milling to prepare dry ceramic composite powder. In addition, the ceramic composite material is coated on the metal surface through a thermal spraying method, and thereby forming a dense ceramic coating on the metal surface. The ceramic composite material is applied on products such as mobile phone shells, so that the aesthetic property of the product can be improved while the surface strength of the product is improved.

Owner:GUANGDONG JANUS SMART GRP CO LTD +1

Coating technology

InactiveCN110778041AWill not affect workDoes not affect activityCovering/liningsGlazeUltraviolet lights

The invention discloses a coating technology used for surface water preventing and renovating of surfaces of glazed tiles and other building materials. The coating technology comprises the following steps that firstly, the surface of a raw building material is cleaned and ground, and the surface roughness is increased; secondly, coating of an interface agent is conducted; thirdly, coating of waterproof primer is conducted; fourthly, coating of a non-solvent ultraviolet light curing finishing coat is conducted, ultraviolet light irradiation curing is conducted, and a new surface is obtained; and the building material is glazed tiles, stone, glass, metal or wood products. The coating technology has the characteristics of being waterproof, firm in bonding, good in decoration effect, free of noise in the construction process, high in renovating speed and the like; and good adhesive force is achieved for tile glaze faces / polished faces, technology patterns can be customized, the surface decoration effect is further improved, and the personalized new decorating effect is achieved.

Owner:广东立盈新材料有限公司

Magnesium-aluminum alloy composite material and preparation process thereof

ActiveCN113263052AReduce lossIncrease strength bond strengthFurnace typesWork heating devicesLiquid stateAlloy composite

The invention discloses a magnesium-aluminum alloy composite material and a preparation process thereof. The preparation process comprises the following steps that S1, materials are prepared, specifically, the surfaces of a prepared composite magnesium alloy plate, an aluminum alloy plate and auxiliary materials are cleaned, and it is guaranteed that the surfaces of the materials are free of oxide, oil dirt and impurities; S2, the materials subjected to surface treatment are stacked, auxiliary materials are located between the magnesium alloy plate and the aluminum alloy plate, and simple composite fixing is conducted; S3, the materials are put into a furnace to be preheated to melt the auxiliary materials, and then multiple times of hot rolling compounding are conducted till the materials reach a target thickness; and S4, after rolling is completed, thermal diffusion annealing treatment is conducted. After the auxiliary materials with a lower melting point is preheated and melted, the auxiliary materials are uniformly laid on the surface of the magnesium alloy plate in a liquid state to protect the composite surface of the magnesium alloy plate from being oxidized, and the liquid auxiliary materials are extruded out after the plate enters a roller during rolling, so that the hot rolling composite forming of the non-oxidized magnesium plate and aluminum plate is ensured.

Owner:CHANGSHA ADVANCED MATERIALS IND RES INST CO LTD

Method for sheathing thermal shrink film label to cone cup

The invention relates to a method for sheathing a thermal shrink film label to a cone cup, which comprises the following steps of: printing image and text information; printing hot melt glue; manufacturing a thermal shrink film label; sheathing the thermal shrink film label; and heating the cone cup to adhere the thermal shrink film label in three stages of steam heating, wherein a steam vent at the rim of the cone cup is heated for 8-12 s at the temperature of 80-90 DEG C in the first stage of steam heating, the steam vent at the middle cup body of the cone cup is heated for 8-12 s at the temperature 70-80 DEG C and the steam vent at the bottom cup body of the cone cup is heated for 8-12 s at the temperature of 70-80 DEG C. By using the method, the thermal shrink film label is smoothly and tightly attached to the surface of the cone cup and can be fixed to the largest diameter position of the rim of the cone cup, and the thermal shrink film label can not slip off the surface of the cone cup and is especially applicable to the Styrofoam cone cup with smooth surface; by printing the image and text information on the thermal shrink film, the image and text information can be prevented from wearing, but also the surface decoration effect of the cone cup is increased.

Owner:ZHENGXIN PACKAGING CO LTD DONGGUAN

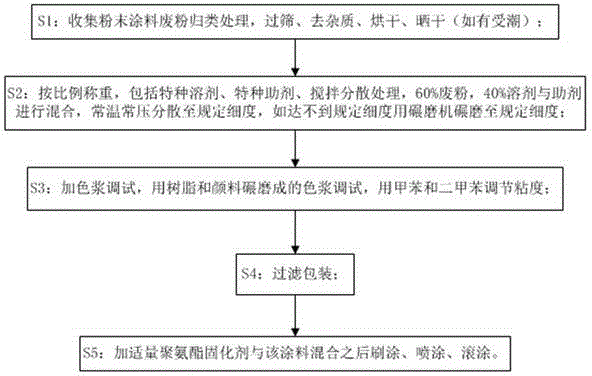

Method for recycling and processing waste powder of powder coating into solvent type coating

InactiveCN104693982AImprove anti-corrosion performanceImprove the surface decoration effectAnti-corrosive paintsPolyurea/polyurethane coatingsXylyleneFirming agent

The invention discloses a method for recycling and processing waste powder of a powder coating into a solvent type coating. The method is characterized by comprising the following steps: collecting the waste powder of the powder coating and classifying; screening, removing the impurities, drying and airing (if the waste powder is affected by dampness); weighing special solvents and special additives according to the proportion, and stirring and dispersing; mixing 60 percent of waste powder and 40 percent of solvents with the additives, dispersing to reach a specified fineness under constant temperature and constant pressure, and grinding to reach the regular fineness by using a grinding machine if the specified fineness does not reach; adding color paste to regulate; regulating by using color paste formed by grinding resins and pigments and regulating the velocity by using methylbenzene and xylene; filtering and packing; adding a proper amount of polyurethane curing agent and mixing with the coating; brush-coating, spray-coating and rolling-coating. According to the method, the outdoor and indoor waste powder is renewedly processed into the solvent type coating through special materials, solvents and techniques; because the raw material contains epoxy resins, polyester resins and the like with high performance, the prepared coating is extremely-high in corrosion resistant performance and relatively high in surface decoration performance; moreover, the cost is only half of an ordinary similar series product, so that the cost is greatly reduced.

Owner:CHANGZHOU ZHIYOU PAINT CO LTD

Preparation method of heat-resistant powdery coating

InactiveCN105017925AUniform particle sizeGood compatibilityInorganic pigment treatmentPowdery paintsEpoxyCompatibilization

The invention discloses a preparation method of a heat-resistant powdery coating. The preparation method utilizes a two-step crushing method to prepare the heat-resistant powdery coating with uniform particle sizes, improves formula component compatibility, solves the problem of appearance defects such as pin holes and bubbles produced in curing of the conventional epoxy resin powdery coating and greatly improves surface decoration effects and high temperature resistance of a coated product.

Owner:ANHUI HUAHUI SUYE TECH SHARE CO LTD

Machining method for improving corrosion resistance of stainless steel

The invention belongs to the technical field of stainless steel plates and particularly relates to a machining method for improving corrosion resistance of stainless steel. The machining method comprises the steps of oil removal, cleaning for the first time, acid cleaning activation, cleaning for the second time, neutralizing treatment, cleaning for the third time, drying and packaging in a sealed mode. Compared with the prior art, the machining method has the following advantages that through the oil removal mode, the oil removal effect is good, operation is convenient and fast, and the machining time is shortened; a stainless steel substrate subjected to freezing treatment is activated after being passivated with an acid solution, the effect that the reaction is stable and complete can be ensured, and the corrosion resistance and antifouling performance of the stainless steel are improved; as cleaning is conducted with a cleaning solution, the operation method is simple, the surface decorativeness of stainless steel products can be improved, and pollution to the environment is low; and the stainless steel plates machined through the method are high in corrosion resistance, good in surface decorativeness and suitable for being popularized.

Owner:安徽伟凯型材有限公司

Components for decorating inside wall surface

The invention relates to a component for decorating interior walls, which includes a decorative plate made of a thin plate made of high-density flame-retardant foamed polystyrene material and double-sided adhesive, and a button cover, a button seat and a double-sided adhesive. It is an adhesive-type decorative buckle composed of glue, which has the functions of limiting and embellishing and beautifying the overall decorative surface. The buckle cover is in the shape of a cup with a bottom. The limit cover plate is formed, and the buckle seat is cup-shaped with a bottom, which is composed of a cup body with a limit groove on the inner side and a buckle bottom fixed with double-sided adhesive tape on the bottom surface. When in use, the decorative plate and the buckle seat are set on the clean and flat foundation wall through double-sided adhesive tape as needed, and the buckle cover is assembled and set on the buckle seat through the limit protrusion and the limit groove. It plays the role of clamping and limiting. Because the components are thin and light, they can be pasted reliably with double-sided tape without falling off. The setting cost is low and convenient, saving time and effort. After setting, it can bring energy saving, environmental protection, safety and beauty. Technical effect, with strong practicality.

Owner:周文齐

Wooden functionally graded laminate for high dimensional stability structure and preparation method thereof

InactiveCN103802175BHigh strengthHigh gel contentWood veneer joiningWood layered productsSurface layerSingle plate

The invention discloses a woodiness function gradient laminate for a high size-stability structure and a manufacturing method of the woodiness function gradient laminate for the high size-stability structure. The woodiness function gradient laminate is characterized in that fast-growing woodiness recombination units serve as core layers, high-strength woodiness recombination units or bamboo recombination units serve as outer layers, inorganic solutions soaked by the units on the adjacent layers are in contact and are hot-pressed to produce gel, and the woodiness function gradient laminate is formed. The woodiness function gradient laminate has the advantages that use materials are structural woods or low-quality man-made forest small-diameter grade woods or branch woods or leftover materials or bamboo woods, the product structure is reasonable and designable, the material use rate is high, the product cost is low, the mechanical strength is high, the size stability is high, the service life is long, the product is anticorrosion and capable of preventing insects, and has the functionality such as inflaming retarding, and the woodiness function gradient laminate can be used as building wall materials, a floorboard or a roof board; the surfaces of the materials are covered with a whole chemical woodiness single plate to serve as the surface layer and the secondary surface layer, the attractive appearance decoration effect can be achieved, and the woodiness function gradient laminate can be completely used for replacing traditional woodiness laminate materials such as a plywood and laminated veneer lumber and can be used as furniture and home decoration materials.

Owner:NANJING TECH UNIV

Magnesium/aluminum alloy composite material and preparation process thereof

ActiveCN113275380AHigh bonding strengthReduce porosityMolten spray coatingAuxillary arrangementsAlloy compositeAluminium alloy

The invention discloses a magnesium / aluminum alloy composite material and a preparation process thereof. The preparation process comprises the following steps: S1, preparing materials, specifically, spraying the surface, to be compounded, of a magnesium alloy plate, and performing surface treatment on the surface, to be compounded, of an aluminum alloy plate so as to ensure that the surface is free of oxides, oil stains and impurities; S2, after the surfaces, to be compounded, of the magnesium alloy plate and the aluminum alloy plate are adhered, performing simple compounding and fixing on the whole body; S3, preheating the whole body in a furnace, and performing multi-pass hot rolling so as to obtain a composite material with a target thickness; and S4, performing thermal diffusion annealing treatment on the rolled plate. The surface of a magnesium alloy is treated by plasma spraying, an oxidation layer on the surface of the magnesium alloy is directly removed under the spraying action, and the process for removing the oxidation layer on the surface of the magnesium alloy is optimized; an aluminum melt at a high temperature is splashed to the magnesium alloy plate at a high speed and is fused with a part of the magnesium alloy plate so as to achieve metallurgical bonding, and strong bonding is formed under the permeation action at a high temperature.

Owner:航天科工(长沙)新材料研究院有限公司

Composition of surface chemistry plating liquid and preparation method for wooden electromagnetic screen material

InactiveCN101148757BProtect health and safetyImprove the surface decoration effectLiquid/solution decomposition chemical coatingChemical platingPhysical chemistry

The present invention provides one kind of chemical plating liquid composition for wooden material and the process of preparing electromagnetic shielding material on the surface of wooden material. The chemical plating liquid composition consists of metal salt 2.0-7.0 weight portions and complexing agent 3.0-6.0 weight portions. The chemical plating process includes the steps of water boiling of wooden material, surface treating, surface sensitizing and activating, reducing and surface chemical plating. The obtained electromagnetic shielding material has an electromagnetic shielding effectiveness in the frequency range of 5 KHz-1500 MHz up to 31.8dB-51.4dB. The present invention can raise the surface decoration effect of wooden material, endows wooden material with conducting performance and electronic shielding performance, raise the application value and use safety of wooden material.

Owner:BEIJING FORESTRY UNIVERSITY

A kind of composite board and preparation method thereof

ActiveCN105201085BHigh compressive strengthHas woody natural propertiesLaminationLamination apparatusSocial benefitsSurface layer

The invention relates to a composite board which comprises a wood fiber surface layer and a foaming cement sandwich layer. Preferably, the wood fiber surface layer comprises a wood fiber, a flame retardant and an adhesive. The invention also provides a preparation method of the composite board, which comprises the following steps: preparing a foaming cement board; providing the wood fiber; applying the adhesive on the wood fiber; applying the flame retardant on the wood fiber on which the adhesive is applied; paving the wood fiber obtained in the step D for forming, and pre-pressing to obtain formed slabs; and putting the foaming cement board between the two formed slabs, pre-pressing, and then molding by hot pressing. The composite board provided by the invention has improved overall mechanical properties and enhanced surface decoration property, can be applied to the fields of thermal insulation of industrial and civil building walls, internal decorative sheets of buildings, internal partition walls of offices, fireproof wallboards, sound insulation and noise reduction and the like, and has relatively good economical and social benefits.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

A kind of polypropylene edge banding and preparation method

The invention belongs to the technical field of edge banding, and in particular relates to polypropylene edge banding and a preparation method. The polypropylene edge banding comprises the following raw materials in parts by weight: 80-120 parts of polypropylene, 5-25 parts of polyamide 6, 2-10 parts of a polyolefin graft, 5-25 parts of nano calcium carbonate, 0.2-1 part of an outer lubricant, 0.2-0.6 part of ultraviolent absorbant and 0.2-0.6 part of an antioxidant. The peeling strength with a plate, of the polypropylene edge banding provided by the invention, is increased to be 6.5 Kgf or above from an average value of 4.5 Kgf of an identical product of the prior art, that is, the peeling strength with the plate is increased by 40% or above.

Owner:SINOWOLF PLASTIC DEKOR

Method for sheathing thermal shrink film label to cone cup

The invention relates to a method for sheathing a thermal shrink film label to a cone cup, which comprises the following steps of: printing image and text information; printing hot melt glue; manufacturing a thermal shrink film label; sheathing the thermal shrink film label; and heating the cone cup to adhere the thermal shrink film label in three stages of steam heating, wherein a steam vent at the rim of the cone cup is heated for 8-12 s at the temperature of 80-90 DEG C in the first stage of steam heating, the steam vent at the middle cup body of the cone cup is heated for 8-12 s at the temperature 70-80 DEG C and the steam vent at the bottom cup body of the cone cup is heated for 8-12 s at the temperature of 70-80 DEG C. By using the method, the thermal shrink film label is smoothly and tightly attached to the surface of the cone cup and can be fixed to the largest diameter position of the rim of the cone cup, and the thermal shrink film label can not slip off the surface of the cone cup and is especially applicable to the Styrofoam cone cup with smooth surface; by printing the image and text information on the thermal shrink film, the image and text information can be prevented from wearing, but also the surface decoration effect of the cone cup is increased.

Owner:ZHENGXIN PACKAGING CO LTD DONGGUAN

Composition for chemical Cu plating onto timber surface and the chemical Cu plating process

InactiveCN100451168CImprove the surface decoration effectLiquid/solution decomposition chemical coatingCopper coatingCopper plating

The present invention discloses one kind of composition for chemical copper plating onto timber surface and the chemical copper plating process. The composition contains copper compound, complexing agent and reductant. The chemical copper plating process is to set the timber in the composition solution, so that copper ion is reduced through chemical reaction and deposited homogeneously onto the surface of the timber and the timber surface possesses metal decoration effect and conducting performance. The present invention can reach copper coating thickness over 3.5 microns and square resistivity as low as 0.06 ohm, being comparable with copper foil.

Owner:BEIJING FORESTRY UNIVERSITY

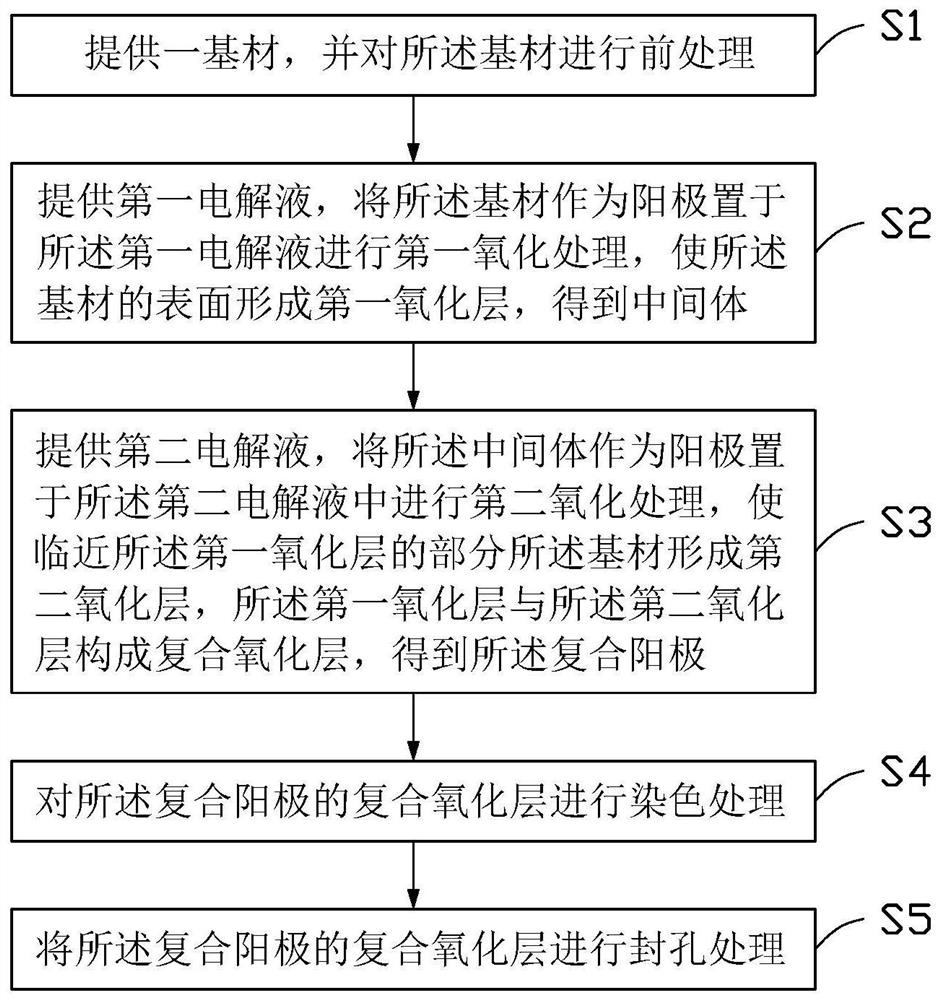

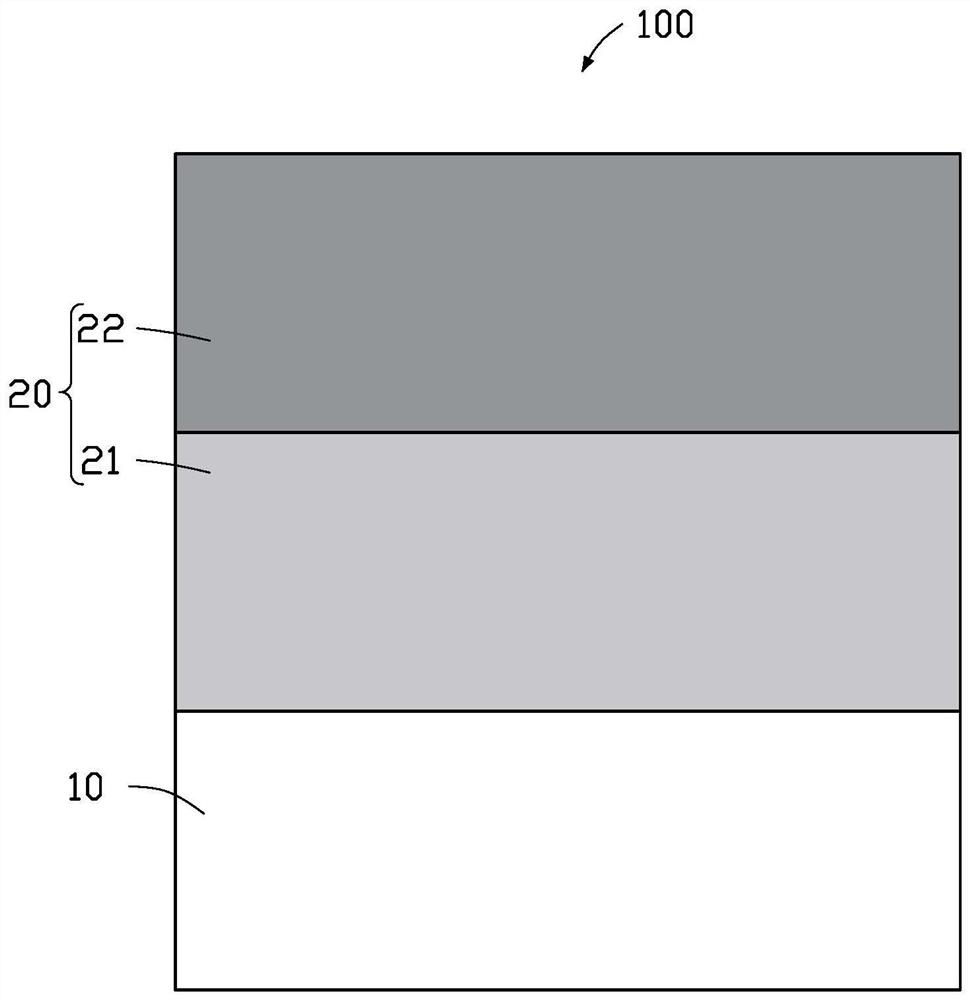

Preparation method of composite anode and composite anode

PendingCN114481250AHigh hardnessImprove wear resistanceAnodisationElectrolytic agentPhysical chemistry

The preparation method of the composite anode comprises the steps that a base material is placed in a first electrolyte to be subjected to first oxidation treatment, a first oxidation layer is formed on the surface of the base material, an intermediate is obtained, and the first oxidation treatment conditions are that the oxidation temperature is-2 DEG C to 2 DEG C, the oxidation voltage is 27 V to 40 V, the oxidation time is 14 min to 20 min, the current density is 1 A / dm < 2 > to 5 A / dm < 2 >, and the current climbing time is 1 min to 3 min; and the intermediate is placed in a second electrolyte to be subjected to second oxidation treatment, the part, close to the first oxidation layer, of the base material forms a second oxidation layer, the first oxidation layer and the second oxidation layer form a composite oxidation layer, the composite anode is obtained, and the second oxidation treatment conditions are that the oxidation temperature ranges from 14 DEG C to 19 DEG C, the oxidation voltage ranges from 12 V to 17 V, and the oxidation time ranges from 12 min to 30 min. The composite anode prepared through the method is high in hardness, resistant to abrasion and corrosion and easy to dye.

Owner:FUZHUN PRECISION TOOLING (JIASHAN) CO LTD

A processing method for improving corrosion resistance of stainless steel

ActiveCN106757073BGood surface decorationImprove corrosion resistanceBiological activationMachining time

The invention belongs to the technical field of stainless steel plates and particularly relates to a machining method for improving corrosion resistance of stainless steel. The machining method comprises the steps of oil removal, cleaning for the first time, acid cleaning activation, cleaning for the second time, neutralizing treatment, cleaning for the third time, drying and packaging in a sealed mode. Compared with the prior art, the machining method has the following advantages that through the oil removal mode, the oil removal effect is good, operation is convenient and fast, and the machining time is shortened; a stainless steel substrate subjected to freezing treatment is activated after being passivated with an acid solution, the effect that the reaction is stable and complete can be ensured, and the corrosion resistance and antifouling performance of the stainless steel are improved; as cleaning is conducted with a cleaning solution, the operation method is simple, the surface decorativeness of stainless steel products can be improved, and pollution to the environment is low; and the stainless steel plates machined through the method are high in corrosion resistance, good in surface decorativeness and suitable for being popularized.

Owner:安徽伟凯型材有限公司

Water-based emulsion type real copper primer and preparation method thereof

The invention discloses a water-based emulsion type real copper primer, and belongs to the field of water-based paint. The water-based emulsion type real copper primer comprises the following components in percentage by mass: 5-10% of ethanol, 0.5-1% of dimethylethanolamine, 45-50% of a water-based emulsion, 0.1-0.2% of a water-based defoaming agent, 0.2-0.3% of a water-based dispersing agent, 3-5% of a water-based rheological aid, 8-10% of propylene glycol butyl ether, 0.3-0.5% of a water-based wetting agent, 1-3% of a water-based adhesion promoter, 0.1-0.3% of a water-based flattening agent, 5-10% of amino resin, 10-15% of purified water, and 8-10% of crystal pearl powder. According to the environment-friendly emulsion type real copper primer, the color retention time of the simulated copper texture effect is longer, and the surface experience feeling and satisfaction degree of customers to door products are improved.

Owner:成都市红宝丽新材料科技发展有限公司

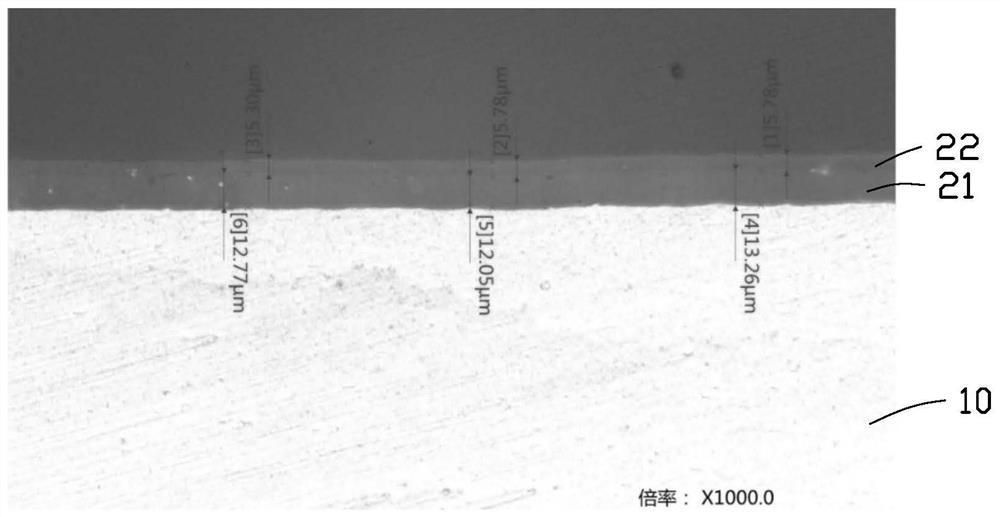

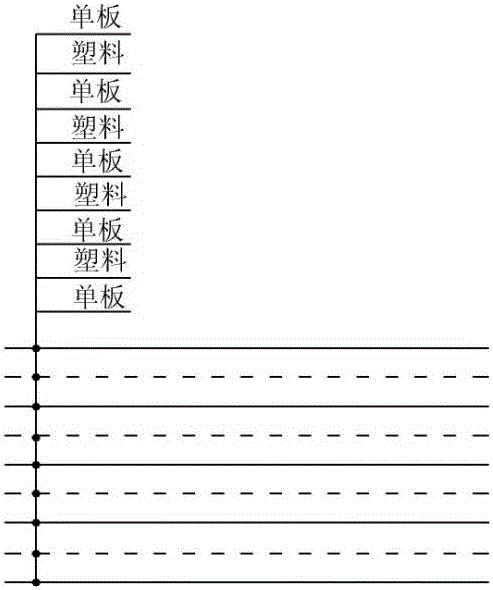

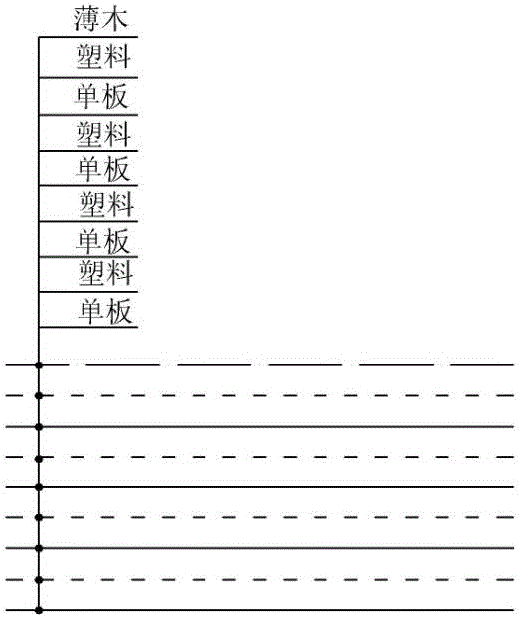

A process for wood-plastic composite manufacturing of formaldehyde-free bending and gluing parts

ActiveCN103538124BImprove bending performanceHigh bonding strengthWood veneer joiningEngineeringPlastic film

The invention relates to a new process of utilizing single-board / plastic film composite for manufacturing formaldehyde-free bending glued furniture parts. A plastic film serves as bonding material, a wooden single board serves as a basic unit, rolling hole processing is performed on a single board gluing face, tree type, thickness and specification of the single board are selected according to product usage, and a blank can be assembled, the board blank is placed in a special die to heat and press in high frequency, the board blank is bent, glued and formed, the plastic film is solidified after being cooled, and formaldehyde-free bending glued furniture parts are obtained. The process is simple and low in producing cost; the products are free of pollution and recyclable during manufacture, processing and usage, and has the advantages of environment protection, energy efficiency and efficiency, an environment friendly, safe and healthy consumption concept of the wood industry and the furniture industry can be met, and the process has extensive application value.

Owner:FUJIAN AGRI & FORESTRY UNIV

Vehicle paint and production method thereof

InactiveCN109096884AExcellent caking resistanceImprove level and brightnessFireproof paintsAnti-corrosive paintsAlcoholAcrylic resin

The invention relates to the technical field of paint, in particular to vehicle paint and a production method thereof. The vehicle paint is prepared from raw materials in parts by weight as follows: 80-120 parts of polyester resin, 50-70 parts of acrylic resin, 11-15 parts of ultrafine ceramic powder, 20-30 parts of titanium dioxide, 10-15 parts of carbon fluoroalkyl monohydric alcohol, 15-20 parts of nanometer iron oxide, 15-20 parts of nanometer titania, 20-30 parts of a curing agent, 5-15 parts of an ultraviolet screening agent, 1-4 parts of a defoaming agent, 2-3 parts of a flatting agentand 1-5 parts of a dispersing agent. The prepared vehicle paint has outstanding resistance to artificial accelerated aging, abrasion and temperature variation, is good in atomization performance, non-lifting, non-sagging and free of shrinkage cavities in a coating process and has moderate surface drying time. The vehicle paint is excellent in overall performance, has functions of retarding flame,inhibiting vibration and reducing noise, and has good weather fastness, ultraviolet screening performance and water resistance.

Owner:广西南宁维一防腐科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com