Preparation method of composite anode and composite anode

A composite anode and anode technology, applied in the direction of anodic oxidation, coating, surface reaction electrolytic coating, etc., can solve the problems of poor metal surface dyeing, unfavorable metal material decoration, poor wear resistance and corrosion resistance of oxide layer, etc. , to achieve the effect of improving surface decoration, increasing hardness and easy dyeing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

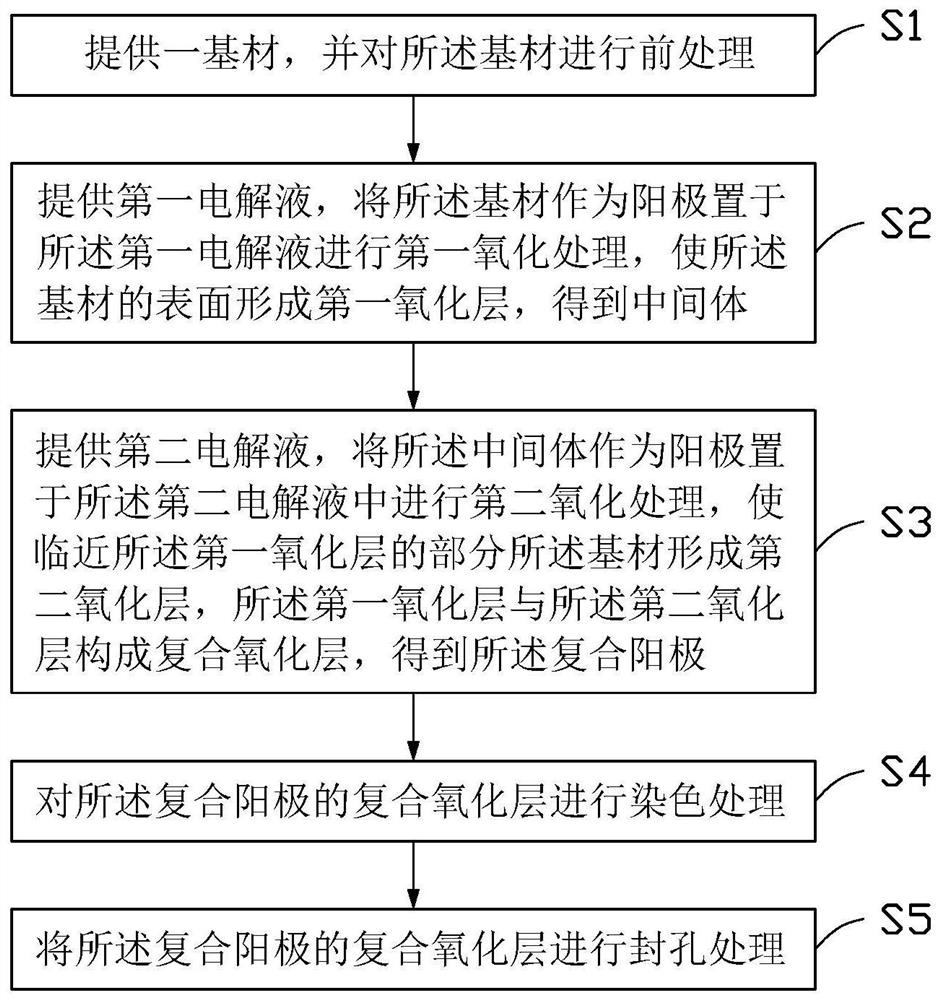

[0050] see figure 1 , combined with figure 2 and image 3 , the invention provides a method for preparing a composite anode, comprising the following steps:

[0051] Step S1, providing a substrate, and performing pretreatment on the substrate.

[0052]In this embodiment, the pretreatment includes degreasing, chemical polishing and stripping black.

[0053] In this embodiment, the base material is a metal material such as aluminum, aluminum alloy, titanium or titanium alloy, and specifically, the base material is an aluminum alloy.

[0054] Firstly, the base material is prepared into a sheet sample with a certain shape and size, specifically, the size of the sheet is 14 cm×6 cm×8 mm. The surface of the prepared sample sheet is ground and mechanically polished.

[0055] Then put the sample into 15% sulfuric acid solution for degreasing treatment, and wash the sample with water after degreasing treatment.

[0056] Put the sample after degreasing treatment into phosphoric a...

PUM

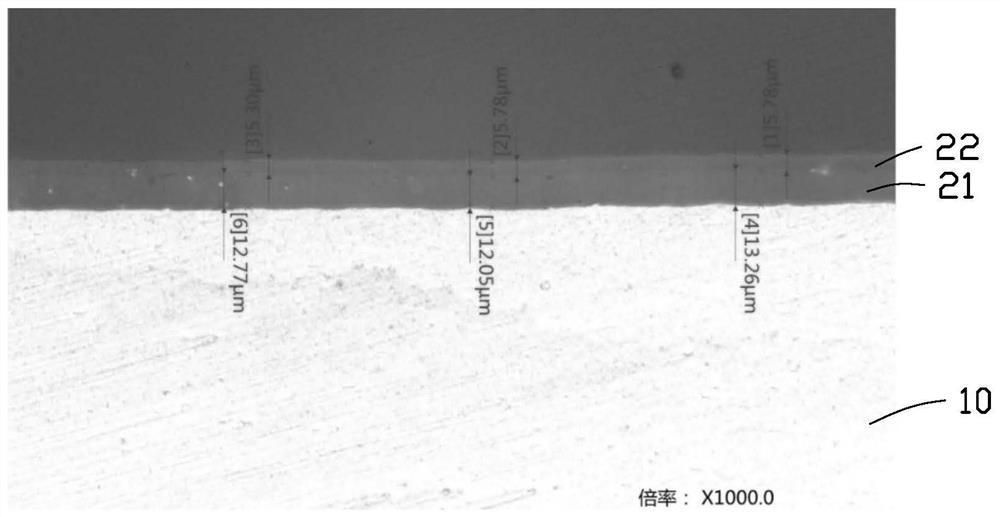

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com