Method for recycling and processing waste powder of powder coating into solvent type coating

A powder coating and solvent-based technology, applied in anti-corrosion coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of resource waste, waste powder is difficult to reuse, pollute the environment, etc., to achieve strong anti-corrosion performance, high surface Decorative performance, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

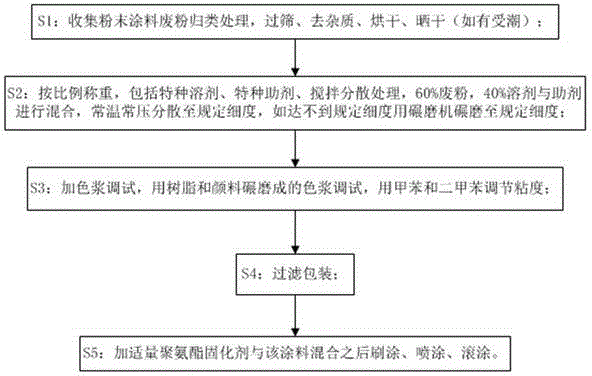

[0017] The embodiment of the present invention provides a method for reusing powder coating waste powder into solvent-based coatings. Through special materials, solvents and processes, outdoor and indoor waste powders are reprocessed into solvent-based coatings. Containing high epoxy, polyester and other resins, the coatings made have strong anti-corrosion performance and high surface decoration performance, and the cost is only half of ordinary similar series products, which greatly reduces the cost.

[0018] The method for reusing powder coating waste powder into solvent-based coatings provided by the embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0019] like figure 1 As shown, a kind of powder coating waste powder that the embodiment of the present invention provides is processed into the method for solvent-based coating again, it is characterized in that, comprises the steps:

[0020] S1: Collect powde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com