Magnesium-aluminum alloy composite material and preparation process thereof

A composite material, magnesium-aluminum alloy technology, which is applied in the field of magnesium/aluminum alloy composite material preparation, can solve the problem that it is difficult to meet the user's requirements for diversified appearance and high quality, limited types of surface treatment colors, and difficulties in the surface treatment process of magnesium alloys, etc. problems, to achieve the effect of improving composite production efficiency, easy acquisition, and improving plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

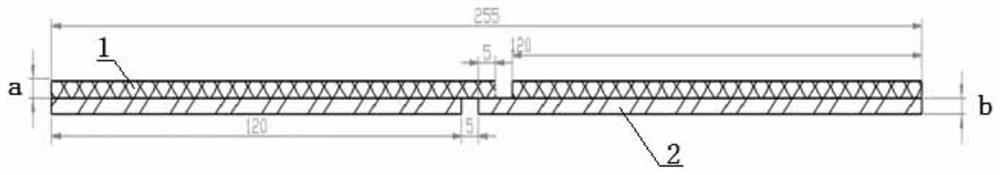

Image

Examples

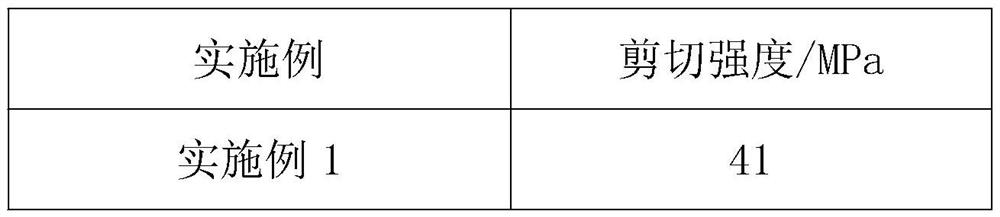

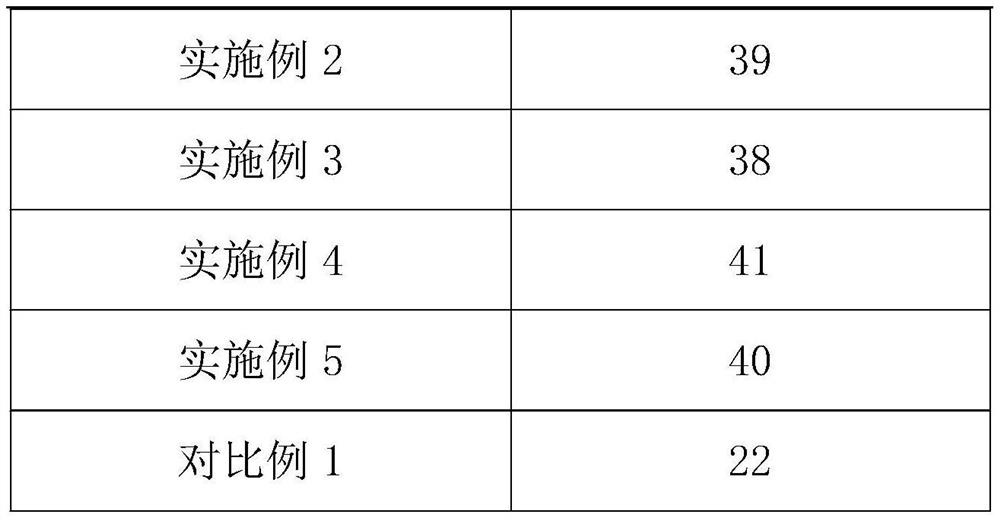

Embodiment 1

[0032] In this example, 5052 aluminum alloy and AZ31 magnesium alloy plate are selected for composite. Firstly, the prepared 2×200×300mm 5052 alloy plate, AZ31 magnesium alloy plate, and 0.5×200×300mm tin plate are subjected to surface sandblasting to remove impurities and oil stains on the surface of the plate; Aluminum alloy riveting combination; put the riveted plate horizontally into the heating furnace, and ensure that the magnesium plate is on the bottom, and keep it at 360°C for 1 hour; carry out hot rolling, the reduction is 50%, and the rolling speed is 10m / min. After the first hot-rolled plate is kept at 360°C for 10 minutes, it is hot-rolled for the second time to a thickness of about 1 mm; it is kept at 280°C for 2 hours for thermal diffusion annealing.

Embodiment 2

[0034] In this example, 6061 aluminum alloy and AZ42 magnesium alloy plate are selected for composite. Firstly, the prepared 3×200×300mm AZ42 magnesium alloy plate, 2×200×300mm 6061 alloy plate and 0.5×200×300mm tin plate are subjected to surface sandblasting to remove impurities and oil stains on the surface of the plate; The sanded plates are riveted with 6061 aluminum alloy; put the riveted plates horizontally into the heating furnace, and ensure that the magnesium plate is on the bottom, keep warm at 380°C for 1 hour; carry out hot rolling, the reduction is 60%, rolling The speed is 12m / min. After the first hot-rolled plate is kept at 380°C for 10 minutes, it is hot-rolled for the second time to a thickness of about 0.8mm; it is kept at 280°C for 2h for thermal diffusion annealing.

Embodiment 3

[0036] In this example, 6061 aluminum alloy and AZ31 magnesium alloy plate are selected for composite. First, the surface of the prepared AZ31 magnesium alloy plate of 10×200×300mm, the 6061 alloy plate of 5×200×300mm and the tin plate of 0.5×200×300mm are subjected to surface sandblasting to remove impurities and oil stains on the surface of the plate; The sanded plates are riveted with 6061 aluminum alloy; put the riveted plates horizontally into the heating furnace, and ensure that the magnesium plate is on the bottom, and keep warm at 420°C for 1 hour; carry out hot rolling, the reduction is 70%, rolling The speed is 12m / min, rolled to a thickness of about 4.5mm; thermal diffusion annealing is carried out at 280°C for 2h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com