Electroetching solution used for electroetching of amorphous alloy member and etching method

An amorphous alloy and zirconium-based amorphous alloy technology, which is applied in the field of etching solution and etching, can solve the problems of increasing the brightness of the workpiece and not having the etching effect, and achieves the improvement of surface decoration, gloss and brightness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

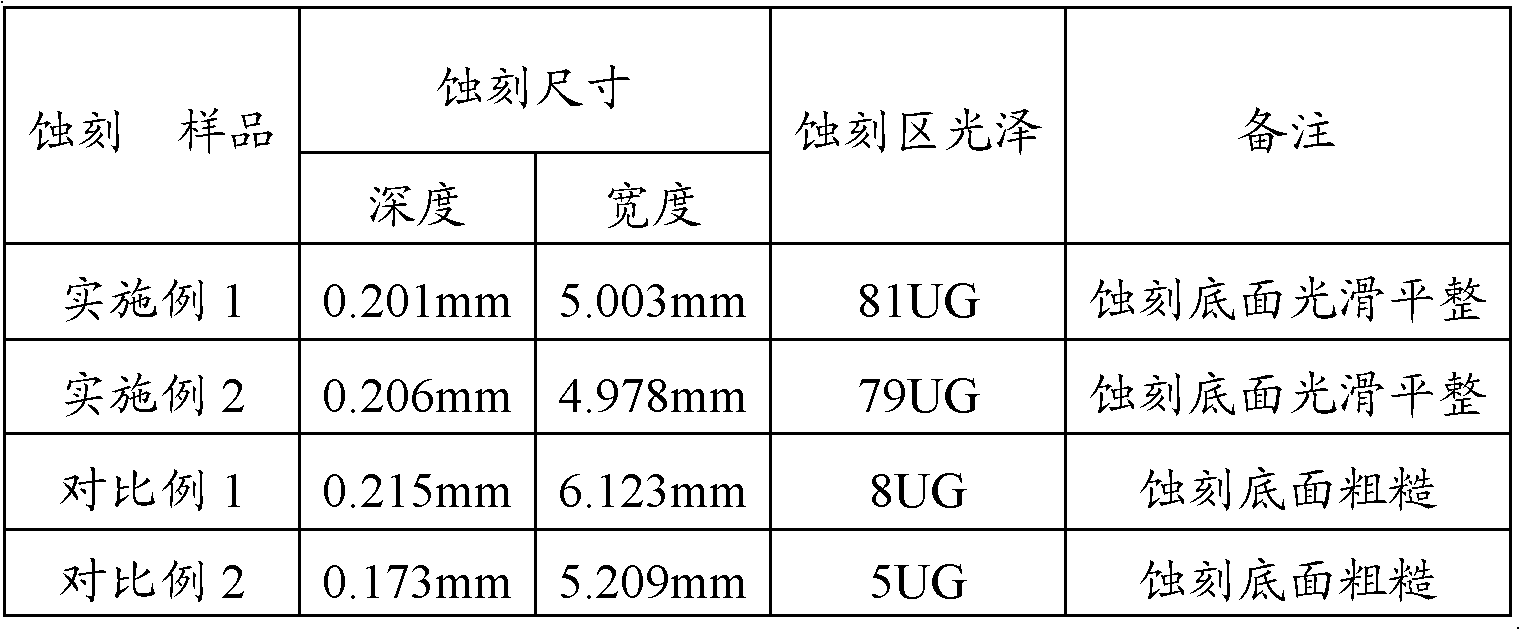

Embodiment 1

[0073] a) Set the mask

[0074] In the alkaline solution, the amorphous alloy material is used as the anode, and the stainless steel plate is used as the cathode, and the oil stain on the surface of the amorphous alloy material is removed under the action of direct current; the amorphous alloy material after degreasing is washed with water and dried , and then set a mask on the surface of the amorphous alloy material according to the pattern and pattern.

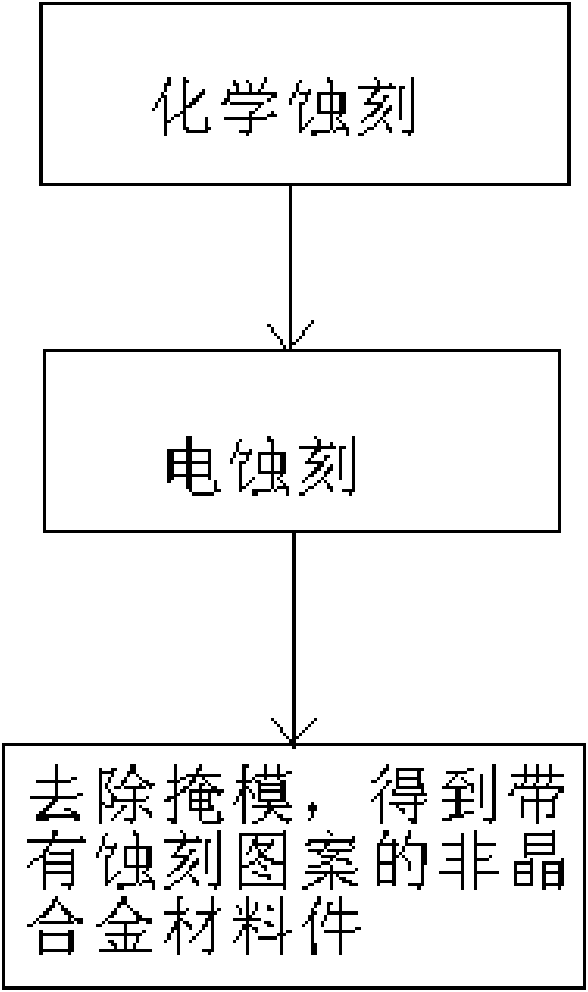

[0075] b) chemical etching

[0076] Use a solution containing 20wt% hydrochloric acid, 15wt% iron nitrate, 1wt% sodium triphosphate, and 0.5wt% benzotriazole as a chemical etching solution, and place the amorphous alloy material with a mask under the temperature condition of 25°C. Into the chemical etching solution for 5 minutes.

[0077] c) Electroetching

[0078] Using a solution containing 15wt% oleic acid, 10wt% zirconium chloride, 3wt% sodium stearate, and 1wt% sodium ethylenediamine tetramethylene phosphonate as an ...

Embodiment 2

[0082] a) Set the mask

[0083] In the alkaline solution, the amorphous alloy material is used as the anode, and the stainless steel plate is used as the cathode, and the oil stain on the surface of the amorphous alloy material is removed under the action of direct current; the amorphous alloy material after degreasing is washed with water and dried , and then set a mask on the surface of the amorphous alloy material according to the pattern and pattern.

[0084] b) chemical etching

[0085] Use a solution containing 15wt% hydrochloric acid, 20wt% ferric nitrate, 2wt% sodium triphosphate, and 1.5wt% benzotriazole as a chemical etching solution, and place the amorphous alloy material with a mask under the temperature condition of 25°C. Into the chemical etching solution for 6 minutes.

[0086] c) Electroetching

[0087] Using a solution containing 10wt% oleic acid, 15wt% zirconium chloride, 4wt% sodium laurate, and 1.5wt% sodium ethylenediamine tetramethylene phosphonate as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com