A kind of composite board and preparation method thereof

A composite board and slab technology, applied in the field of composite board and its preparation, can solve the problems of insufficient surface decoration, poor impact toughness, low strength of cement board, etc., and achieve enhanced surface decoration, increased strength, and improved overall mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

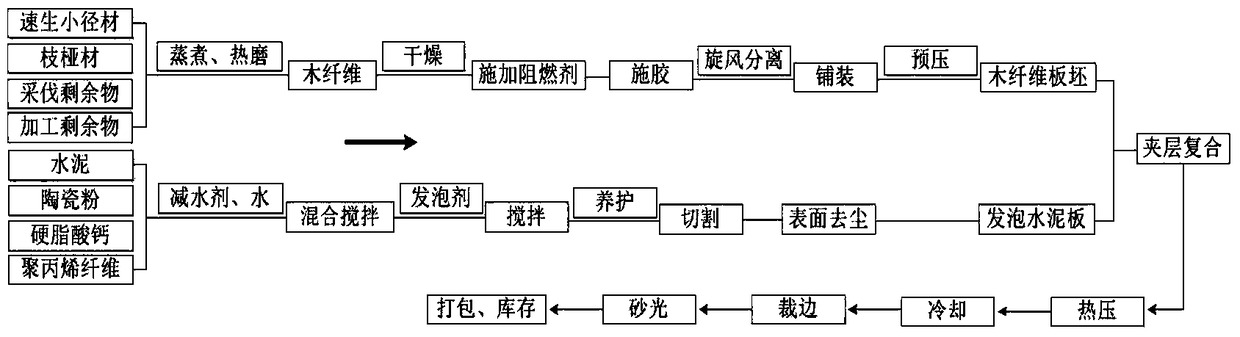

Method used

Image

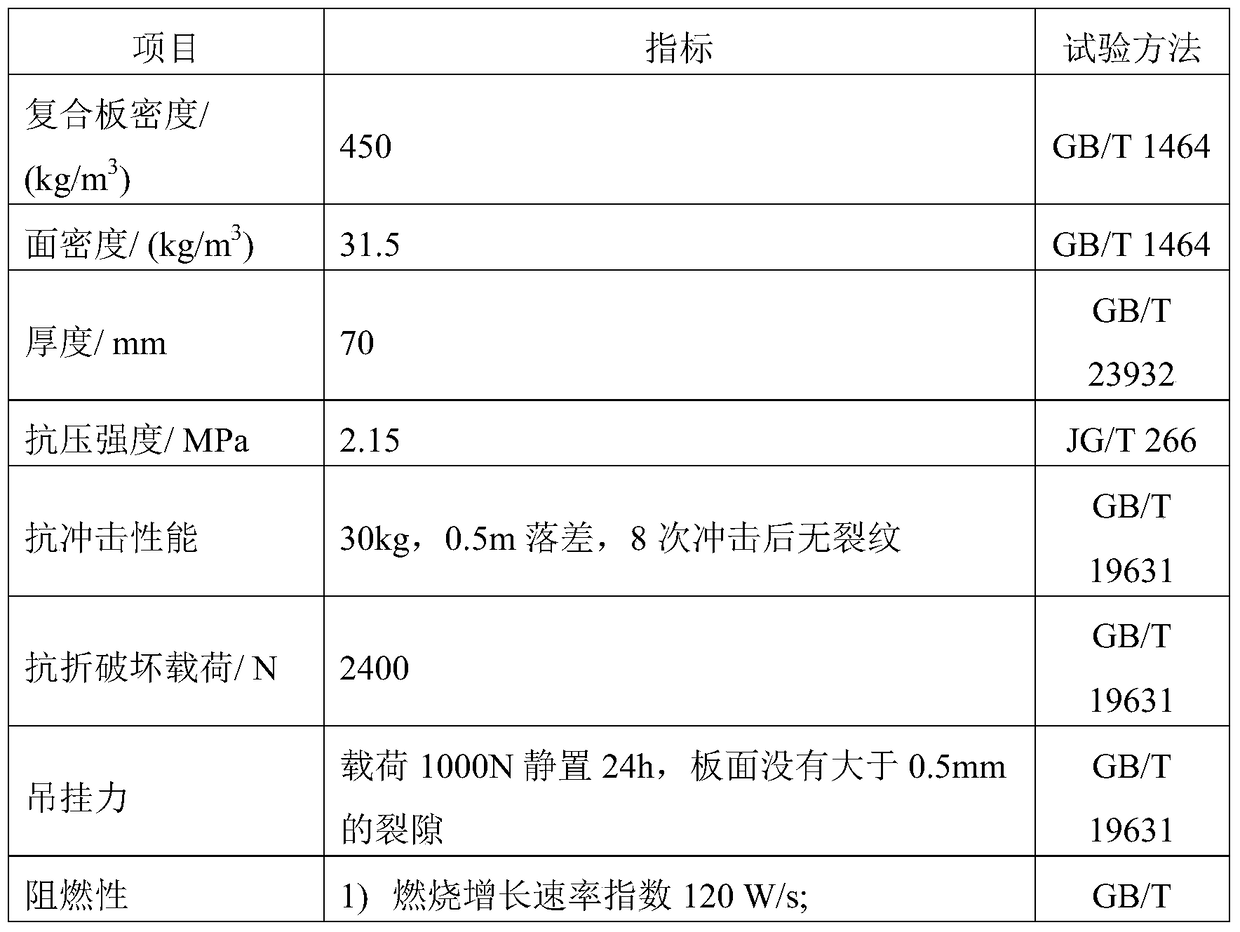

Examples

Embodiment 1

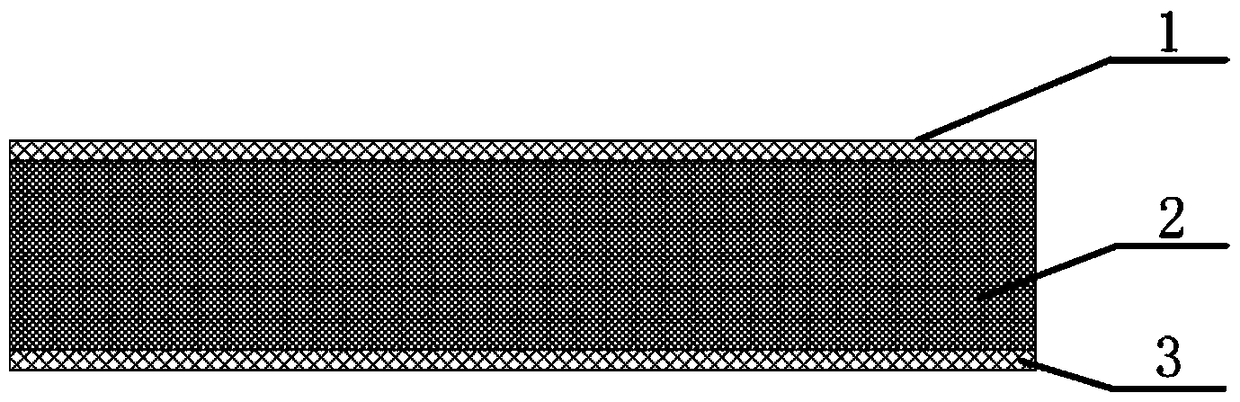

[0052] The preparation method of the flame-retardant wood fiber surface-foamed cement thermal insulation and decoration integrated board is illustrated by taking the foamed cement core material as 50 mm, and the upper and lower fiber panels as 10 mm respectively. The specific process includes the following steps:

[0053] 80 parts of #425 ordinary Portland cement, 10 parts of ceramic powder, 0.3 part of calcium stearate, 0.4 part of polycarboxylate superplasticizer, 0.2 part of polypropylene fiber, 6 parts of hydrogen peroxide solution, and 30 parts of water. First, mix the polypropylene fiber with water, and mix well, then add water reducer, cement, ceramic powder, calcium stearate, etc. Hydrogen oxide solution, under the rotation speed of 800r / min, stir rapidly for 6-8s, then put the slurry into the mold, let it stand for foaming, demould after 24 hours of hardening, and the foamed cement after demoulding continues to be cured for 7 days Carry out cutting to obtain foamed ce...

Embodiment 2

[0056] The preparation method of the flame-retardant wood fiber surface-foamed cement thermal insulation and decoration integrated board is illustrated by taking the foamed cement core material as 50 mm, and the upper and lower fiber panels as 10 mm respectively, including the following steps:

[0057] 100 parts of #425 ordinary Portland cement, 15 parts of ceramic powder, 0.4 part of calcium stearate, 0.6 part of polycarboxylate superplasticizer, 0.3 part of polypropylene fiber, 6.5 parts of hydrogen peroxide solution, and 38 parts of water. First, mix the polypropylene fiber with water, and mix well, then add water reducer, cement, ceramic powder, calcium stearate, etc. Hydrogen oxide solution, under the rotation speed of 800r / min, stir rapidly for 6-8s, then put the slurry into the mold, let it stand for foaming, demould after 24 hours of hardening, and the foamed cement after demoulding continues to be cured for 7 days Carry out cutting to obtain foamed cement board with a...

Embodiment 3

[0060] The preparation method of the flame-retardant wood fiber surface-foamed cement thermal insulation and decoration integrated board is illustrated by taking the foamed cement core material as 50 mm, and the upper and lower fiber panels as 10 mm respectively, including the following steps:

[0061] 100 parts of #425 ordinary Portland cement, 15 parts of ceramic powder, 0.4 part of calcium stearate, 0.8 part of polycarboxylate superplasticizer, 0.3 part of polypropylene fiber, 6 parts of hydrogen peroxide solution, and 42 parts of water. First, mix the polypropylene fiber with water, and mix well, then add water reducer, cement, ceramic powder, calcium stearate, etc. Hydrogen oxide solution, under the rotation speed of 800r / min, stir rapidly for 6-8s, then put the slurry into the mold, let it stand for foaming, demould after 24 hours of hardening, and the foamed cement after demoulding continues to be cured for 7 days Carry out cutting to obtain foamed cement board with a d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com