Woodiness function gradient laminate for high size-stability structure and manufacturing method of woodiness function gradient laminate for high size-stability structure

A dimensional stability and functional gradient technology, applied in the field of wood structure, can solve the problems of high finished product, short service period, poor mechanical properties and durability performance of general products, and achieve good dimensional stability, large gel content, internal low stress effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

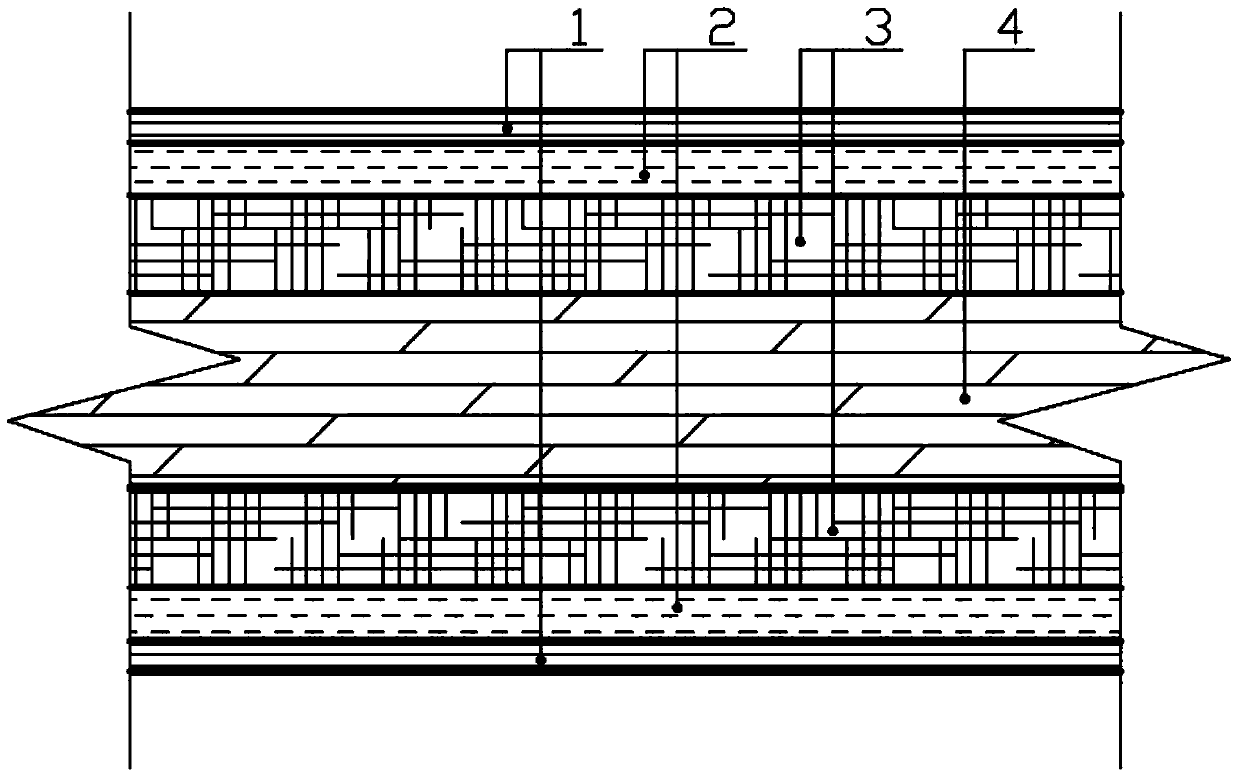

[0056] Such as figure 1 As shown, a wooden functionally graded laminate for a high dimensional stability structure includes a whole piece of wood veneer, wood and bamboo recombination units, wherein the whole piece of wood veneer is a surface layer board 1 and a subsurface layer board 2, The bamboo recombination unit is the outer laminate 3, and the wood recombination unit is the inner laminate 4. The odd-numbered and even-numbered single-layer boards in the laminates are impregnated with inorganic solutions A and B respectively, and the odd-numbered and even-numbered single-layer boards are in contact with each other. The gel layer formed by post-heat pressing reaction.

[0057] The A and B solutions are: one or any two or three mixed solutions of sodium water glass, potassium water glass and quaternary ammonium water glass.

[0058] The manufacturing method of the above-mentioned high dimensional stability structure with wooden functionally graded laminates comprises the fo...

Embodiment 2

[0069] A wooden functionally graded laminate for high dimensional stability structures, comprising a whole piece of wood veneer, wood and bamboo recombination units, wherein the whole piece of wood veneer is the surface layer and subsurface layer, and the bamboo recombination unit is the outer layer The panel and the wood recombination unit are inner laminates. The odd-numbered and even-numbered single-layer panels in the laminates are impregnated with inorganic solutions A and B respectively, and the odd-numbered and even-numbered single-layer panels are contacted. The gel layer formed by the heat-pressing reaction .

[0070] Described A and B solution are following compositions: A is one or any two or three mixed solutions in sodium water glass, potassium water glass and quaternary ammonium water glass, B is the mixed solution with sodium bicarbonate, ammonium bicarbonate An example is a salt solution containing bicarbonate.

[0071] The manufacturing method of the above-me...

Embodiment 3

[0082] A wooden functionally graded laminate for high dimensional stability structures, comprising a whole piece of wood veneer, wood and bamboo recombination units, wherein the whole piece of wood veneer is the surface layer and subsurface layer, and the bamboo recombination unit is the outer layer The panel and the wood recombination unit are inner laminates. The odd-numbered and even-numbered single-layer panels in the laminates are impregnated with inorganic solutions A and B respectively, and the odd-numbered and even-numbered single-layer panels are contacted. The gel layer formed by the heat-pressing reaction .

[0083] Described A and B solutions are the following compositions: A is one or any two or three mixed solutions of sodium water glass, potassium water glass and quaternary ammonium water glass, and B is an organic compound with polyaluminum phosphate as an example. Ester hardener.

[0084] The manufacturing method of the above-mentioned high dimensional stabil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com